Ammonia containing tail gas treatment device in dry ammonium section of alkali industry and treatment method thereof

A technology of tail gas treatment and alkali-dried ammonium, which is applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of increasing the recovery and utilization rate of ammonia, achieve good absorption effect, avoid waste liquid generation, and reduce emission indicators Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

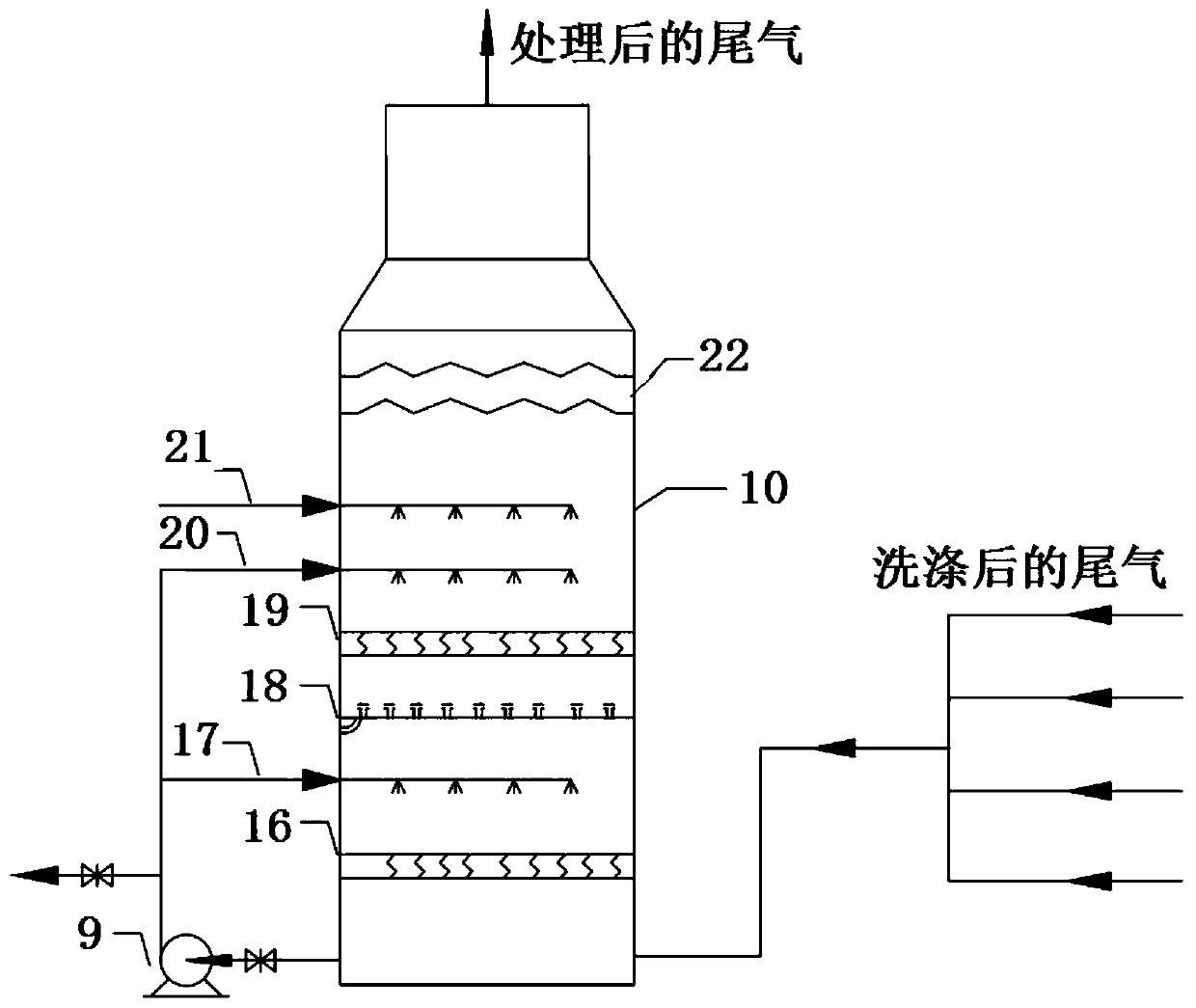

[0040] A device for treating ammonia-containing tail gas in the dry ammonium section of the alkali industry, comprising an ammonia-based desulfurization device and a combined-alkali dry ammonium-containing tail gas dust removal and absorption device; the ammonia-based desulfurization device is connected to the combined-alkali dry ammonium ammonia-containing tail gas dust removal and absorption device . Wherein, the ammonia desulfurization device comprises a desulfurization tower 1, an oxidation tank 8, a flue gas absorption circulation pump 2, a concentration circulation pump 7 and an ammonium sulfate centrifuge 6; The centrifuge 6 is connected, and the desulfurization tower 1 forms a circulation connection with the oxidation tank 8 through the flue gas absorption circulation pump 2 . The dry ammonium-containing ammonia tail gas dedusting and absorption device of the combined alkali includes an ammonia tail gas absorption tower 10, a bag dust collector 11, a tail gas scrubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com