Wheel lock cylinder

A lock cylinder and wheel piece technology, applied in the field of locks, can solve problems such as being unsuitable for mass production, high safety level, and many parts and components, and achieve the effects of good market promotion value, reduced use cost, and fewer parts and components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

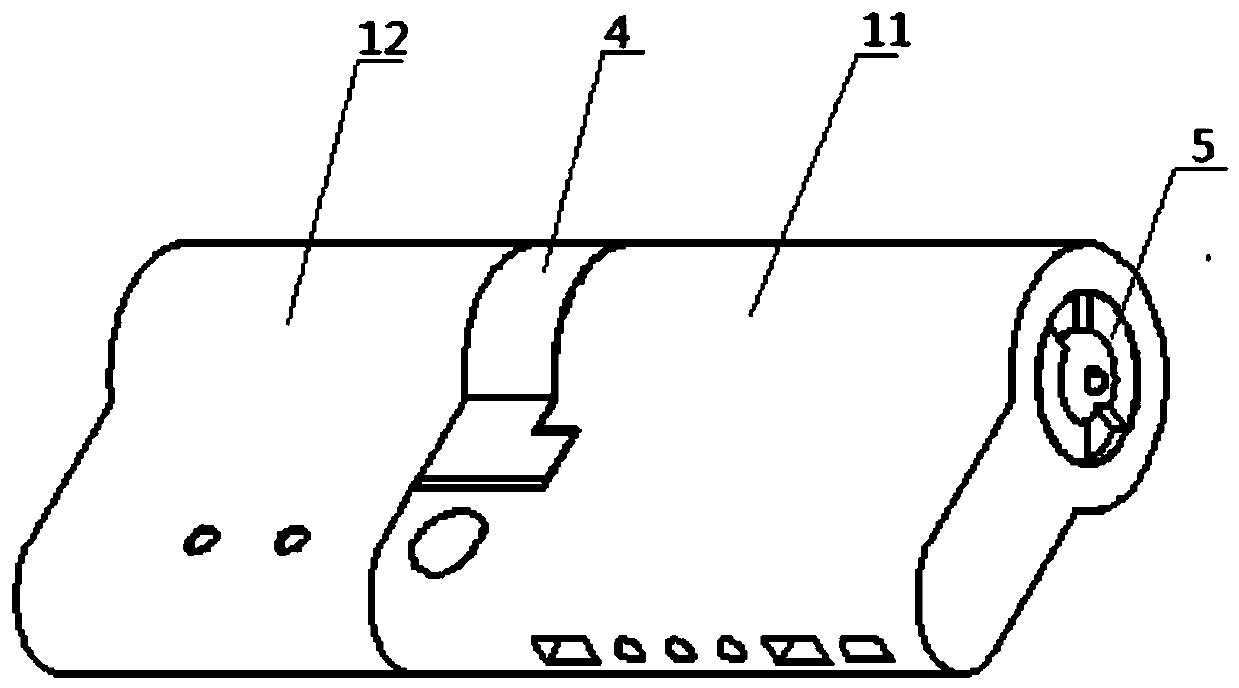

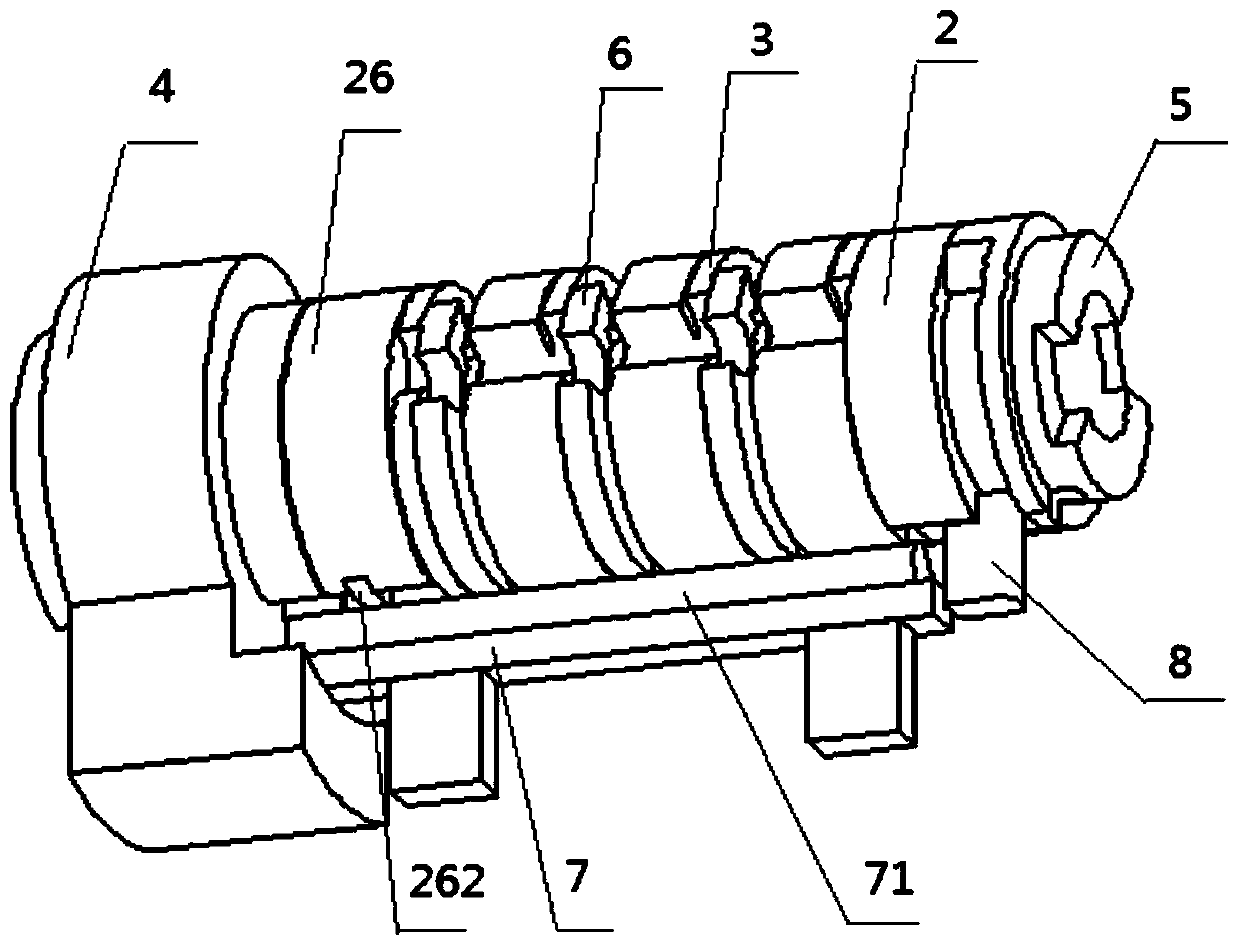

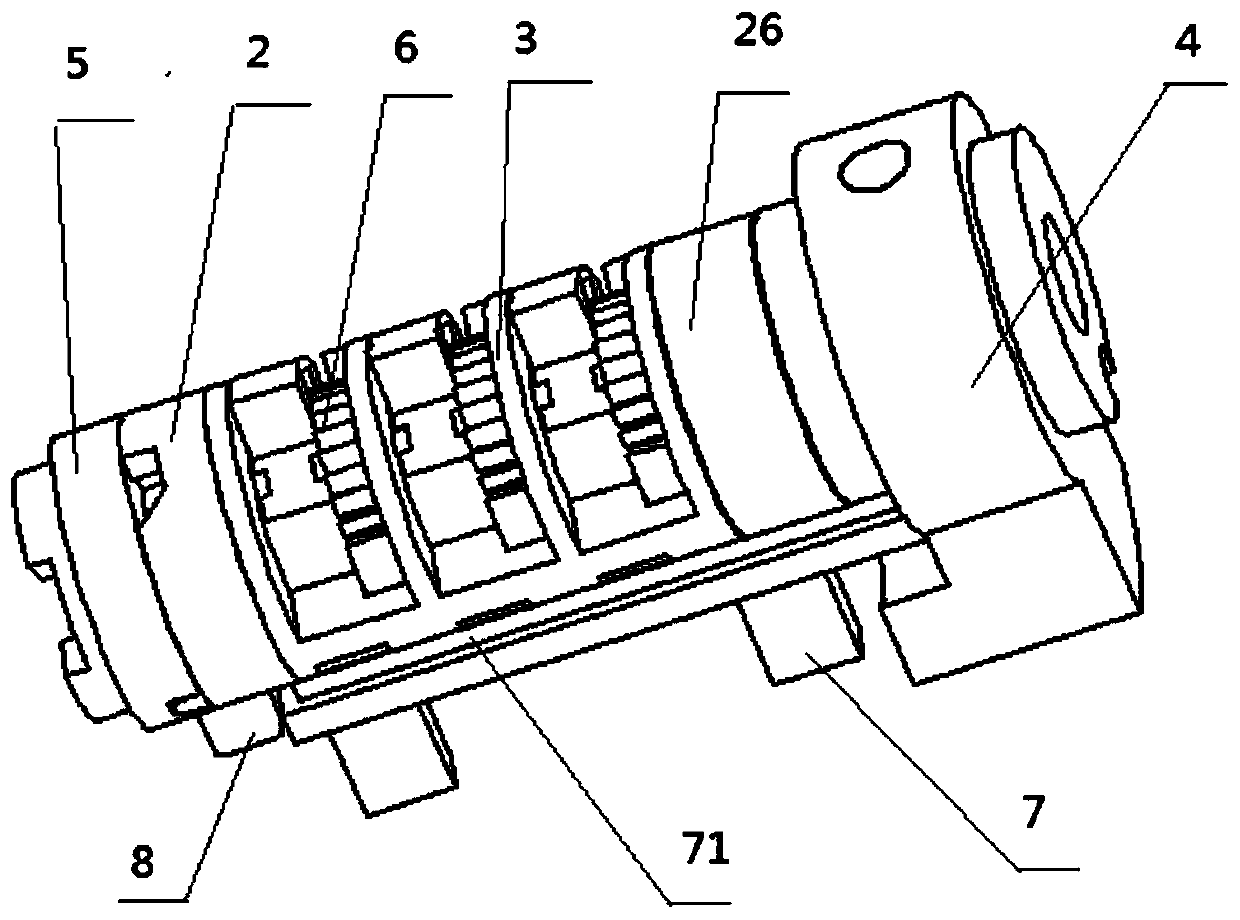

[0052] refer to Figure 1-22 , a wheel lock core, including a lock case, a lock cylinder 2, an annular hollow frame 3, a lock tongue 4, a password unit and a key starting block 5; the lock cylinder 2 is installed in the lock case, and the lock The cylinder 2 is a cylindrical structure, and the lock cylinder 2 is composed of a fixedly connected installation section 21 and a limiting head 22, the diameter of the installation section 21 is smaller than the diameter of the limiting head 22, and the key starting block 5 It is arranged at the front end of the limiting head 22, and a key insertion hole is provided through the key starting block 5 to facilitate the insertion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com