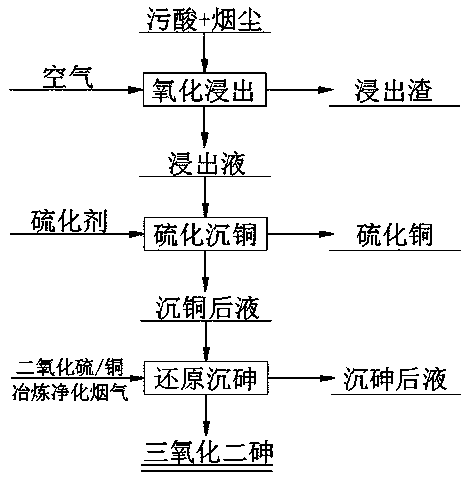

Method for comprehensively extracting arsenic from waste acid and smoke dust in copper smelting industry

A comprehensive extraction and copper smelting technology, applied in the extraction of arsenic, the comprehensive extraction of arsenic from polluted acid and smoke in the copper smelting industry, to achieve the effect of maximizing resource utilization and maximizing harmlessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Oxidation leaching

[0024] Slurry acid and smoke dust are slurried according to the liquid-solid ratio (the ratio of liquid volume L to solid weight Kg) 3:1, the temperature is 80°C, air is introduced, the air flow rate is 3 L / min, oxidation leaching is carried out for 4 hours, and the reaction is carried out after the reaction is completed. The leachate and filter residue are obtained by solid-liquid separation, the leachate enters the next process, and the filter residue is used to further recover lead and bismuth. The leaching rates of copper and arsenic were 95.5% and 94.1%, respectively.

[0026] According to the molar ratio of the copper content of the leachate to the sulfur of the vulcanizing agent is 1:1.1, sodium sulfide solution is added to the leachate, the temperature is 70°C, and the reaction is carried out for 2 hours. The copper liquid enters the next process, and the copper sulfide is decopper smelted to recover copper. ...

Embodiment 2

[0030] 1. Oxidation leaching

[0031] Slurry acid and smoke dust are slurried according to the liquid-solid ratio (the ratio of liquid volume L to solid weight Kg) 4:1, the temperature is 90 ° C, air is introduced, the air flow rate is 4 L / min, oxidation leaching is carried out for 5 hours, and the reaction is carried out after the reaction is completed. The leachate and filter residue are obtained by solid-liquid separation, the leachate enters the next process, and the filter residue is used to further recover lead and bismuth. The leaching rates of copper and arsenic were 95.8% and 94.3%, respectively.

[0032] 2. Copper sulfide

[0033] According to the molar ratio of the copper content of the leachate to the sulfur of the vulcanizing agent is 1:1.2, sodium sulfide solution is added to the leachate, the temperature is 80°C, and the reaction is carried out for 1 hour. The copper liquid enters the next process, and the copper sulfide is decopper smelted to recover copper. ...

Embodiment 3

[0037] 1. Oxidation leaching

[0038] Slurry acid and smoke dust are slurried according to the liquid-solid ratio (the ratio of liquid volume L to solid weight Kg) 5:1, the temperature is 90°C, air is introduced, the air flow rate is 5 L / min, oxidation leaching is carried out for 6 hours, and the reaction is carried out after the reaction is completed. The leachate and filter residue are obtained by solid-liquid separation, the leachate enters the next process, and the filter residue is used to further recover lead and bismuth. The leaching rates of copper and arsenic were 96.3% and 95.7%, respectively.

[0039] 2. Copper sulfide

[0040] According to the molar ratio of the copper content of the leachate to the sulfur of the vulcanizing agent is 1:1.2, sodium sulfide solution is added to the leachate, the temperature is 70 ° C, and the reaction is carried out for 1 hour. The copper liquid enters the next process, and the copper sulfide is decopper smelted to recover copper. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com