Paper making sewage treatment and reuse process

A technology of papermaking sewage and process, which is applied in the field of papermaking wastewater treatment and reuse process, can solve the problems of complex steps, difficult operation, high total nitrogen content of wastewater, etc., and achieve the effect of simple steps, convenient operation and short treatment cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

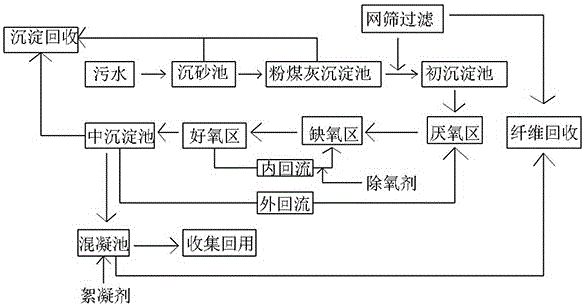

[0022] Embodiment 1: as attached figure 1 As shown, a papermaking wastewater treatment and reuse process, including the adjustment of the initial sedimentation system, the sedimentation system in AAO and the coagulation reaction recycling system arranged in sequence,

[0023] The adjusting primary sedimentation system includes a grit chamber for sedimentation to remove suspended solids and impurities with a larger specific gravity, a fly ash sedimentation tank for adsorption and removal of smaller impurity particles in the wastewater, and The primary sedimentation tank used to collect waste water after the first sedimentation and adsorption treatment. The pipeline that extracts the supernatant from the fly ash sedimentation tank to the primary sedimentation tank is equipped with a filter for collecting wood particles larger than 0.2mm. Fiber filter screen, the filter screen is a 60-mesh inclined screen, the angle between the screen and the direction of waste water flow is 30 °...

Embodiment 2

[0040] Embodiment 2: as attached figure 1 As shown, a papermaking wastewater treatment and reuse process, including the adjustment of the initial sedimentation system, the sedimentation system in AAO and the coagulation reaction recycling system arranged in sequence,

[0041] The adjusting primary sedimentation system includes a grit chamber for sedimentation to remove suspended solids and impurities with a larger specific gravity, a fly ash sedimentation tank for adsorption and removal of smaller impurity particles in the wastewater, and The primary sedimentation tank used to collect waste water after the first sedimentation and adsorption treatment. The pipeline that extracts the supernatant from the fly ash sedimentation tank to the primary sedimentation tank is equipped with a filter for collecting wood particles larger than 0.2mm. Fiber filter screen, the filter screen is a 60-mesh inclined screen, the angle between the screen and the direction of waste water flow is 30 °...

Embodiment 3

[0058] Embodiment 3: as attached figure 1 As shown, a papermaking wastewater treatment and reuse process, including the adjustment of the initial sedimentation system, the sedimentation system in AAO and the coagulation reaction recycling system arranged in sequence,

[0059] The adjusting primary sedimentation system includes a grit chamber for sedimentation to remove suspended solids and impurities with a larger specific gravity, a fly ash sedimentation tank for adsorption and removal of smaller impurity particles in the wastewater, and The primary sedimentation tank used to collect waste water after the first sedimentation and adsorption treatment. The pipeline that extracts the supernatant from the fly ash sedimentation tank to the primary sedimentation tank is equipped with a filter for collecting wood particles larger than 0.2mm. Fiber filter screen, the filter screen is a 60-mesh inclined screen, the angle between the screen and the direction of waste water flow is 30 °...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com