Ultrathin isothermal plate and method for preparing same

A vapor chamber, ultra-thin technology, used in electrical equipment structural parts, modification by conduction heat transfer, cooling/ventilation/heating transformation, etc., can solve the problem of thermal conductivity, large span, and overall support of the vapor chamber. and other problems to achieve the effect of improving thermal conductivity, improving thermal conductivity, and improving reflow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

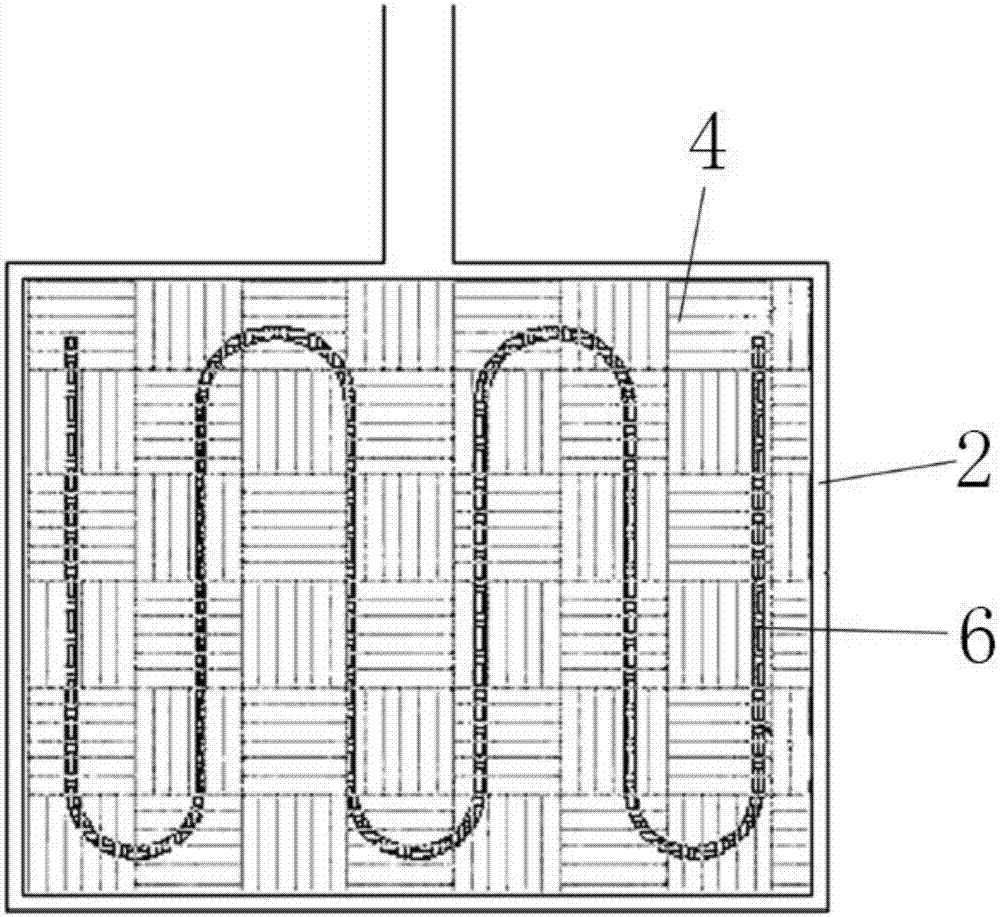

[0028] This embodiment discloses a method for preparing an ultra-thin vapor chamber, which includes the following steps,

[0029] (1) Take the first shell and the second shell of the flat structure, and sinter the capillary liquid-absorbing core on the above-mentioned first shell and the second shell; the above-mentioned first shell and the second shell are arranged facing up and down , and the capillary liquid-absorbent cores of both are arranged on the inside of their respective shells;

[0030] (2) The supporting structure is centrally placed between the first casing and the second casing, and the supporting structure is inserted between the capillary liquid-absorbing cores of the first casing and the second casing;

[0031] (3) The first shell and the second shell are welded into a tube sheet structure with a cavity inside, and a seal is reserved on the side of the tube sheet; the above-mentioned supporting structure is centered and covered in the cavity of the tube sheet;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com