Inclination nanorod-based circular dichroism structure

A circular dichroism and nanorod technology is applied in the field of circular dichroism structure to achieve the effects of being convenient for mass production, simple in structure and simple in production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The directions described in the examples: front and back are figure 1 In the y direction shown, left and right are figure 1 shown in the x-direction.

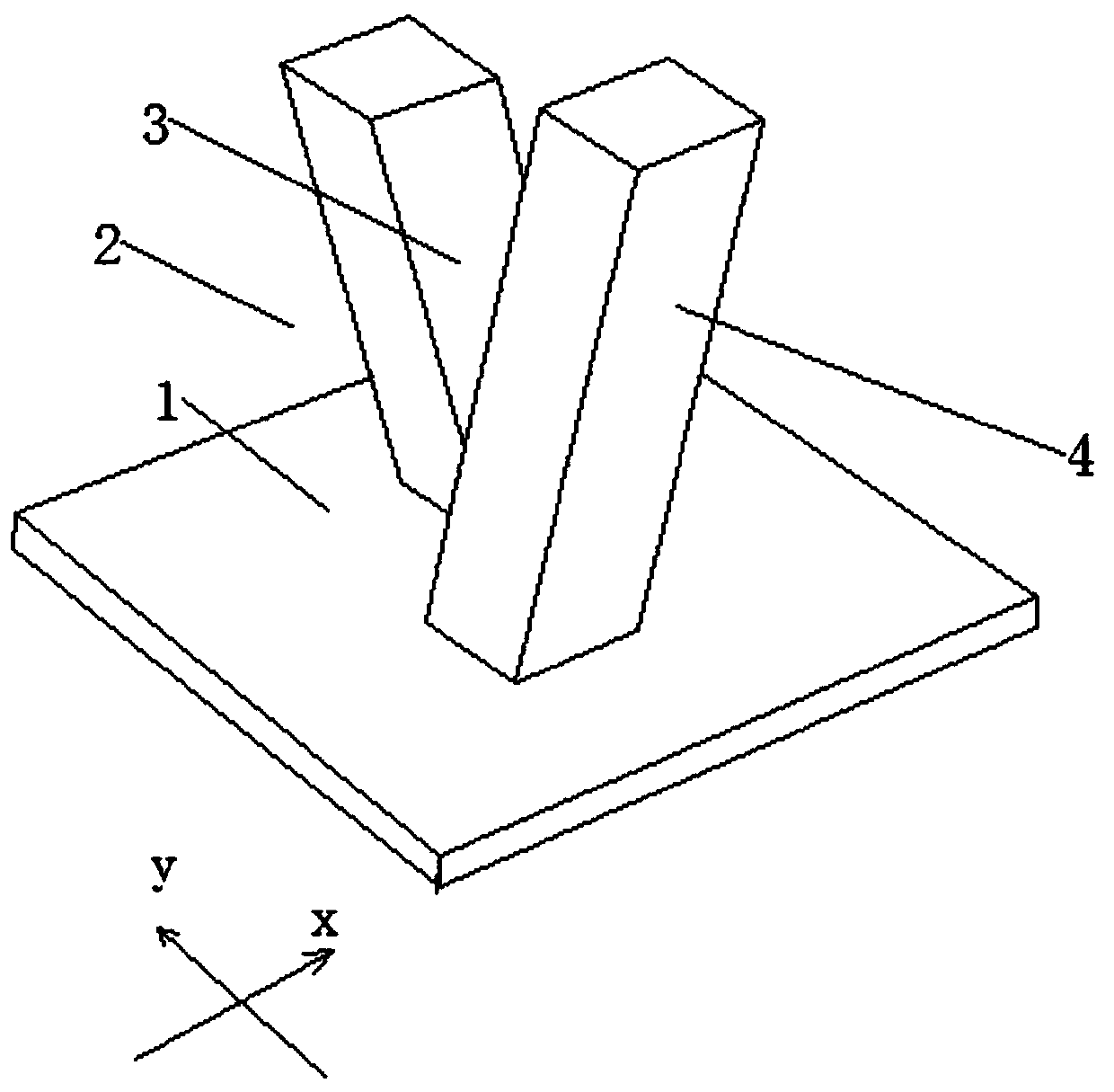

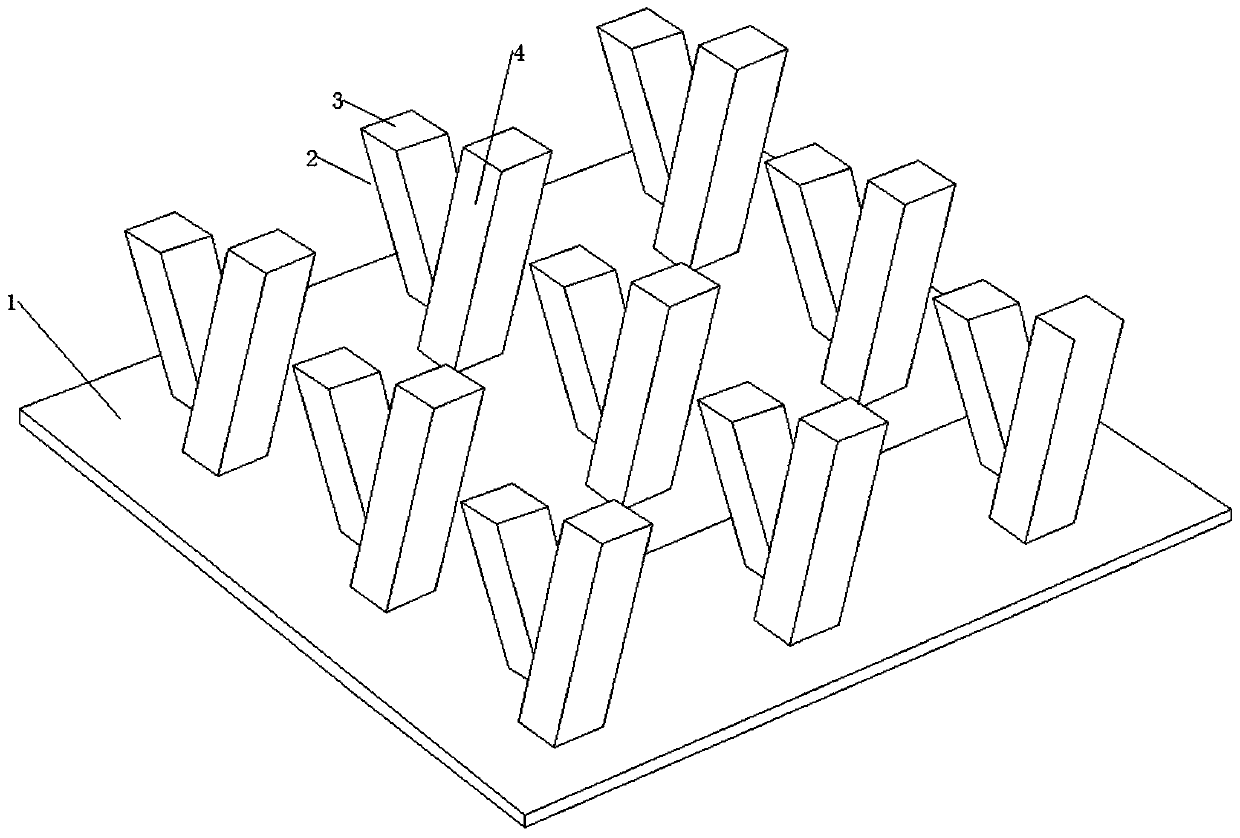

[0028] This embodiment provides a figure 2 The shown circular dichroic structure based on inclined nanorods includes a substrate layer 1, and the substrate layer 1 mainly plays the role of light transmission and support. Therefore, the substrate 5 can be made of silicon dioxide or glass with good light transmission made; as figure 1 As shown, the substrate layer 1 is provided with periodically arranged structural units 2, and the structural units 2 include first metal nanorods 3 and second metal nanorods 4; the back side of the first metal nanorods 3 is connected to The front sides of the second metal nanorods 4 are adjacent; the first metal nanorods 3 are inclined to the left, and the second metal nanorods 4 are inclined to the right, so that the first metal nanorods 3 and the second An included angle is formed bet...

