Pipe column and method for rapid production recovering after gas well killing

A string and fast technology, applied in the direction of wellbore/well components, drill pipe, casing, etc., can solve the problems of unsatisfactory on-site production resumption, large coiled tubing run-in requirements, and many run-in procedures, etc., to achieve Improve the liquid-carrying capacity, restore gas well productivity, and reduce the effect of bottom-hole liquid accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

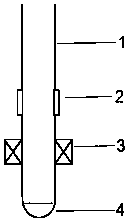

[0023] In order to overcome the need for coiled tubing operation to induce jetting and drainage after on-site well killing, it is easy to be limited by the organization of coiled tubing equipment, and after fracturing, there are many drilling and drilling procedures, with a long cycle, and the effect of on-site resumption of production is not ideal. Coiled tubing is required to run in, which affects the production capacity of gas wells. The present invention provides such figure 1 Shown is a pipe string and method for rapid resumption of production after gas well killing. The present invention artificially creates a pipe string with lower pressure and smaller diameter than the wellbore by running the pipe string for rapid production resumption after the gas well is killed. The flow channel is used to speed up the upward and backward flow rate of gas in the well, improve its liquid carrying capacity, reduce bottom-hole liquid accumulation, reduce bottom-hole back pressure, and m...

Embodiment 2

[0028] On the basis of Embodiment 1, in this embodiment, the tubing 1 is a small-diameter tubing, and the small-diameter tubing is a tubing whose diameter is smaller than that of the original tubing in the kill.

[0029] The sliding sleeve 2 is an openable sliding sleeve, and the equivalent diameter of the nozzle of the sliding sleeve 2 is small, and the upper limit is that the amount of water discharged from the annulus above the packer 3 is sufficient to be carried to the wellhead by the gas volume of the wellbore.

[0030] The packer 3 is a compression packer. The state of the packer 3 can be fixed liner hanging, lifting or rotating string setting and lifting or rotating string unsealing.

[0031] The well-entering state of the plug 4 is closed.

[0032] A method for quickly resuming production after a gas well is killed, the specific steps are:

[0033] Step 1: killing the well, setting up the layered fracturing string,

[0034] Step 2: Run the tubing string for rapid p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com