Sisal fiber graded broken stone mixed material and preparation method thereof

A technology of sisal fiber and graded crushed stone, which is applied in the field of road engineering materials, can solve the problems of high cost, insufficient strength of graded crushed stone mixture, and insufficient strength, so as to achieve improved service life, good economy and engineering application Value, effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of sisal fiber graded crushed stone mixture is made of the following components by weight percentage:

[0039] Graded gravel: 94.8%;

[0040] Drinking water: 4.7%;

[0041] Sisal fiber: 0.5%.

[0042] The above-mentioned sisal fiber has a length of 1-3 cm, soaked in NaOH solution with a mass concentration of 1% for 15 minutes, washed with clean water and dried.

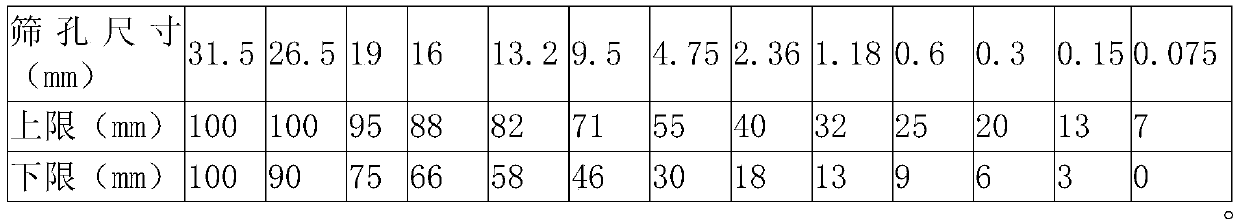

[0043] The above graded crushed stone has the following grades:

[0044]

[0045] The preparation method of sisal fiber graded gravel is realized by the following steps:

[0046] (1) Raw material selection:

[0047] The basalt stone materials used are screened step by step according to the full sieve hole from 0.075-31.5mm, and the aggregates are divided into single-size stones from small to large, and graded crushed stones with the following gradation range are used:

[0048]

[0049] (2) Stir the above graded gravel evenly;

[0050] (3) cutting the sisal fiber into 1-3 cm, soaking it in 1% ...

Embodiment 2

[0058] A kind of sisal fiber graded gravel mixture, is made up of following mass percentage content:

[0059] Graded gravel: 94.7%;

[0060] Drinking water: 4.8%;

[0061] Sisal fiber: 0.5%.

[0062] The above-mentioned sisal fiber has a length of 1-3 cm, soaked in NaOH solution with a mass concentration of 1% for 15 minutes, washed with clean water and dried.

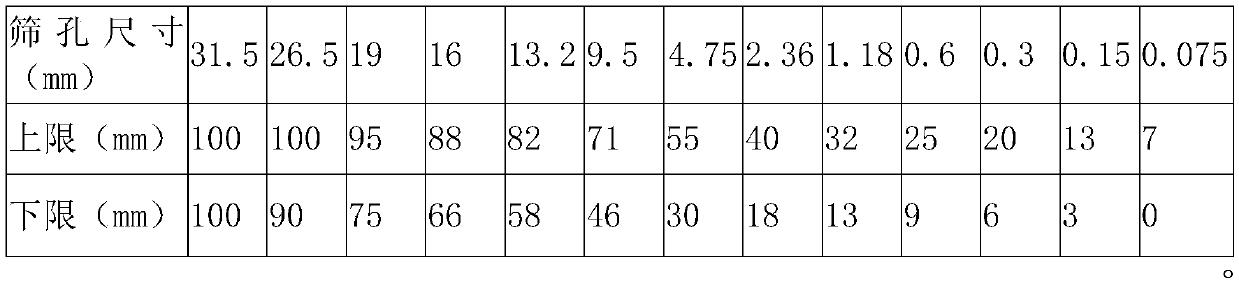

[0063] The above graded crushed stone has the following grades:

[0064]

[0065] The preparation method of the sisal fiber graded crushed stone that the present invention proposes is realized by the following steps:

[0066] (1) Raw material selection:

[0067] The basalt stone materials used are screened step by step according to the full sieve hole from 0.075-31.5mm, and the aggregates are divided into single-size stones from small to large, and graded crushed stones with the following gradation range are used:

[0068]

[0069] (2) Stir the above graded gravel evenly;

[0070] (3) cutting the sisal fibe...

Embodiment 3

[0078] A kind of sisal fiber graded gravel mixture, is made up of following mass percentage content:

[0079] Graded gravel: 93.2%;

[0080] Drinking water: 6%;

[0081] Sisal fiber: 0.8%.

[0082] The above-mentioned sisal fiber has a length of 1-3 cm, soaked in NaOH solution with a mass concentration of 1% for 15 minutes, washed with clean water and dried.

[0083] The above graded crushed stone has the following grades:

[0084]

[0085] The preparation method of the sisal fiber graded crushed stone that the present invention proposes is realized by the following steps:

[0086] (1) Raw material selection:

[0087] The basalt stone materials used are screened step by step according to the full sieve hole from 0.075-31.5mm, and the aggregates are divided into single-size stones from small to large, and graded crushed stones with the following gradation range are used:

[0088]

[0089] (2) Stir the above graded gravel evenly;

[0090] (3) cutting the sisal fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com