A kind of NdFeB waste impurity removal and extraction device

An extraction device, NdFeB technology, applied in the field of NdFeB waste impurity removal and extraction devices, can solve the problems of rare earth element quality reduction, material waste, low processing efficiency, etc., and achieve the effect of efficient impurity removal and purity assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

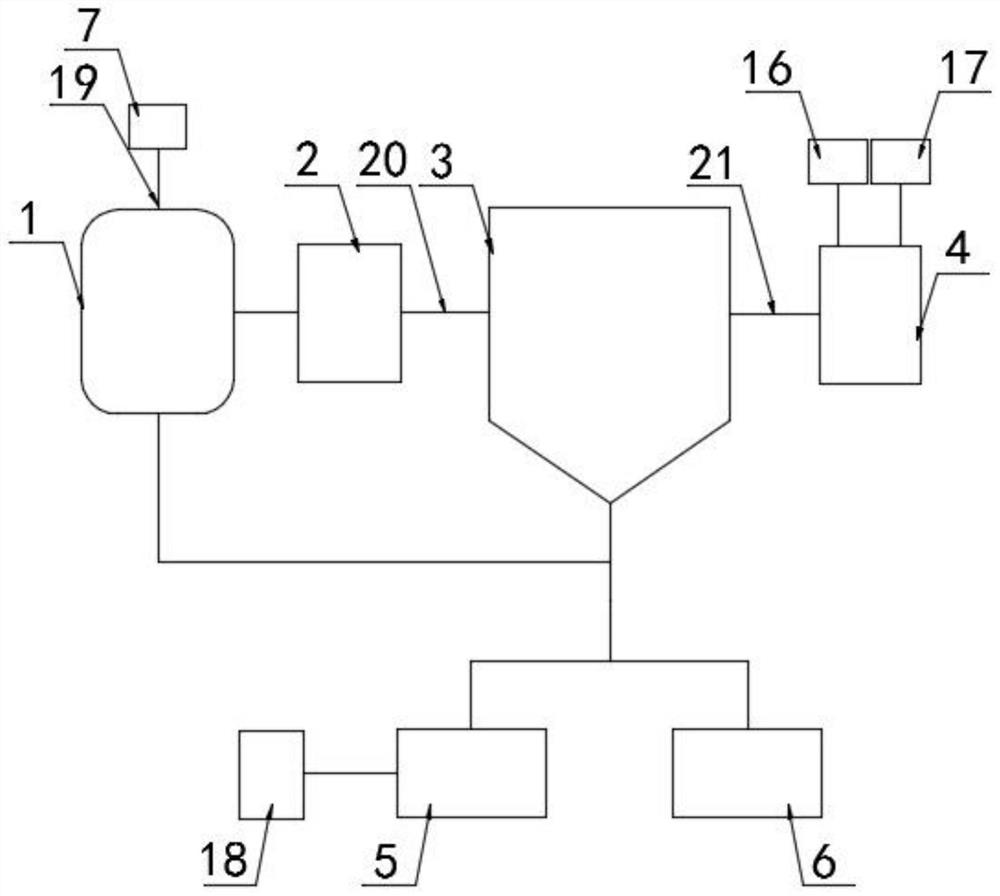

[0027] according to figure 1 The shown a kind of NdFeB waste impurity removal and extraction device includes a reaction pot 1, a filter box 2, an extraction tank 3, a saponification mixing tank 4, a stripping box 5 and a collection box 6, and the filter box 2 is arranged in the reaction pot 1 side, the extraction tank 3 is set on the side of the filter box 2, the saponification mixing tank 4 is set on the side of the extraction tank 3, the stripping tank 5 is set on the front side of the extraction tank 3, and the collection box 6 Arranged on one side of the stripping box 5, the first charging box 7 and the filter box 2 are connected with the reaction pot 1 through the first pipeline 19, the filter box 2 is connected with the extraction tank 3 through the second pipeline 20, and the saponification The mixing tank 4 is connected with the extraction tank 3 through the third pipeline 21, the first pressure pump is provided on the first pipeline 19, the second pipeline 20 and the ...

Embodiment 2

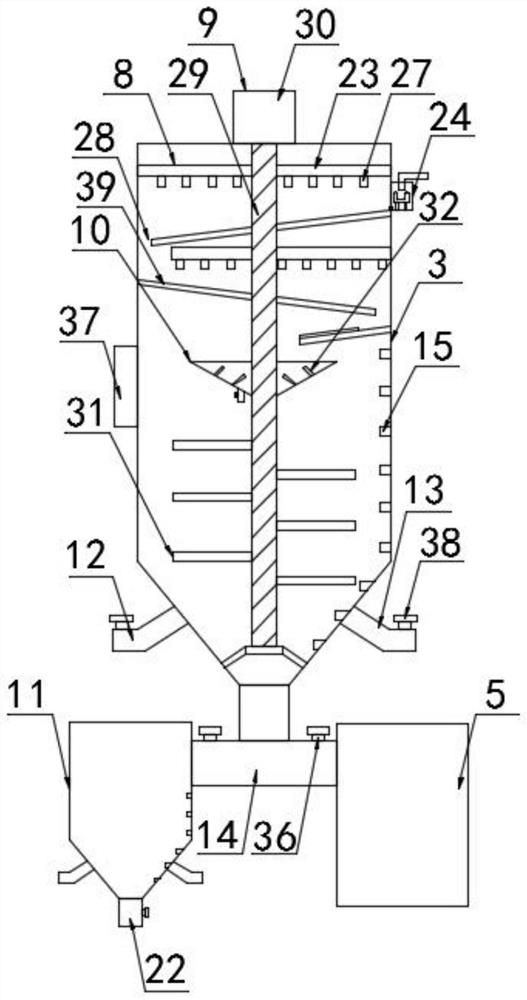

[0030] according to figure 2 In the shown NdFeB waste removal and extraction device, the first outlet pipe 12 and the second outlet pipe 13 are both arranged in a straight line bending shape, and one end of the three-way pipe 14 is connected to the secondary separation tank 11 and The other end is connected with the stripping box 5, and the bottom of the secondary separation tank 11 is provided with a discharge pipe 22, and the discharge pipe 22 is connected with the stripping box 5, so that the mixed rare earth chlorides are conveniently collected and discharged into the stripping box 5 The stripping work is carried out inside, the first outlet pipe 12 is connected with the reaction pot 1, the second outlet pipe 13 is connected with the collection box 6, the first outlet pipe 12 is provided with a second pressure pump, and the first outlet pipe 12 is provided with a second pressure pump. Both the first outlet pipe 12 and the second outlet pipe 13 are provided with a first so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com