Photosensitive chip lens assembling equipment and assembling method

A photosensitive chip and assembly equipment technology, applied in transportation and packaging, conveyor objects, televisions, etc., can solve problems such as monotonous and boring work, secondary pollution of workpieces, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

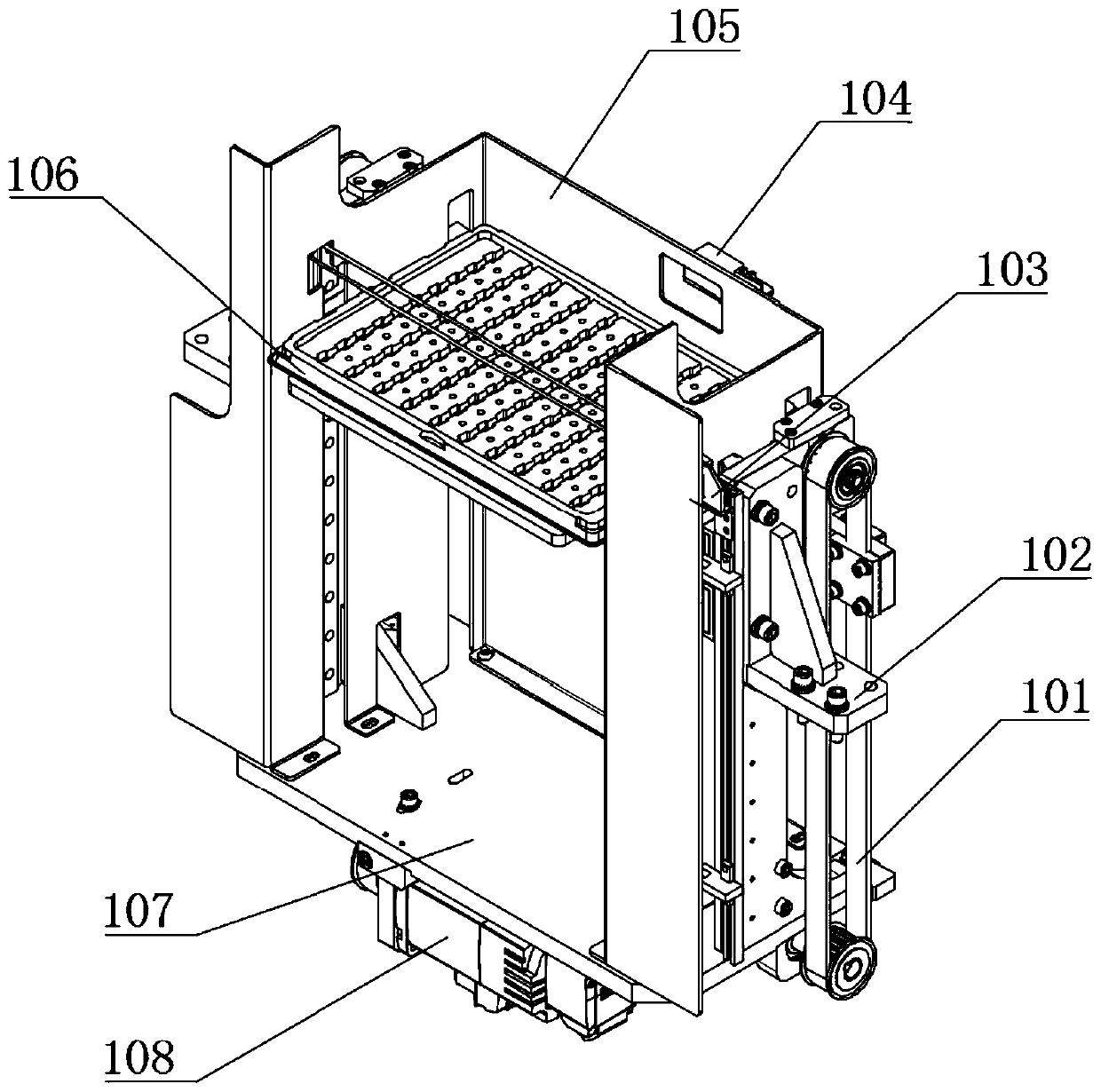

[0045] like figure 1 As shown, a photosensitive chip lens assembly equipment includes a frame 13 and a lens feeding mechanism 1 installed on the frame 13, a secondary positioning mechanism 2, an NG recovery material box 3, a lens removal robot 5, and a lens positioning mechanism 4. PCB fixture conveying line, PCB fixture shifting mechanism 9, photosensitive chip positioning mechanism 7, pressing and holding mechanism 10, automatic unloading mechanism 11, and material storage mechanism 12.

[0046] The lens feeding mechanism 1 is used to adjust the position of the lens to be grabbed by the lens removal robot 5; the secondary positioning mechanism 2 is located on the side of the lens feeding mechanism 1 and is used as a feeding transfer mechanism. Position and place the entire tray loaded with lenses grabbed by the lens removal robot 5, and allow the lens removal robot 5 to further grab a single lens in the tray, so as to achieve the purpose of precise positioning. The NG recyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com