Maintenance method and device for IPC equipment

A technology of equipment and objects, applied in the field of IPC equipment maintenance methods and devices, can solve problems such as inconvenient operation, potential safety hazards, and inability to locate faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

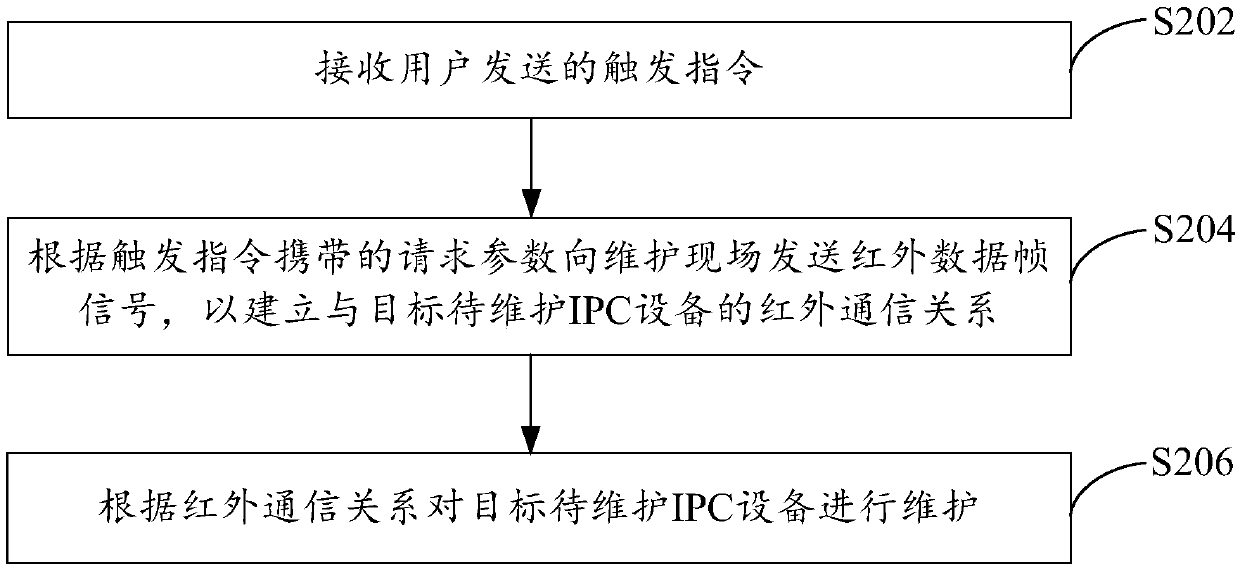

[0062] A kind of maintenance method of IPC equipment, refer to figure 2 , applied to the maintenance end, the method includes:

[0063] S202. Receive a trigger instruction sent by the user, wherein the trigger instruction carries a request parameter for infrared communication with the IPC device to be maintained;

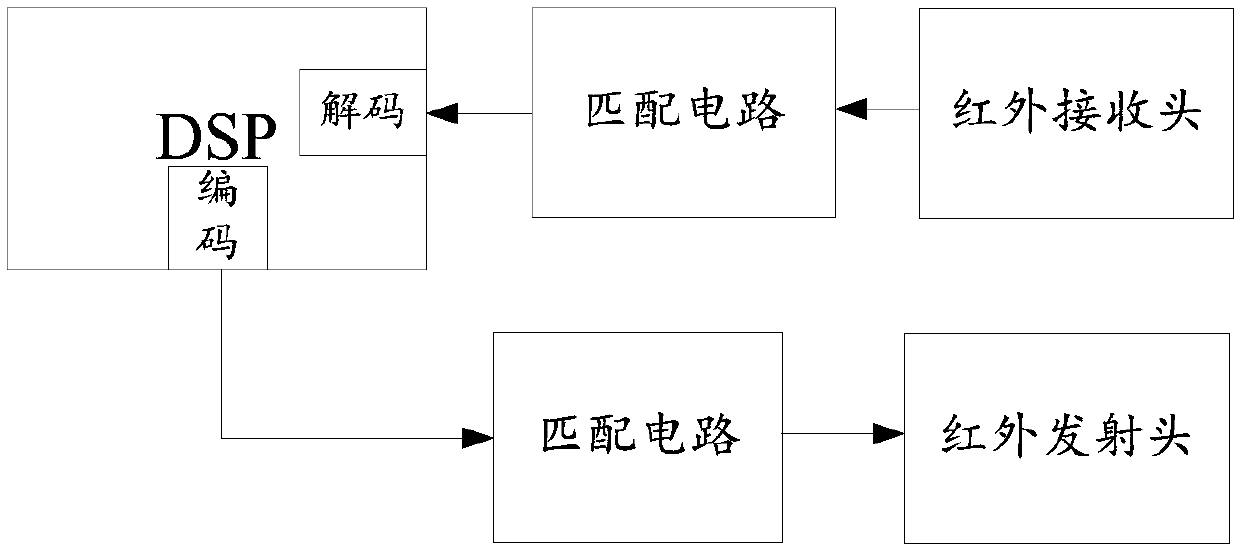

[0064] In the embodiment of the present invention, the maintenance of the IPC equipment is carried out in the form of an infrared pair of tubes. Infrared receiving circuit (including infrared receiving head, matching circuit and decoding unit) and infrared transmitting circuit (including infrared emitting head, matching circuit and encoding unit) are respectively set on IPC equipment and maintenance end (as shown in Fig. 3 (a) and Fig. 3 ( As shown in b), the wireless maintenance of the IPC equipment at the maintenance site is realized. Since the infrared communication receives a 38Khz pulse modulation signal, only one signal is allowed to be sent at the same tim...

Embodiment 2

[0137] A kind of maintenance device of IPC equipment, this device is arranged on the maintenance end, refer to Figure 10 , the device consists of:

[0138] The receiving module 11 is configured to receive a trigger instruction sent by the user, wherein the trigger instruction carries a request parameter for infrared communication with the IPC device to be maintained;

[0139] The sending module 12 is used to send an infrared data frame signal to the maintenance site according to the request parameter carried by the trigger command, so as to establish an infrared communication relationship with the target IPC device to be maintained, wherein there is an IPC device to be maintained in the maintenance site, and the target IPC device to be maintained The number of devices is one;

[0140] The maintenance module 13 is configured to maintain the target IPC device to be maintained according to the infrared communication relationship.

[0141] In the maintenance device for IPC equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com