Lanthanum and titanium co-doped bismuth ferrite membrane and preparation method thereof

A thin-film preparation, bismuth ferrite technology, applied in the coating and other directions, to achieve the effects of high remanent polarization, short annealing time, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

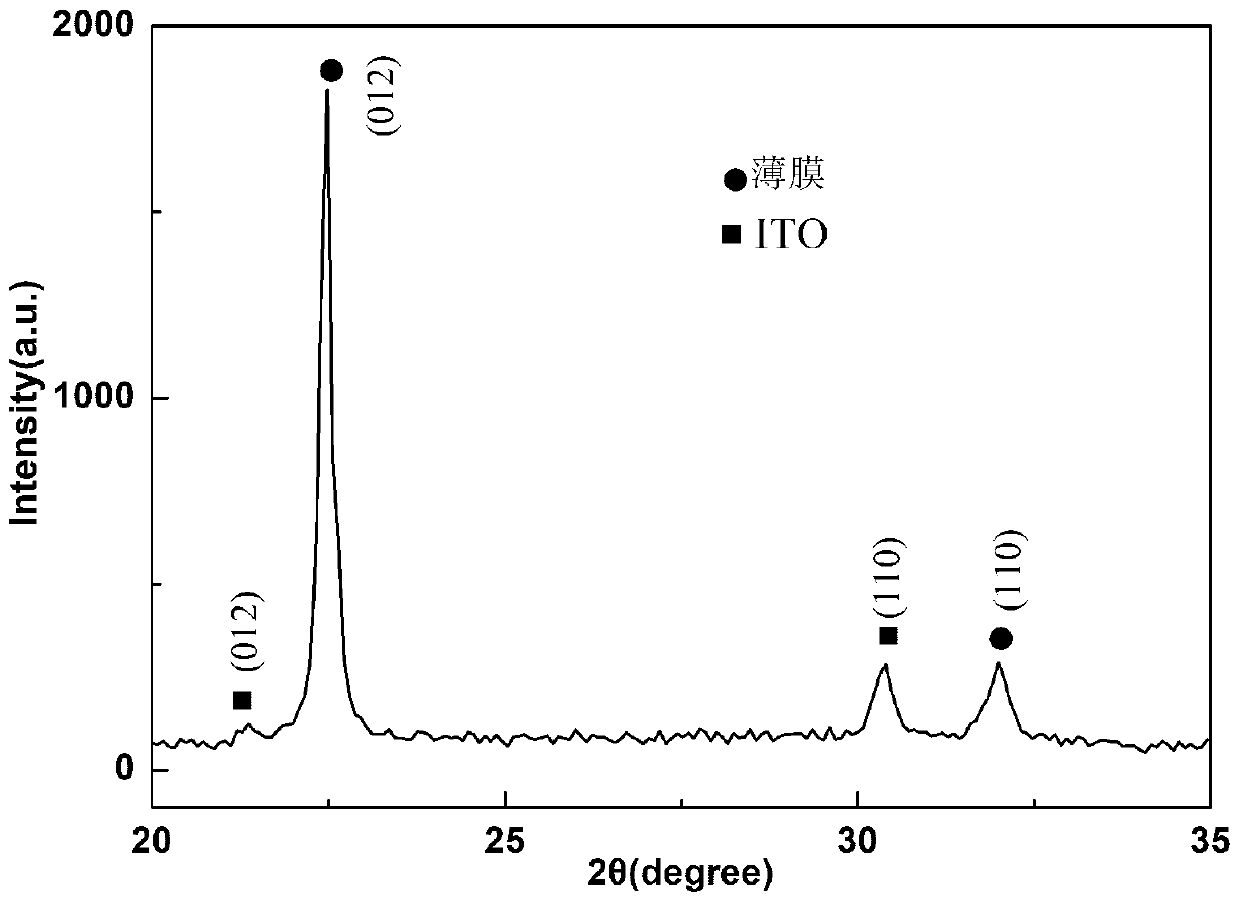

Image

Examples

Embodiment 1

[0026] A bismuth ferrite thin film co-doped with lanthanum and titanium was prepared by sol-gel and bonding layer-by-layer annealing process (1+Z)(1 –Y) La Y Fe 1-X Ti X o 3 (BLTO), that is, the ratio of each element is Bi:La:Fe:Ti:O=(1+Z)(1 –Y):Y:(1-X):X:3, the film has 10 layers in total, Each layer thickness is 100nm; Among the present invention, bismuth source, lanthanum source, iron source, titanium source are respectively bismuth nitrate, lanthanum nitrate, ferric nitrate, tetrabutyl titanate, and wherein X is the molar equivalent 0.10 of Ti element, and Y is La The molar equivalent of the element is 0.10, the element Bi is added in excess, Z is the excess percentage of Bi by weight, Z is 13% in the first to third layers, Z is 3% in the fourth to seventh layers, and the eighth layer Z is 9% in the 10th floor.

[0027] The preparation method of this thin film comprises the following steps:

[0028] 1. Preparation of precursor solution: by sol-gel method, respectivel...

Embodiment 2

[0032] A bismuth ferrite thin film co-doped with lanthanum and titanium was prepared by sol-gel and bonding layer-by-layer annealing process (1+Z)(1 –Y) La Y Fe 1-X Ti X o 3 (BLTO), that is, the ratio of each element is Bi:La:Fe:Ti:O=(1+Z)(1 –Y):Y:(1-X):X:3, the film has 12 layers in total, Each layer thickness is 110nm; Among the present invention, bismuth source, lanthanum source, iron source, titanium source are respectively bismuth nitrate, lanthanum nitrate, ferric nitrate, tetrabutyl titanate, and wherein X is the molar equivalent 0.01 of Ti element, and Y is La The molar equivalent of the element is 0.05, the element Bi is added in excess, Z is the excess percentage of Bi by weight, Z is 11% in the first to third layers, Z is 5% in the fourth to ninth layers, and the tenth layer Z is 10% to the 12th floor.

[0033] The preparation method of this thin film comprises the following steps:

[0034]1. Preparation of precursor solution: by sol-gel method, respectively w...

Embodiment 3

[0038] A bismuth ferrite thin film co-doped with lanthanum and titanium was prepared by sol-gel and bonding layer-by-layer annealing process (1+Z)(1 –Y) La Y Fe 1-X Ti X o 3 (BLTO), that is, the ratio of each element is Bi:La:Fe:Ti:O=(1+Z)(1 –Y):Y:(1-X):X:3, the film has 8 layers in total, Each layer thickness is 120nm; Among the present invention, bismuth source, lanthanum source, iron source, titanium source are respectively bismuth nitrate, lanthanum nitrate, iron nitrate, tetrabutyl titanate, and wherein X is the molar equivalent 0.03 of Ti element, Y The molar equivalent of the La element is 0.07, the element Bi is added in excess, Z is the excess percentage of Bi by weight, Z is 12% in the first to third layers, Z is 4% in the fourth to fifth layers, and Z is 4% in the fourth to fifth layers. Z is 9.5% in the 6th floor to the 8th floor.

[0039] The preparation method of this thin film comprises the following steps:

[0040] 1. Preparation of precursor solution: by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com