[0003] It is a deciduous

vine shrub that can grow up to 10 meters. The

cane,

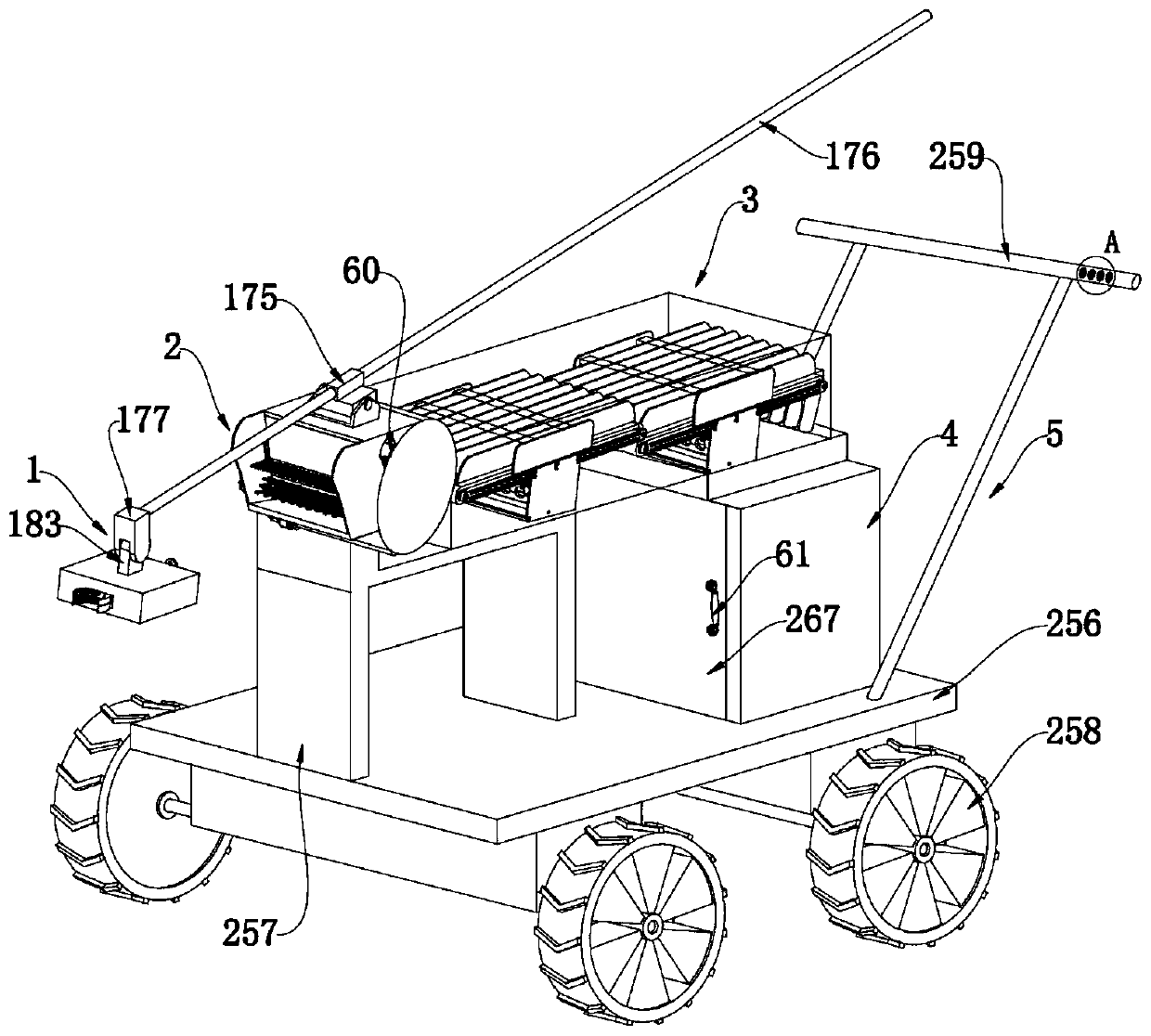

leaf base and fruit are all covered with hard thorns. At present, the fruit of the unicorn is often harvested by

cutting off the fruit

vine manually. In order to avoid damage to the adjacent canes of the fruit and branches and leaves affect the yield in the coming year. When harvesting, the harvesters need to hold scissors and extend into the canes and branches to harvest. Because there are hard thorns on the canes and leaf bases, the harvesters will be hard thorns if they are not careful. Stabbing, the fruit of

Eucheuma chinensis grows in clusters of fruit strings. When harvesting, the harvesters directly harvest the clusters of fruit strings by

