Heating plate of belt-type drier

A belt dryer and heating plate technology, used in dryers, heating devices, lighting and heating equipment, etc., can solve the problem that the heating plate affects heat conduction and heat transfer, the internal structure of the heating plate is complex, and the effective utilization rate of heat energy is low, etc. problems, to achieve the effect of improving the drying efficiency of materials, optimizing the drying effect of materials, and high effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing:

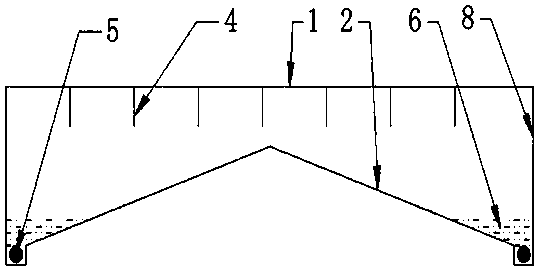

[0045] Such as figure 1 , figure 2 The heating plate of a belt dryer shown includes a top plate 1 , a bottom plate 2 , a side plate 8 , a heating device 5 , a heat conducting strip 4 , and a heat conducting working medium 6 .

[0046] The length of the heating plate of the belt dryer is 8500mm, the width is 1100mm, and the thickness is 118mm.

[0047] The material of the top plate 1, the bottom plate 2 and the side plate 8 is a metal plate.

[0048] The outside of the base plate 2 and the side plate 8 has an insulating layer or does not have an insulating layer.

[0049] The shape of the side plate 8 is L-shaped, the plate surface of the lower end of the side plate 8 is folded in, and the upper end of the side plate 8 is straight.

[0050] The appearance of the bottom plate 2 is V-shaped, and the sharp corner of the V-shaped bottom plate 2 is upward.

[0051] The incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com