Structure for sealing cavity hole

A technology of sealing structure and cavity, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as difficult repair, poor reliability, and affecting the life of seals, so as to prevent pollution, reliable sealing, and affect performance and life. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be described in detail by taking the embodiment of screw hole hermetic packaging as an operation case in conjunction with the accompanying drawings. It is worth noting that the given embodiments can not be interpreted as limiting the protection scope of the present invention, and some non-essential improvements and adjustments made by those skilled in the art according to the content of the present invention above should still belong to the protection of the present invention. scope.

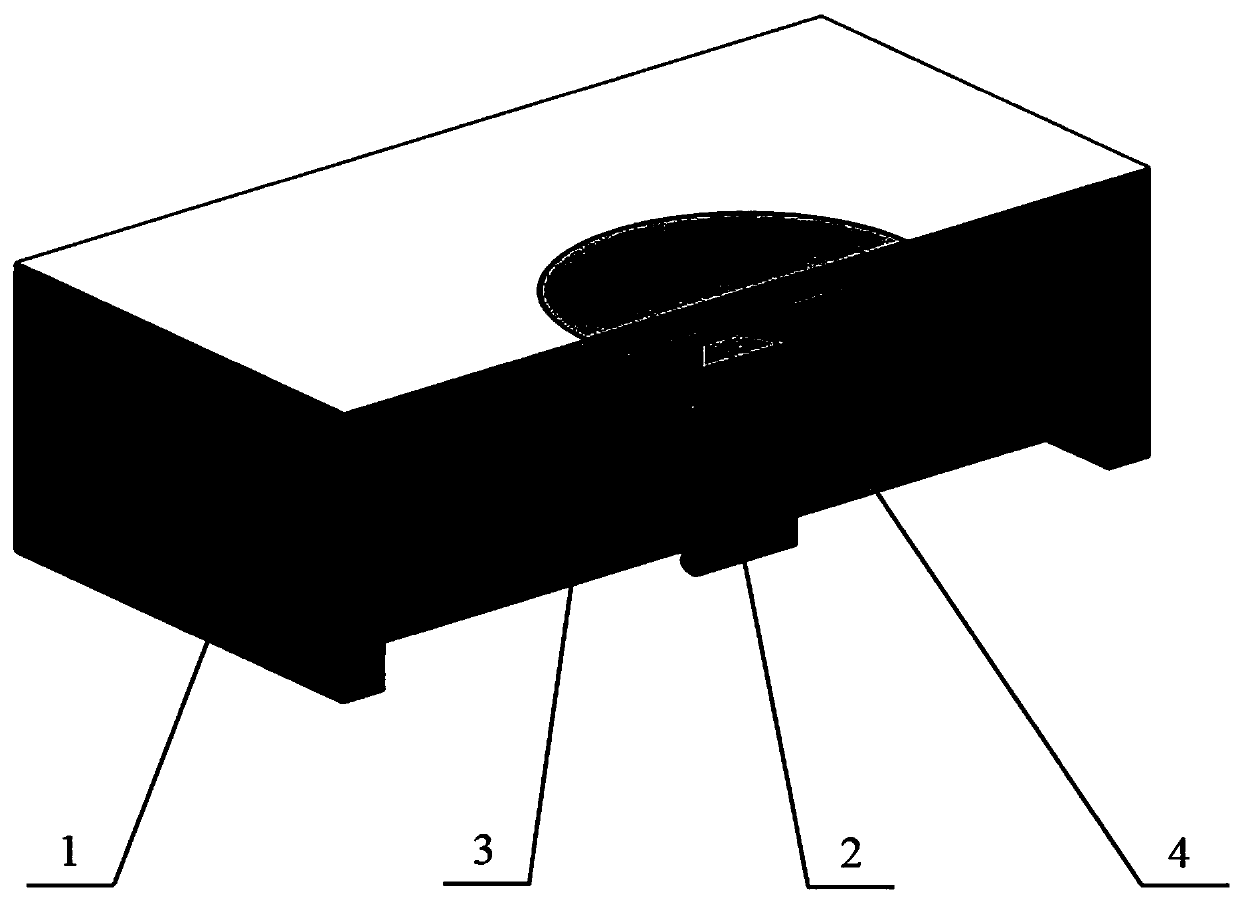

[0021] like figure 1 As shown, the countersunk screw (3) connects the cavity (1) with other components, and since the cavity (1) is required to be airtight, the countersunk screw hole (102) needs to be sealed.

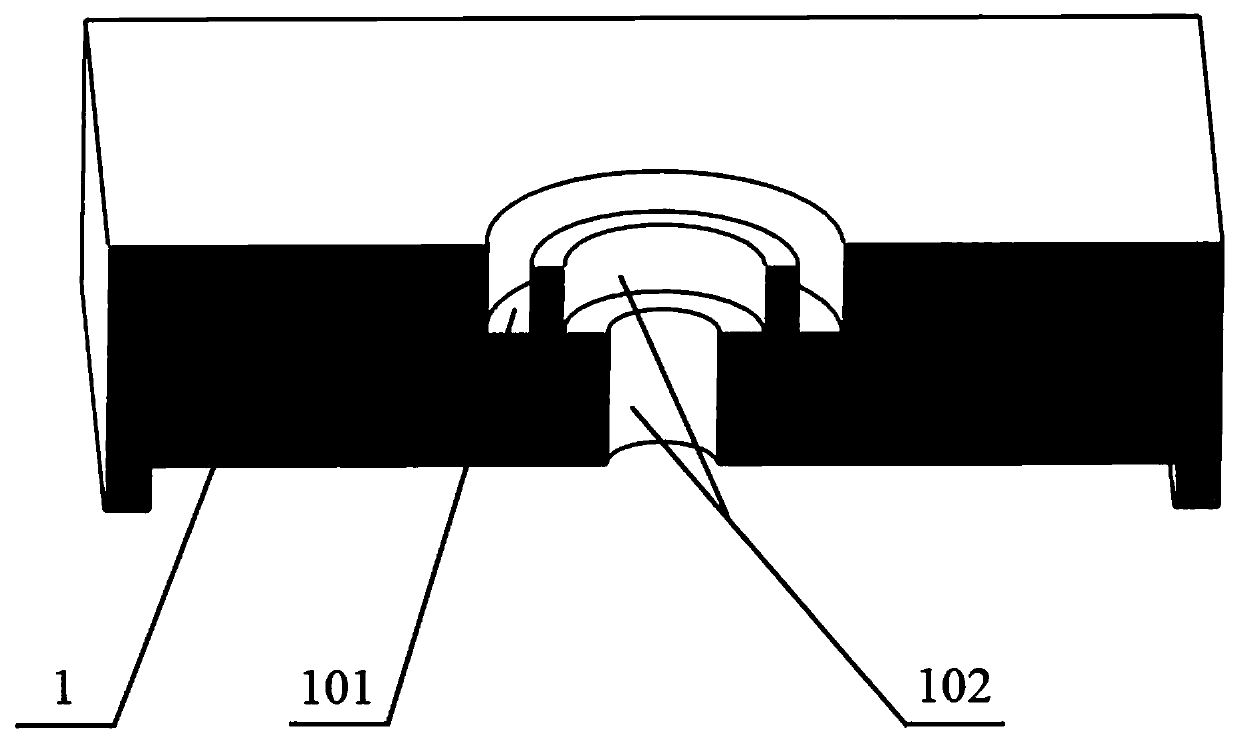

[0022] First process the ring groove (101) outside the countersunk screw hole (102) of the cavity (1), such as image 3 shown. The depth of the ring groove (101) is greater than the height of the shape memory alloy ring (3), and the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com