Multi-material automatic collecting and boxing system and packaging process thereof

A technology of automatic collection and packaging technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of no obvious improvement in production efficiency, large floor space, long transportation distance, etc., to achieve high production efficiency and land occupation. The effect of small area and less personnel requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

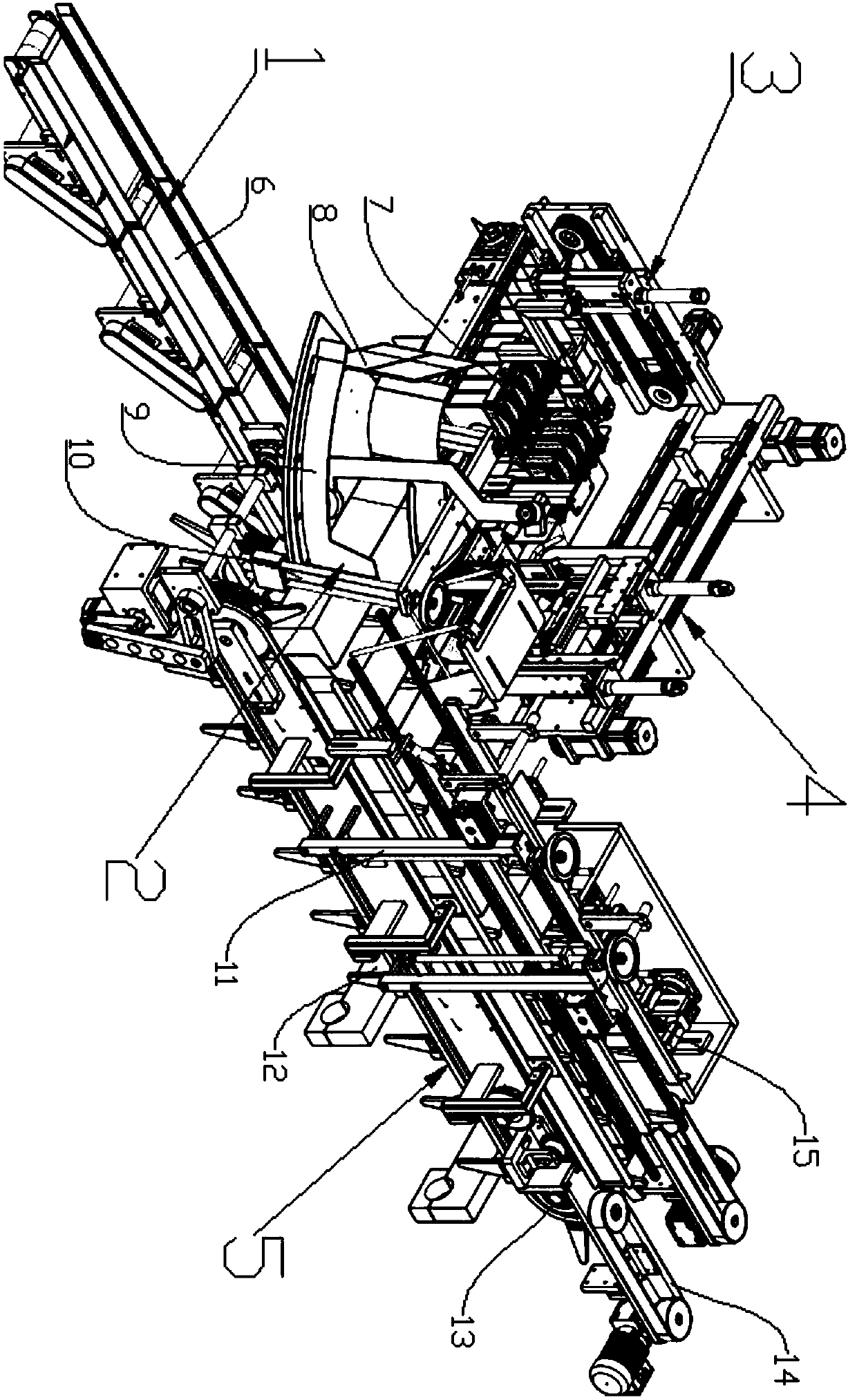

[0019] As in the accompanying drawings figure 1 The multi-material automatic collection and boxing system shown is a multi-material automatic collection and boxing system and its packaging process. The boxing system includes a feeding and conveying unit 1, a box blank opening unit 2, a collecting and sorting unit 3, and a boxing unit 4 With the box chain unit 5, the feeding conveying unit 1 is connected by several conveyor belts 6. The feeding conveying unit 1 is provided with a collection unit 3 and a box loading unit 4 side by side. The collection unit 3 includes a cargo collection system 7 and The unloading pusher, the unloading pusher is set perpendicular to the feeding conveying unit 1, the cartoning unit 4 includes the cartoning pusher and material care, the cartoning pusher is perpendicular to the box blank opening unit 2, the box blank opening unit 2 and the feeding conveying unit 1 Arranged in parallel, the box blank opening unit 2 includes a box blank storage bin 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com