Compressor, motor thereof, and rotor balance blocks thereof

A rotor balance and rotor technology, applied in the field of compressors, can solve the problems of low utilization rate of cooling oil return channel, rise in stator temperature, slow cooling oil return speed, etc., to ensure lubrication effect and operation reliability, and increase return speed , the effect of speeding up the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

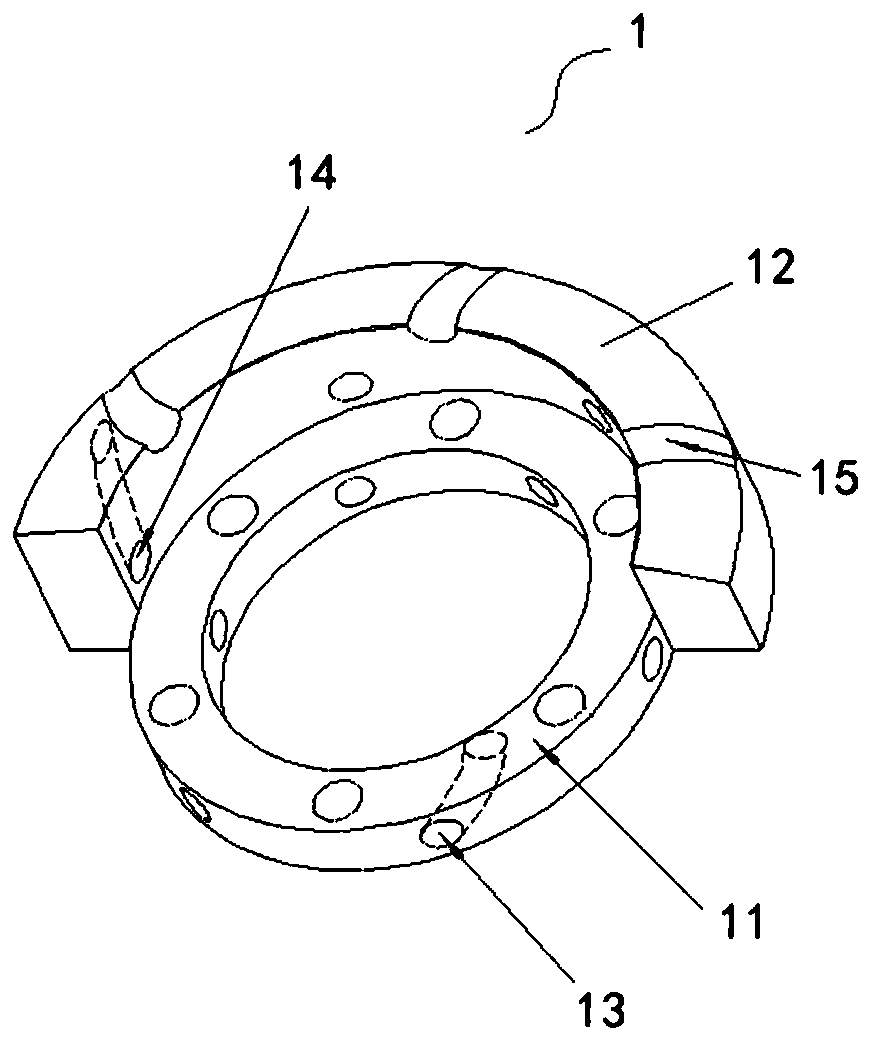

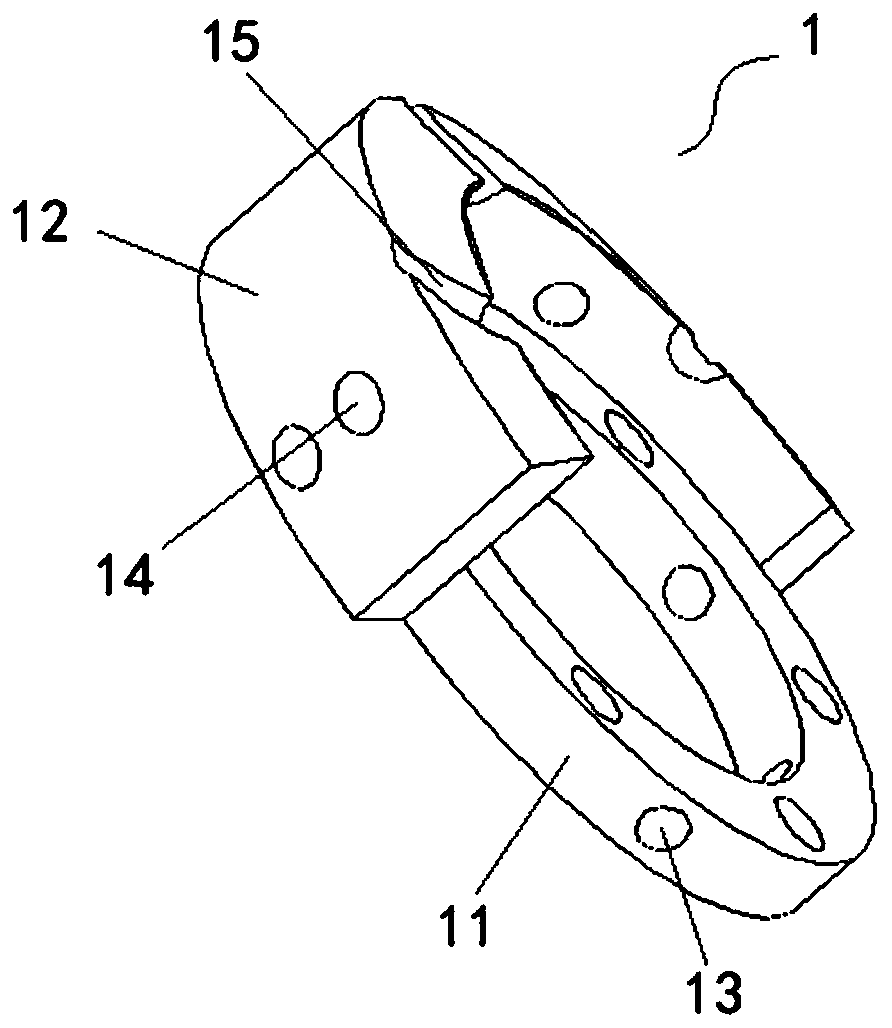

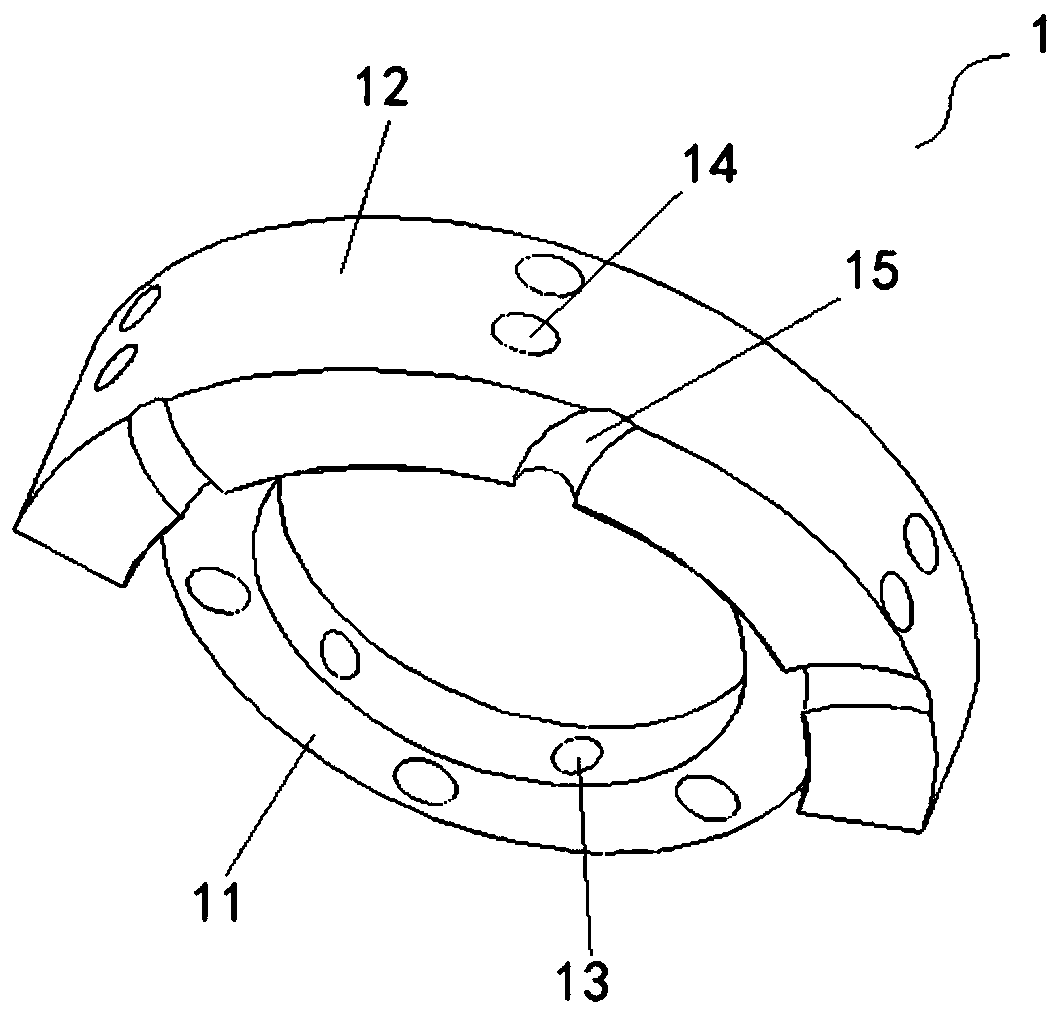

[0039] Please refer to Figure 1-Figure 3 , Figure 1-Figure 3 It is a structural diagram of a specific embodiment of the rotor balance weight provided by the present invention, wherein the direction indicated by the arrow is the communication direction of the cooling oil circulation path 6 .

[0040] In a specific embodiment, the rotor balance weight 1 provided by the present invention is used for a motor, specifically a balance weight structure arranged at both ends of the rotor assembly 3, the rotor balance weight 1 includes a bottom plate 11 and a boss 12, wherein , the bottom plate 11 is provided with a mounting hole and is fixedly connected with the rotor assembly 3 through a rivet passing through the mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com