Independent adjustable cutting mechanism and intelligent pearl wool dividing machine

A cutting mechanism and adjustable technology, applied in metal processing and other directions, can solve problems such as low product production efficiency, blade cuts, safety accidents, etc., to save time for adjusting tools and solve extremely time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

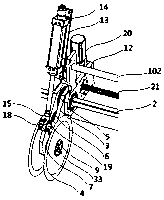

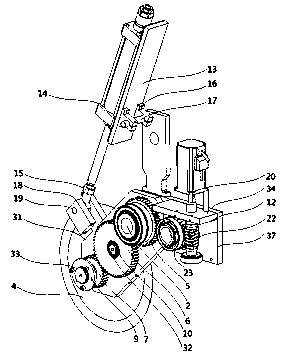

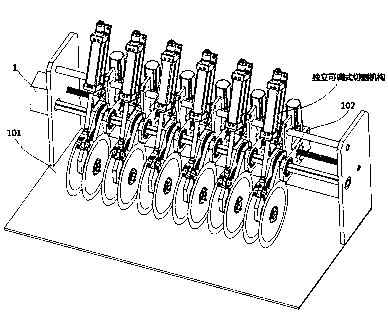

[0020] Such as figure 1 , figure 2 , image 3 As shown, the intelligent pearl cotton cutting equipment includes a seat body 101, a load bearing shaft 102, a drive shaft 2, a screw rod 21 and at least one set of independent adjustable cutting mechanism, and the drive shaft 2 is arranged parallel to the load bearing shaft 102 On the base body 101, the drive shaft 2 is rotationally connected with the base body 101 through a bearing, and the independently adjustable cutting mechanism includes a drive motor 1 connected to the drive shaft 2, and is arranged on the base body through a bearing. The swing arm fixing seat 3 on the drive shaft 2, the transmission device arranged on the swing arm fixing seat 3 and connected with the drive shaft 2, and the transmission device arranged on the outside of the swing arm fixing seat 3 and connected to the transmission The blade 4 connected to the device, the blade 4 can be driven by the rotation of the drive shaft 2, the more the independent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com