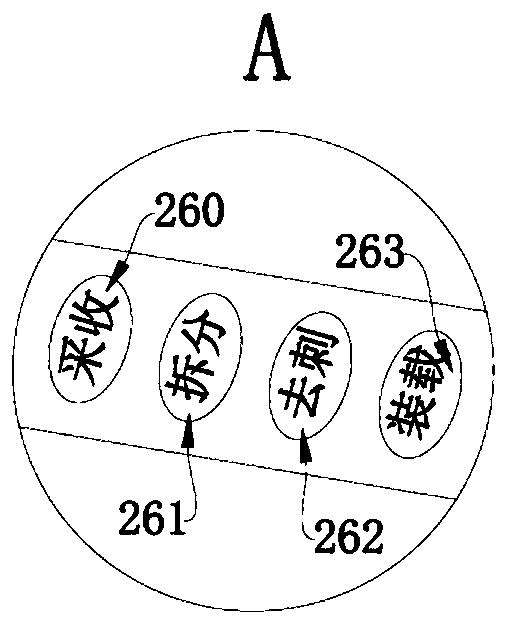

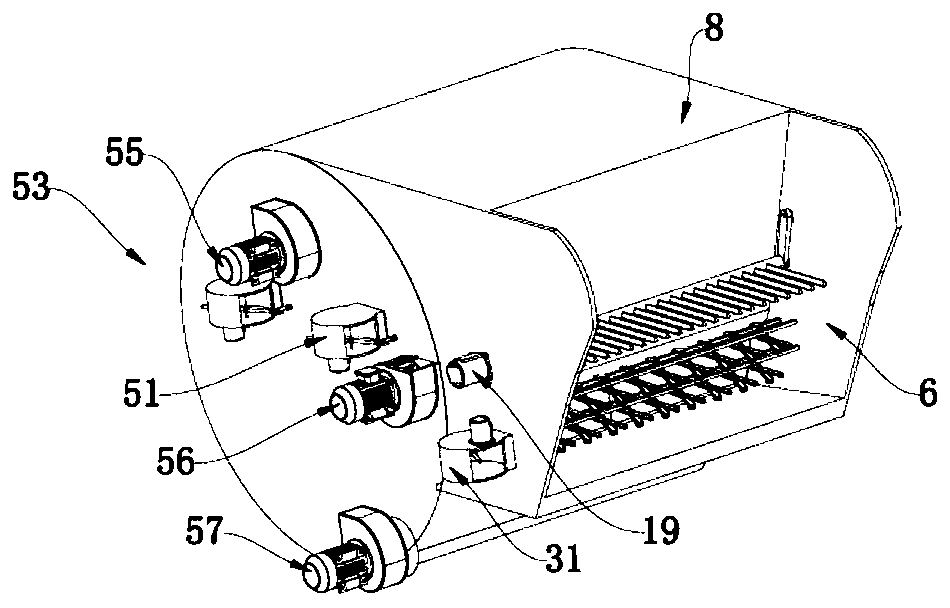

cutting the cane where the fruit strings are located. After harvesting, the fruits on the clusters of fruit strings need to be separated separately The splitting of a single fruit is likely to cause secondary damage to the fruit during the splitting process and the secondary operation will lead to a decrease in labor efficiency. The epidermis is extremely thin, and when the split fruits are stacked together, the fruits will squeeze and collide with each other, and the sharp and hard thorns on the fruit epidermis will pierce the adjacent fruit epidermis, which will affect the storage period of the fruit and reduce the economic value of the fruit. Extruded, collided and punctured each other, the fruit after splitting needs to be de-stabbed on the surface. At present, blades are often used to

cut hard thorns to complete the work of de-stabbing the skin of Kylin fruit. The fruit of Kylin is small and round with thorns. Therefore, the removal of thorns from the fruit surface requires a high level of fine movement of the operator. During the de-stabbing process, the operator needs to keep a close eye on the thorns sticking to the surface of the fruit to

cut and remove the thorns. The eyes of the patient are sore and tired, resulting in inaccurate

cutting angle of the blade or slight slipping will accidentally injure the operator's fingers or the fruit skin. In order to avoid being stabbed by the hard thorns on the cane,

leaf base and fruit, the fruit is harvested and split manually. Protective tools such as gloves need to be worn to carry out corresponding operations when removing thorns and thorns. The use of protective tools prevents harvesters from directly touching the fruit, which greatly affects the operator's operational flexibility, resulting in inaccurate positioning during splitting and thorn removal. Accidentally injuring the fruit itself will affect the storage period of the fruit and reduce the economic value of the fruit. At the same time, the use of protective tools will greatly reduce labor efficiency, and the fruit will be picked up and processed many times during the overall harvesting, splitting and de-thorning process. , put it down, which increases the probability of fruit damage and greatly wastes labor; when harvesting fruits grown at high places, harvesters need to use tools such as escalators to harvest, and harvesters need to carry containers to

climb To carry out on the escalator, the harvesting personnel need to take into account the harvesting height and avoid being stabbed by sharp thorns during the climbing and harvesting process, which will cause the

distraction of the harvesters and affect the safety of the harvesters themselves. During the harvesting process, the harvesters need Constantly move your hands between the

Eucheuma fruit

plant and the container. Repeated reciprocating movements for a long time will easily cause

muscle soreness. When harvesting, one hand holds the scissors and the other hand pinches the

Eucheuma fruit Standing on the escalator and supported by two feet, it is very dangerous and easy to slip off the escalator without safety protection. The container will hinder the climbing and harvesting of harvesters and increase the

risk factor of harvesters. During the first climbing harvest, only the mature fruits within the reach of the harvester's arm can be harvested. Therefore, the harvester needs to keep moving the escalator up and down, which wastes time and reduces the harvesting efficiency. In the process of moving the escalator It is unavoidable to knock down the mature Eucheuma fruit and damage the branches and leaves of Eucheuma, and when moving the escalator, the moved position will overlap with the previous position or the moved position will be far away from the previous position, which will not only waste the harvesting time but also miss the ripe fruit Causes waste, the labor cost of harvesting and

processing the unicorn fruit is very high, the work efficiency is extremely low, and it is impossible to realize the

mechanization of the harvesting and

processing of the unicorn fruit, which greatly restricts the development of the unicorn industry

Login to View More

Login to View More  Login to View More

Login to View More