A treatment method for metallographic samples with crack defects after etching

A metallographic sample and processing method technology, applied in the field of physical and chemical inspection, can solve the problems of pollution, inability to effectively observe and accurately analyze the microstructure and morphology, and achieve the purpose of avoiding corrosion of the grinding surface, protecting the metallographic grinding surface, show real effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) The SA-210C failure sample with crack defects is ground and polished to obtain a metallographic polished sample with a metallographic grinding surface, and then it is etched with an etchant of nitric acid-alcohol solution, Rinse with clean water after etching, then drip with absolute ethanol and dry with hot air;

[0029] (2) Soak the dried sample in the aqueous solution of EDTA and urotropine for 10 min, wherein the mass concentration of EDTA in the aqueous solution of EDTA and urotropine is 2%, and the mass concentration of urotropine is 0.5% %;

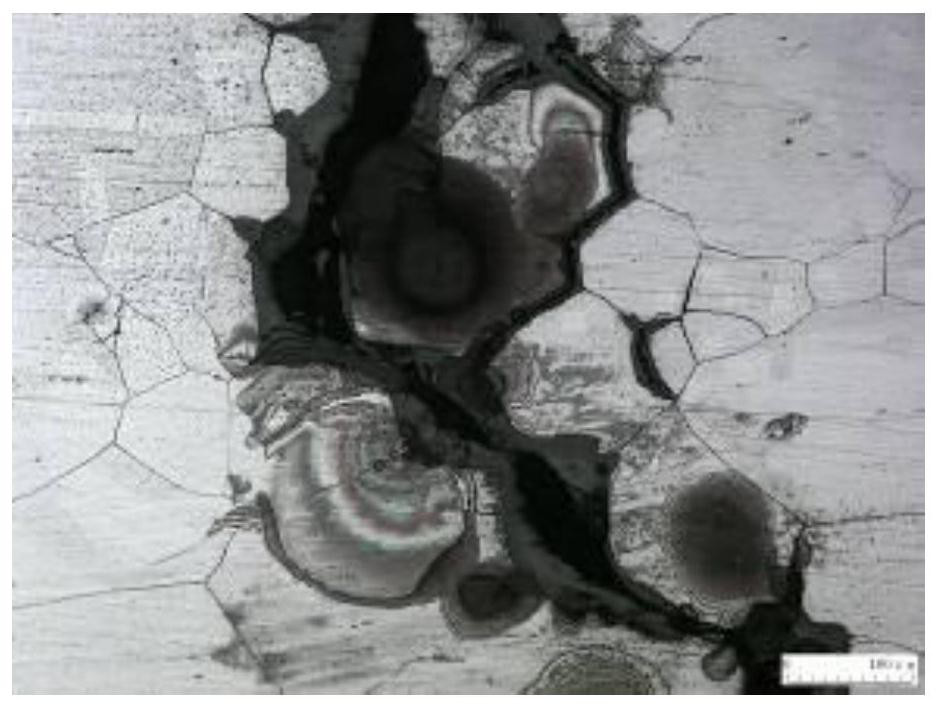

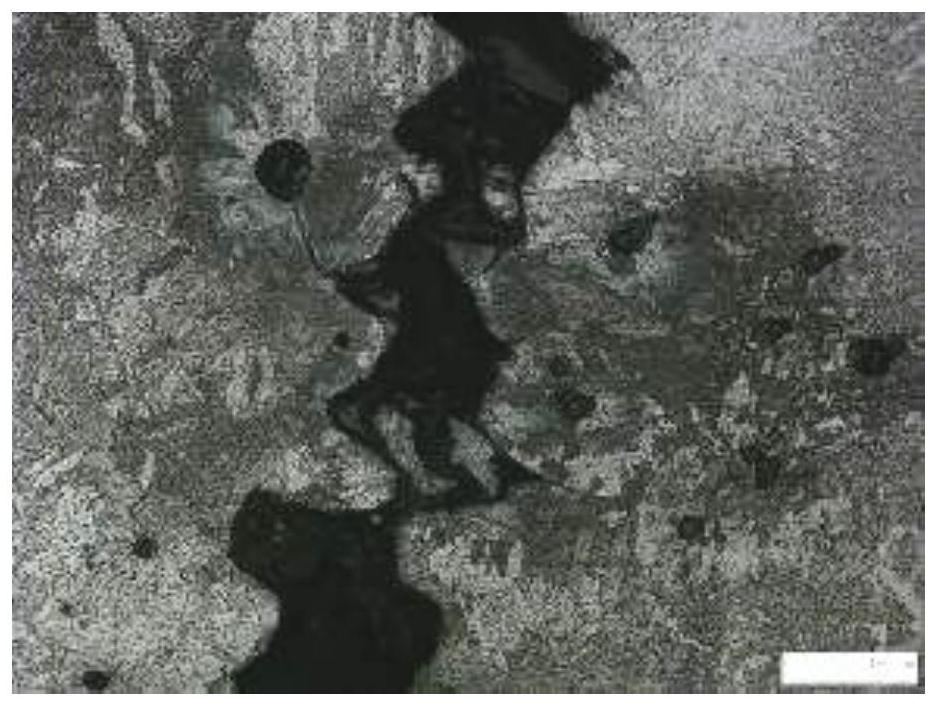

[0030] (3) Take out the soaked sample, drop absolute ethanol on it, blow it with hot air until the surface temperature of the sample is 40°C, and then apply a layer of varnish coating with a thickness of 1mm on the cracked area of the sample at one time; After the coating on the surface of the sample is naturally dried and solidified, it is observed under an optical microscope, and the microstructure of the crack defe...

Embodiment 2

[0032] (1) The failure sample of 12Cr1MoVG with crack defects is ground and polished to obtain a metallographic polished sample with a metallographic grinding surface, and then it is etched with an etchant of nitric acid-alcohol solution to etch it. Afterwards, rinse with clean water, then drop absolute ethanol and dry with hot air;

[0033] (2) soak the dried sample in the aqueous solution of EDTA and urotropine for 20min, wherein the mass concentration of EDTA in the aqueous solution of EDTA and urotropine is 4.5%, and the mass concentration of urotropine is 0.9% %;

[0034](3) Take out the soaked sample, drop absolute ethanol and blow it with hot air until the surface temperature of the sample is 50°C, and then apply a layer of varnish coating with a thickness of 0.8mm on the cracked area of the sample at one time After the coating on the surface of the sample is naturally dried and solidified, it is observed under an optical microscope, and the microstructural morpholog...

Embodiment 3

[0036] (1) The failure sample of HR3C with crack defects is ground and polished to obtain a metallographic polished sample with a metallographic grinding surface, and then it is etched with an etchant of copper chloride-hydrochloric acid aqueous solution, Rinse with clean water after etching, then drop absolute ethanol and dry with hot air;

[0037] (2) soak the dried sample in the aqueous solution of EDTA and urotropine for 30min, wherein the mass concentration of EDTA in the aqueous solution of EDTA and urotropine is 3.2%, and the mass concentration of urotropine is 0.05%; %;

[0038] (3) Take out the soaked sample, drop absolute ethanol on it, blow it with hot air until the surface temperature of the sample is 60°C, and then apply a layer of smooth varnish with a thickness of 1 mm on the cracked area of the sample at one time. After the coating on the surface of the sample is naturally dried and solidified, it is observed under an optical microscope, and the microstructu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com