Embodiment 2

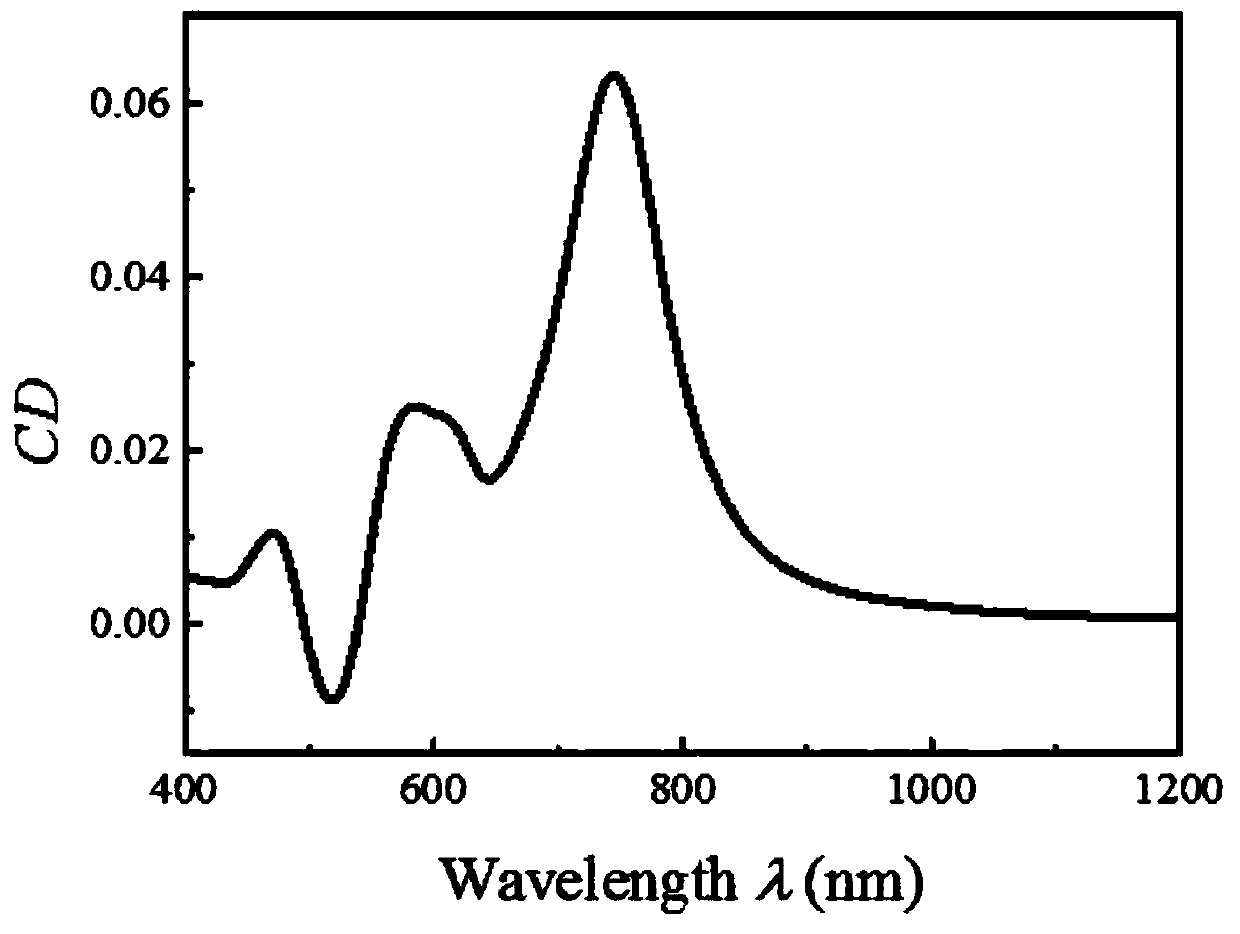

[0036] On the basis of Example 1, such as image 3 As shown, the period of arrangement of the structural unit 2 is 200nm; and the dimensions of the first metal nanorod 3 and the second metal nanorod 4: length×width×height are 40nm×40 nm×60nm, and the thickness of the substrate layer 1 is 10nm The gap between the first metal nanorod 3 and the second metal nanorod 4 is 20nm; the angle formed by the first metal nanorod 3 and the second metal nanorod 4 is 60°; the wavelength of the incident light is between 400nm and 1200nm When the circular dichroism display diagram, it can be seen from the figure that when the wavelength of the incident light is 740nm, the circular dichroism is the most prominent, and the best circular dichroism can reach 0.06; when the wavelength of the incident light is 600nm, There is also a peak of circular dichroism, and the circular dichroism can be only about 0.03. The circular dichroism of the circular dichroism structure based on inclined nanorods is re...

Embodiment 3

[0038] On the basis of Example 1, such as Figure 4 As shown, the period of arrangement of the structural unit 2 is 200nm; and the dimensions of the first metal nanorod 3 and the second metal nanorod 4: length×width×height are 40nm×40 nm×60nm, and the thickness of the substrate layer 1 is 10nm The gap between the first metal nanorod 3 and the second metal nanorod 4 is 0nm; the angle formed by the first metal nanorod 3 and the second metal nanorod 4 is 20°; the wavelength of the incident light is between 400nm and 1200nm When the circular dichroism display diagram, it can be seen from the figure that when the wavelength of the incident light is 840nm, the circular dichroism is the most prominent, and the best circular dichroism can be close to 0.13; when the wavelength of the incident light is 600nm, There is also a peak of circular dichroism, and the circular dichroism can be only about 0.03. The circular dichroism of the circular dichroism structure based on inclined nanorods...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com