Automatic feeding system for semi-flexible cable hot tinning process and automatic feeding method

A technology of automatic feeding and hot-dip tinning, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems of endangering the occupational health of operators, high labor intensity of operators, and rapid volatilization of flux. , to achieve the effect of benefiting workers' occupational health, saving material costs, and being beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

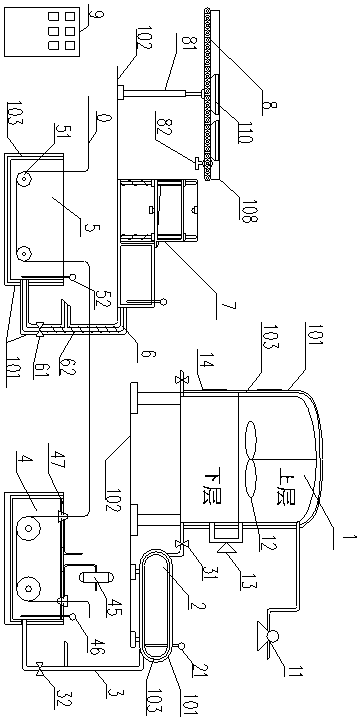

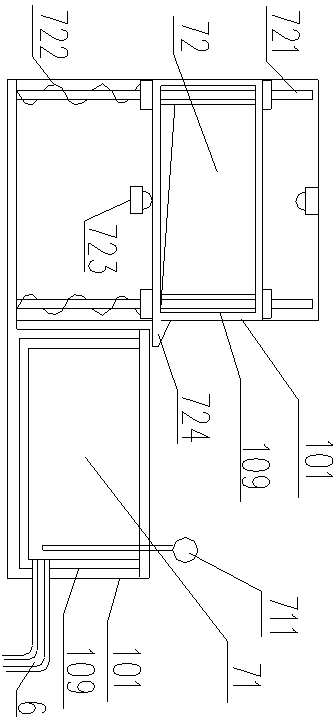

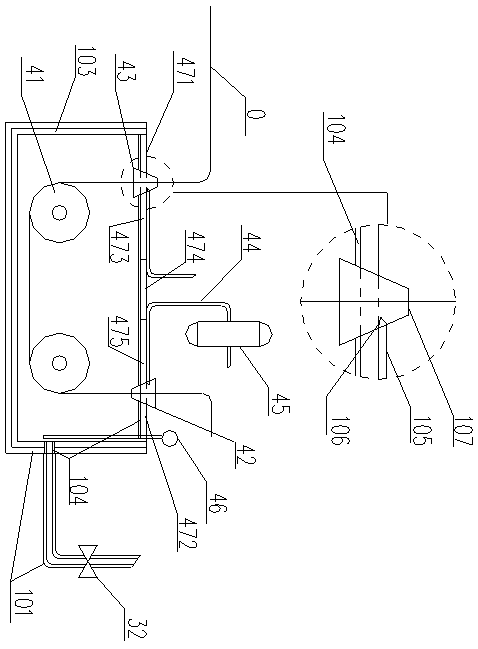

[0026] Such as figure 1As shown, an automatic feeding system for the hot tinning process of semi-flexible cables, including an automatic fluxing system, an automatic tinning system and a temperature control cabinet 9 . The automatic fluxing system includes an automatic liquid pump 11, a liquid storage tank 1, a transfer tank 2, and a flux tank 4 arranged in sequence. The liquid storage tank 1 is divided into upper and lower layers, and each part is connected with a transfusion tube-3. . A control valve 13 is provided on the transfusion pipe 1 between the upper and lower layers of the liquid storage tank 1 , a liquid level indicator 14 is provided on the upper and lower layers of the liquid storage tank 1 , and an insulating layer 101 is provided on the outside of the liquid storage tank 1 . The upper layer of the liquid storage tank 1 is connected with an automatic liquid pump 11, and is provided with a stirring device 12 for stirring materials. The lower layer of the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com