A fixing device for the production of carbon-carbon insulation cylinder materials

A technology for fixing devices and heat preservation cylinders, applied in positioning devices, storage devices, feeding devices, etc., can solve the problems of die forming size deviation, unstable heat preservation cylinder fixation, low product yield rate, etc., to improve yield rate, structure The effect of simple, fixed way fastening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

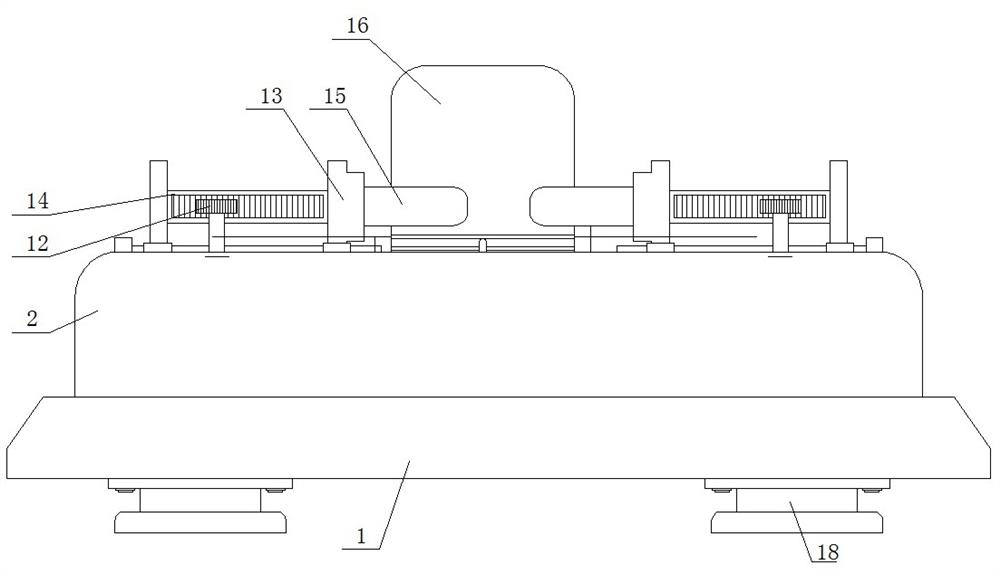

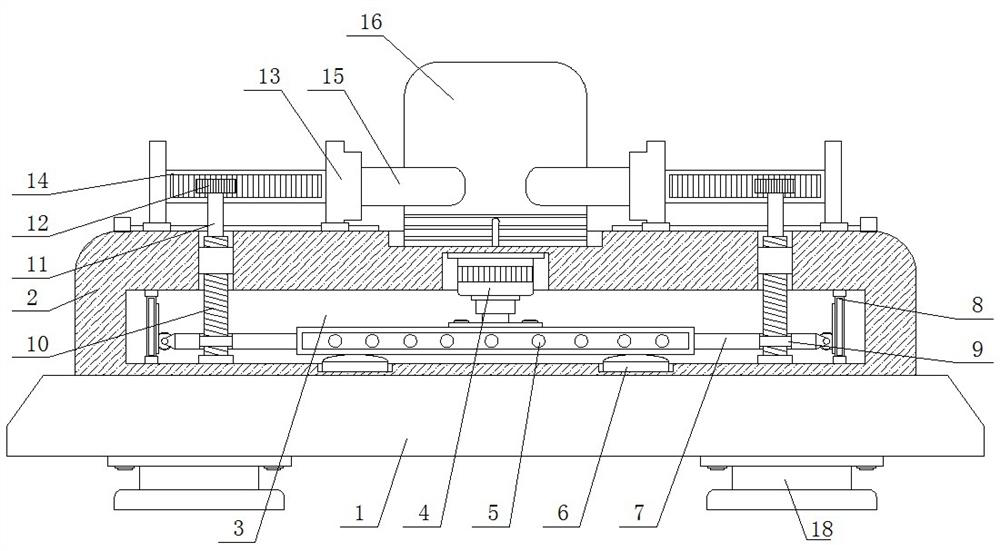

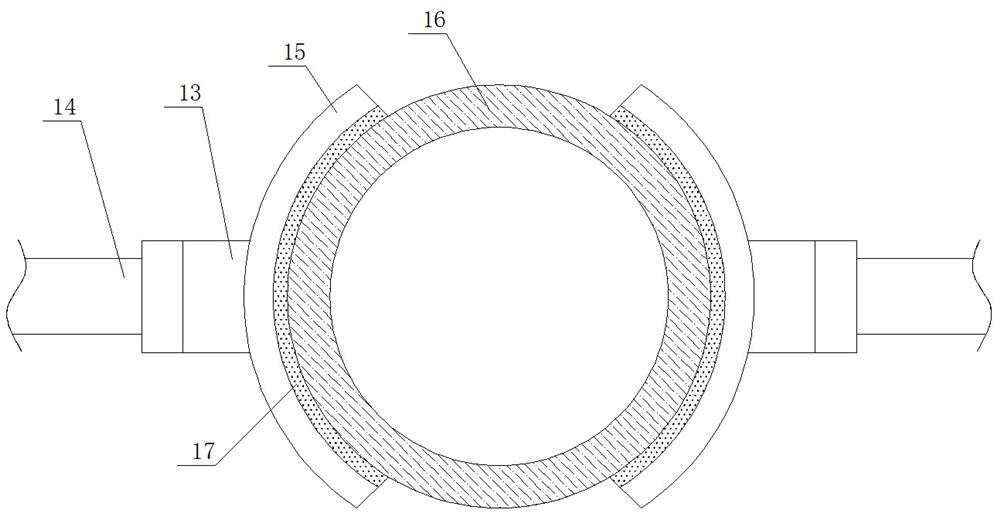

[0021] refer to Figure 1-3 , a kind of fixing device for the production of carbon-carbon insulation cylinder materials, including a base 1, a fixing seat 2 is fixedly installed on the top of the base 1, a fixing cavity 3 is arranged on the fixing seat 2, and a push rod is fixedly installed on the inner wall of the top of the fixing cavity 3 The motor 4 and the output shaft of the push rod motor 4 are welded with a pressure plate 5, and both sides of the pressure plate 5 are fixedly equipped with a connecting plate 7, and a screw nut 9 is fixedly installed on the connecting plate 7, and the bottom of the fixed cavity 3 The inner wall is rotationally connected with two symmetrically arranged ball screws 10, and the two ball screws 10 respectively pass through the two screw nuts 9 and are threadedly connected with the screw nuts 9, and the top inner wall of the fixed cavity 3 is provided with symmetrically arranged two through holes, and the tops of the two ball screws 10 respec...

Embodiment 2

[0028] refer to Figure 1-3 , a kind of fixing device for the production of carbon-carbon insulation cylinder materials, including a base 1, the top of the base 1 is fixed with a fixing seat 2 by screws, the fixing seat 2 is provided with a fixing cavity 3, and a pusher is welded on the inner wall of the top of the fixing cavity 3. The rod motor 4 and the output shaft of the push rod motor 4 are welded with a pressure plate 5, and both sides of the pressure plate 5 are fixed with a connecting plate 7 by screws, and a screw nut 9 is welded on the connecting plate 7, and the fixed cavity 3 Two symmetrically arranged ball screws 10 are connected to the inner wall of the bottom of the housing through bearing rotation, and the two ball screws 10 respectively pass through the two screw nuts 9 and are threadedly connected with the screw nuts 9. On the top inner wall of the fixed cavity 3 There are two through holes arranged symmetrically, and the tops of the two ball screws 10 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com