Rough fodder cutting device for cattle breeding

A cutting device, roughage technology, applied in feed, application, metal processing and other directions, can solve the problems of slow cutting speed, poor applicability, immovability, etc., and achieve the effect of strong stability, convenient movement and easy feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

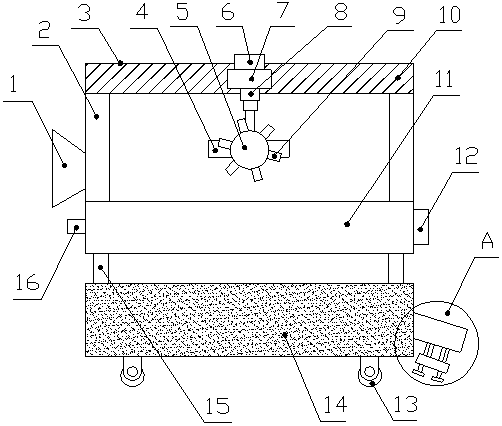

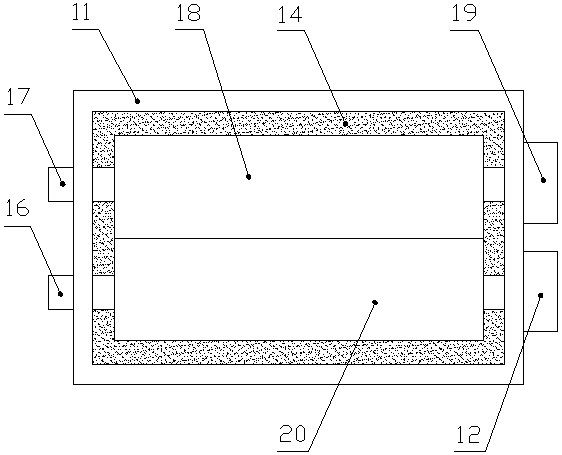

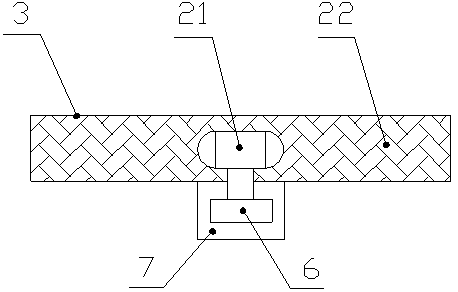

[0019] Such as Figure 1-6 As shown, a roughage cutting device for cattle breeding, which includes a receiving box 14, the left and right sides of the lower end of the receiving box 14 are equipped with walking wheels 13, and the lower right side of the receiving box 14 is connected with an outlet Material pipe 24, a groove 23 is provided in the middle of the inner wall on the upper side of the discharge pipe 24, and a plugboard 25 is inserted into the groove 23, and the lower end of the plugboard 25 passes through the lower side of the discharge pipe 24 The through hole of the wall is fixedly connected with a connecting plate 26, and the connecting plate 26 is connected with the discharge pipe 24 through a bolt 27, and the left and right sides of the upper end of the receiving box 14 are fixedly connected with supporting columns 15, and the supporting The upper end of the column 15 is fixedly connected with the working frame 11, the middle part of the left side of the working...

Embodiment 2

[0022] Such as Figure 1-6 As shown, a roughage cutting device for cattle breeding, which includes a receiving box 14, the left and right sides of the lower end of the receiving box 14 are equipped with walking wheels 13, and the lower right side of the receiving box 14 is connected with an outlet Material pipe 24, a groove 23 is provided in the middle of the inner wall on the upper side of the discharge pipe 24, and a plugboard 25 is inserted into the groove 23, and the lower end of the plugboard 25 passes through the lower side of the discharge pipe 24 The through hole of the wall is fixedly connected with a connecting plate 26, and the connecting plate 26 is connected with the discharge pipe 24 through a bolt 27, and the left and right sides of the upper end of the receiving box 14 are fixedly connected with supporting columns 15, and the supporting The upper end of the column 15 is fixedly connected with the working frame 11, the middle part of the left side of the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com