Method of lessening vomitoxin in wheat flour

A technology of vomitoxin and wheat flour, applied in food science and other directions, can solve the problems of limited application scope, low efficiency and poor detoxification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

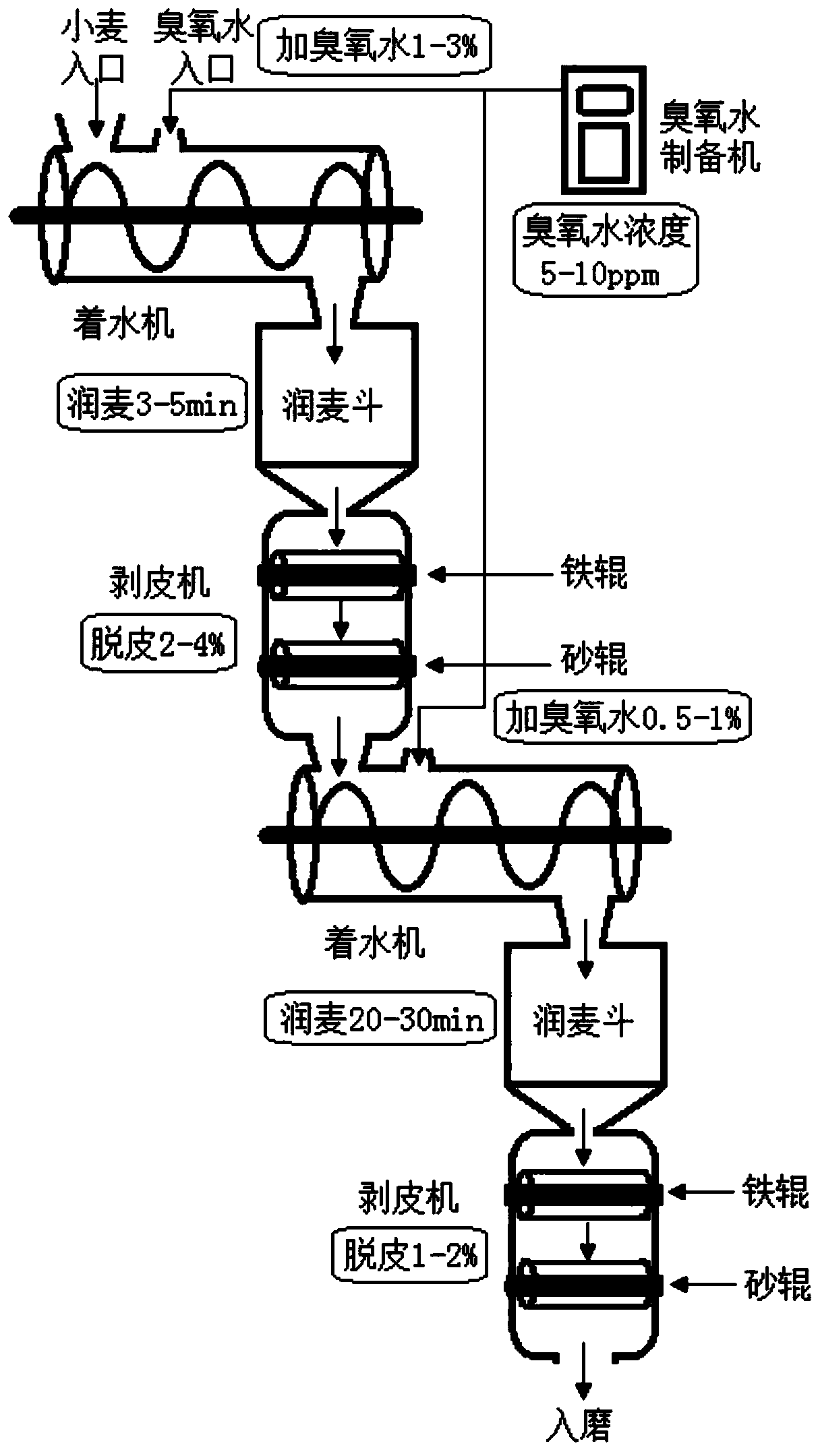

Method used

Image

Examples

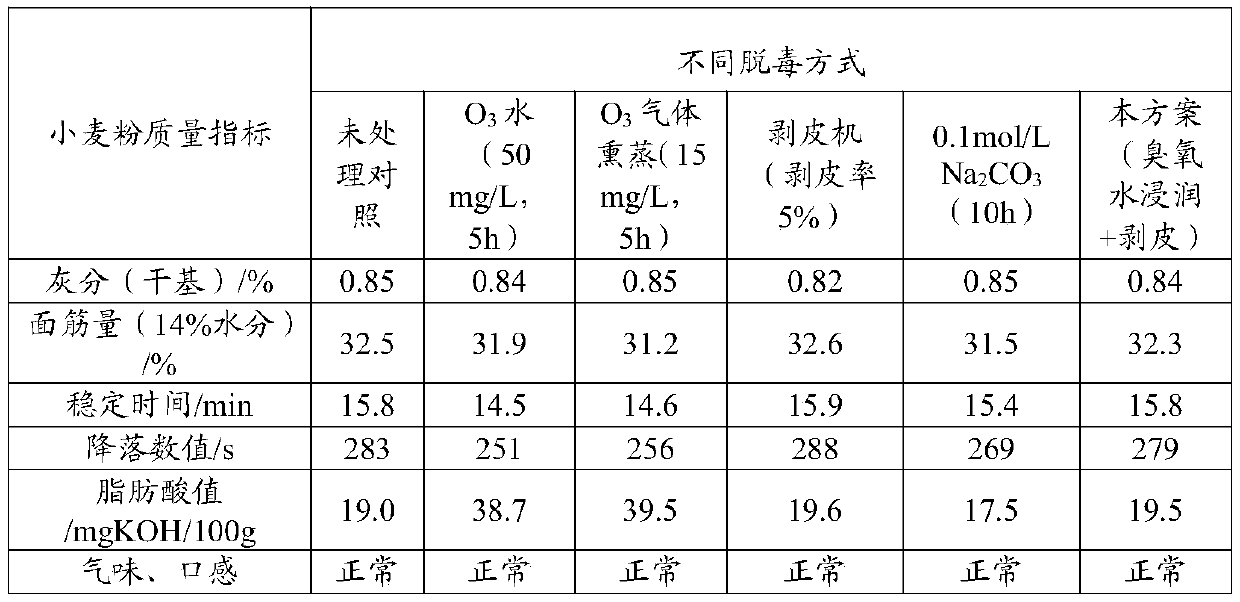

Embodiment 1

[0035] When the DON content in the wheat is 487.68μg / kg, spray the ozone water with a concentration of 6.5mg / L according to the amount of 2.5% of the weight of the wheat. After the ozone water and the wheat are fully mixed for 5 minutes, use the peeling machine for the first peeling. Remove 3.0-3.5% of the bran (3.0-3.5% is the peeling rate, which refers to the percentage of the weight of the removed bran to the total weight of the wheat before peeling), and then evenly spray 0.8% of the weight of the wheat with a concentration of 6.5mg / L ozone water, moisten the wheat for 25 minutes, then peel it twice to remove the remaining 1.5-2.0% of the bran (1.5-2.0% is the peeling rate, which means the weight of the removed bran accounts for the total weight of the wheat before peeling ), and finally into the mill to obtain wheat flour, the content of DON in the wheat flour determined by HPLC method is 29.38μg / kg, no ozone residue. The wheat flour of the same batch of wheat is made by ...

Embodiment 2

[0037] When the DON content in the wheat is 933.21μg / kg, spray the ozone water with a concentration of 9.0mg / L according to the amount of 3.0% of the weight of the wheat. After the ozone water is fully mixed with the wheat for 5 minutes, use the peeling machine for the first peeling. Remove 3.0-3.5% of the bran, and then evenly spray 1.0% of the weight of the wheat with ozone water with a concentration of 6.5mg / L, moisten the wheat for 30 minutes, then peel it twice to remove the remaining 1.5-2.0% of the bran, and finally mill it The wheat flour was obtained by grinding. The content of DON in the wheat flour was determined by HPLC to be 83.93μg / kg, and there was no residual ozone. The wheat flour of the same batch of wheat produced by the traditional milling process (the traditional process is the direct grinding of the wheat after water infiltration), the DON content is as high as 398.27μg / kg. Compared with the quality of wheat flour obtained by traditional flour milling proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com