Seafood-flavor curry sauce

A technology for curry sauce and flavor, applied in food ingredients as odor modifiers, food science, applications, etc., can solve the problems of single taste and insufficient fragrance persistence, and achieve the improvement of aroma and flavor, increase appetite, and maintain flavor and color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

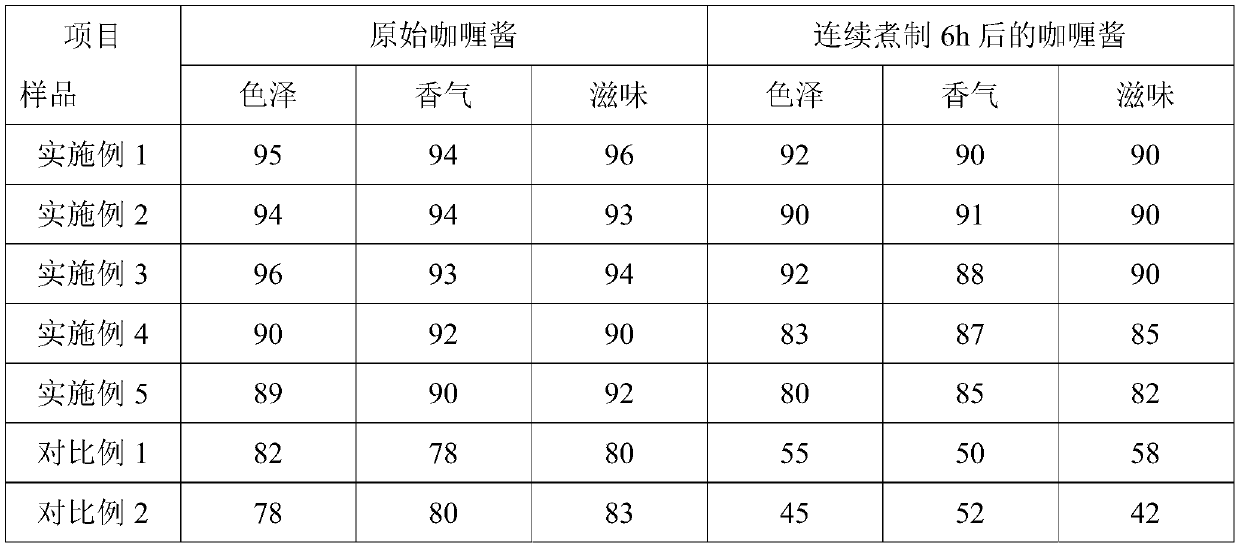

Examples

Embodiment 1

[0022] A seafood-flavored curry sauce, comprising the following raw material components in parts by weight: 600 parts of soybean oil, 70 parts of curry powder, 500 parts of onion paste, 70 parts of garlic paste, 100 parts of salt, 300 parts of sugar, and 35 parts of fish hydrolyzate , 28 parts of turmeric powder, 5 parts of cumin, 3 parts of lemongrass powder, 210 parts of modified starch, 3 parts of pepper powder, 1 part of tangerine peel powder, 2 parts of galangal powder, 4 parts of nutmeg powder, and 2 parts of cumin powder; Each part by weight is calculated as 1 g.

[0023] The above fish hydrolyzate is obtained by the following method: the collected fish scraps are cleaned and crushed; then water at 40°C that is 5 times the total mass of the scraps after crushing is added, and 0.3% of the total mass of the scraps after crushing is added. Hydrolase, the hydrolase is made by mixing pepsin and papain at an enzyme activity ratio of 1:1; keep the temperature at 40°C and keep ...

Embodiment 2

[0028] A seafood-flavored curry sauce, comprising the following raw material components in parts by weight: 850 parts of soybean oil, 70 parts of curry powder, 550 parts of mashed onion, 80 parts of mashed garlic, 100 parts of salt, 400 parts of sugar, and 40 parts of fish hydrolyzate , 30 parts of turmeric powder, 6 parts of cumin powder, 3 parts of lemongrass powder, 250 parts of modified starch, 4 parts of pepper powder, 2 parts of tangerine peel powder, 3 parts of galangal powder, 6 parts of nutmeg powder, and 2 parts of cumin powder; Each part by weight is calculated as 2g.

[0029] The above fish hydrolyzate is prepared by the following method: the collected fish scraps are cleaned and crushed; then water at 45°C that is 3 times the total mass of the scraps after crushing is added, and 0.5% of the total mass of the scraps after crushing is added. Hydrolase, the hydrolase is made by mixing pepsin and papain according to the enzyme activity ratio of 1:2; keep the temperatu...

Embodiment 3

[0034]A seafood-flavored curry sauce, comprising the following raw material components in parts by weight: 700 parts of peanut oil, 50 parts of curry powder, 400 parts of mashed onion, 60 parts of mashed garlic, 80 parts of salt, 350 parts of sugar, 30 parts of fish hydrolyzate, 25 parts of turmeric powder, 5 parts of cumin, 2 parts of lemongrass powder, 240 parts of modified starch, 2 parts of pepper powder, 1 part of tangerine peel powder, 3 parts of galangal powder, 4 parts of nutmeg powder, and 1 part of cumin powder; Parts by weight are based on 5g.

[0035] The above fish hydrolyzate is prepared by the following method: the collected fish scraps are cleaned and crushed; then water at 50°C that is 4 times the total mass of the scraps after crushing is added, and 0.4% of the total mass of the scraps after crushing is added. Hydrolase, the hydrolase is made by mixing pepsin and papain according to the enzyme activity ratio of 1:1.2; keep the temperature at 50°C and keep sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com