Expansion type fire-retardant coating and preparation method thereof

A fire-resistant coating, intumescent technology, applied in fire-resistant coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of short fire-resistant time of fire-resistant coatings, poor adhesion to steel substrates, and poor fire-proof performance. Achieve good viscoelasticity, low thermal oxidation resistance and strong bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

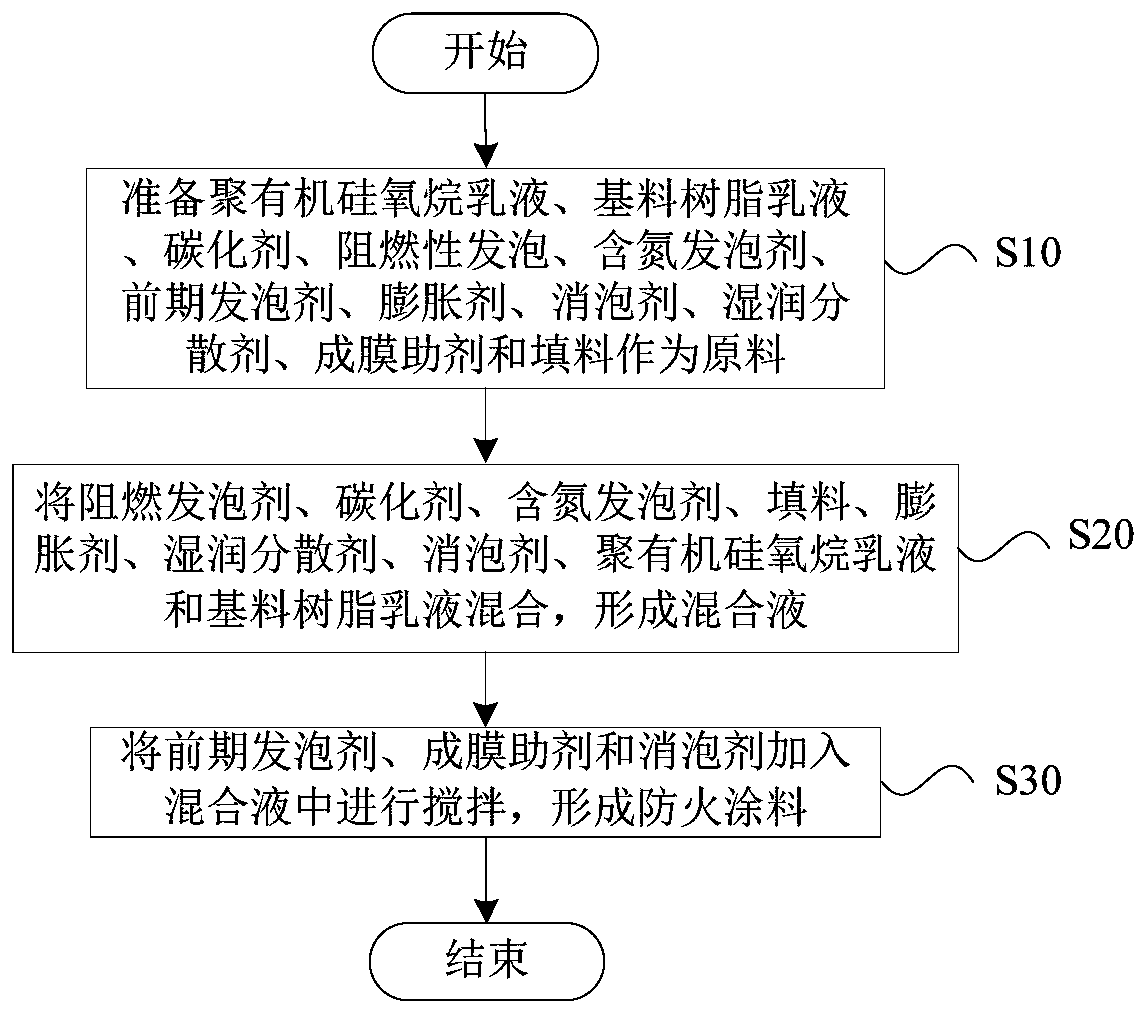

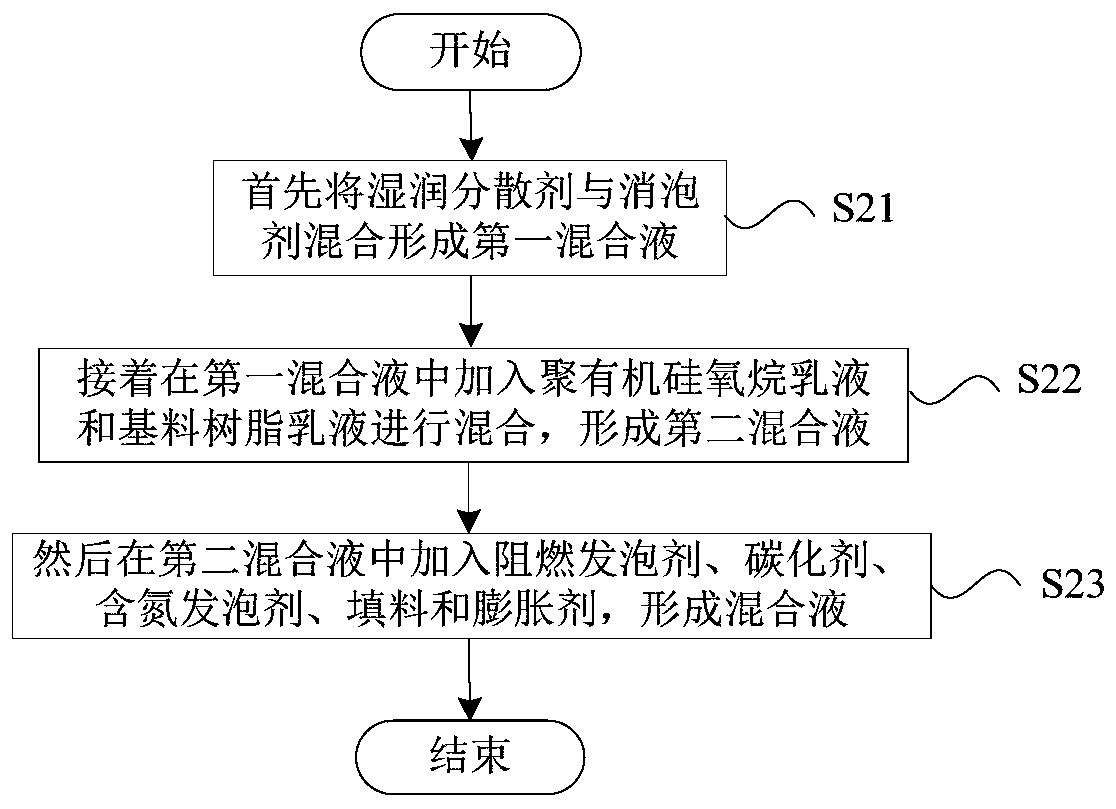

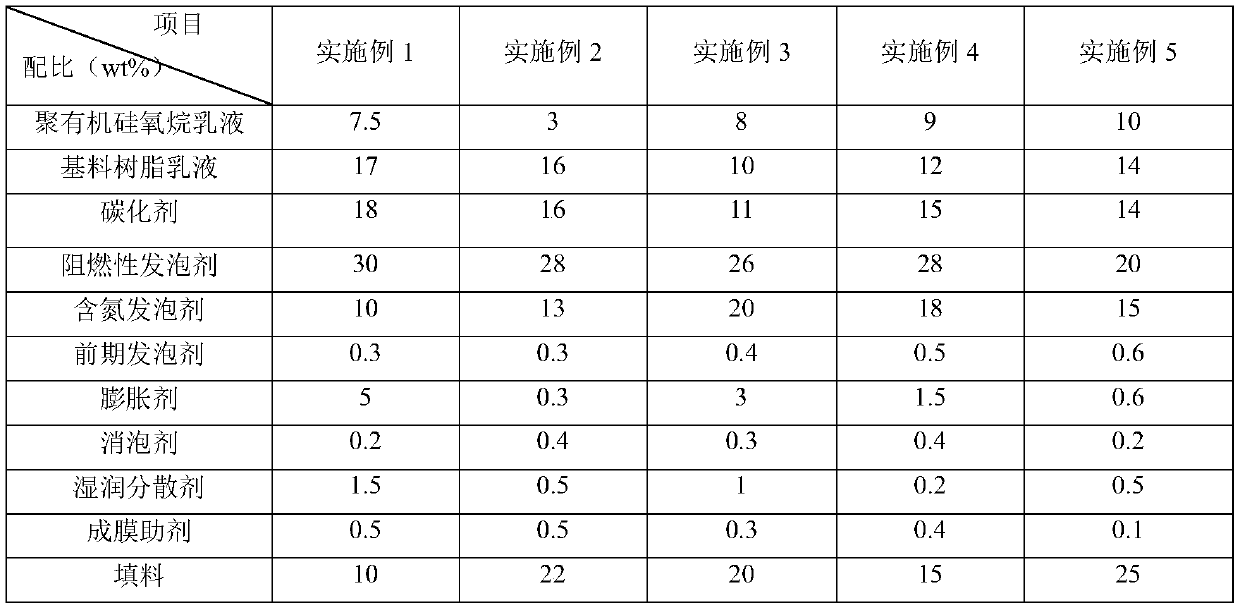

[0069] Such as figure 1 As shown, in this embodiment, the preparation method of the intumescent fireproof coating may include: preparing polyorganosiloxane emulsion, base resin emulsion, carbonizing agent, flame retardant foaming, nitrogen-containing foaming agent, pre-foaming agent Foaming agent, expansion agent, antifoaming agent, wetting dispersant, film-forming aid and filler are used as raw material (step S10); The dispersant, defoamer, polyorganosiloxane emulsion and base resin emulsion are mixed to form a mixed solution (step S20); and the pre-foaming agent, film-forming aid and defoamer are added to the mixed solution for stirring, Form fireproof paint (step S30).

[0070] In the preparation method of the intumescent fire retardant coating according to the present embodiment, by adding and mixing the above-mentioned raw materials according to a prescribed mass percentage, a fire retardant coating with prolonged burning time and improved fire retardant performance can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com