Method and device for upward cracking left coal pillars in residual mining area through microwave heating

A technology of leftover coal pillar and microwave heating, which is applied in mining equipment, ground mining, mining equipment, etc., can solve the problem of less application of microwave heating cracking technology, and achieve the effect of easy control, convenient operation and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

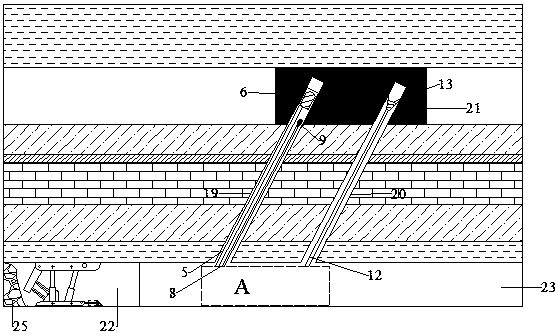

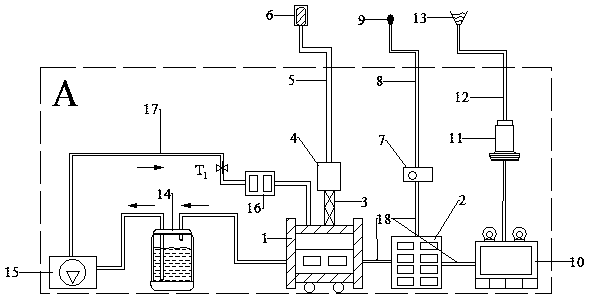

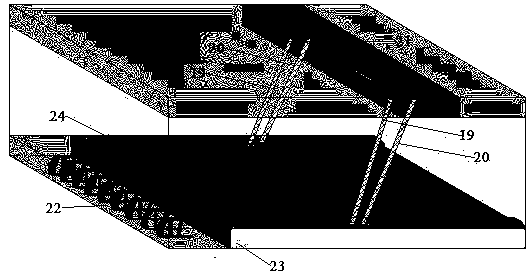

[0040] Such as figure 2 As shown, a microwave heating device for coal pillars left in the upward fracturing residual mining area includes: a high-power microwave generator, a microwave power controller, a circular waveguide, a waveguide converter, a coaxial waveguide, a microwave transmitter, and a temperature monitor Device, high temperature resistant wire, temperature sensor, data acquisition instrument, signal amplifier, signal transmission line, detection probe, water storage tank, high pressure pump, cooler, microwave generator cooling control valve;

[0041] The high-power microwave generator 1 is connected to the microwave transmitter 6 through the circular waveguide 3, the waveguide converter 4, and the coaxial waveguide 5; the high-power microwave generator 1 passes the microwave energy through the circular waveguide 3, the waveguide converter 4, and the coaxial The waveguide 5 is delivered to the microwave launcher 6, and the microwave launcher 6 is responsible for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com