Quartz crystal oscillator cutting method

A technology of quartz crystal and cutting method, which is applied in the direction of impedance network, electrical components, etc., can solve the problems of signal interruption, temperature characteristic curve cannot bypass the resonant mode resonance point, and cannot transmit signals, so as to suppress resonance and reduce coupling vibration , Improve the effect of TC performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with drawings and embodiments.

[0044] One of the objectives of the present invention is achieved by such a technical solution, a method for cutting a quartz crystal oscillator, which comprises the following steps:

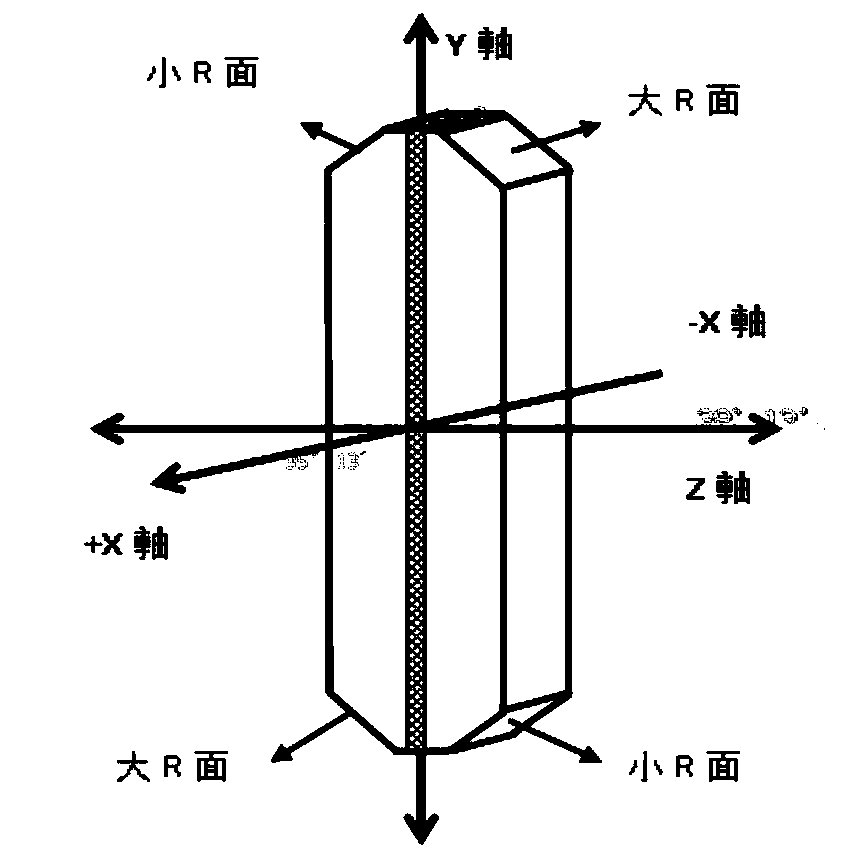

[0045] S1: Obtain the chip axis of the quartz crystal ingot;

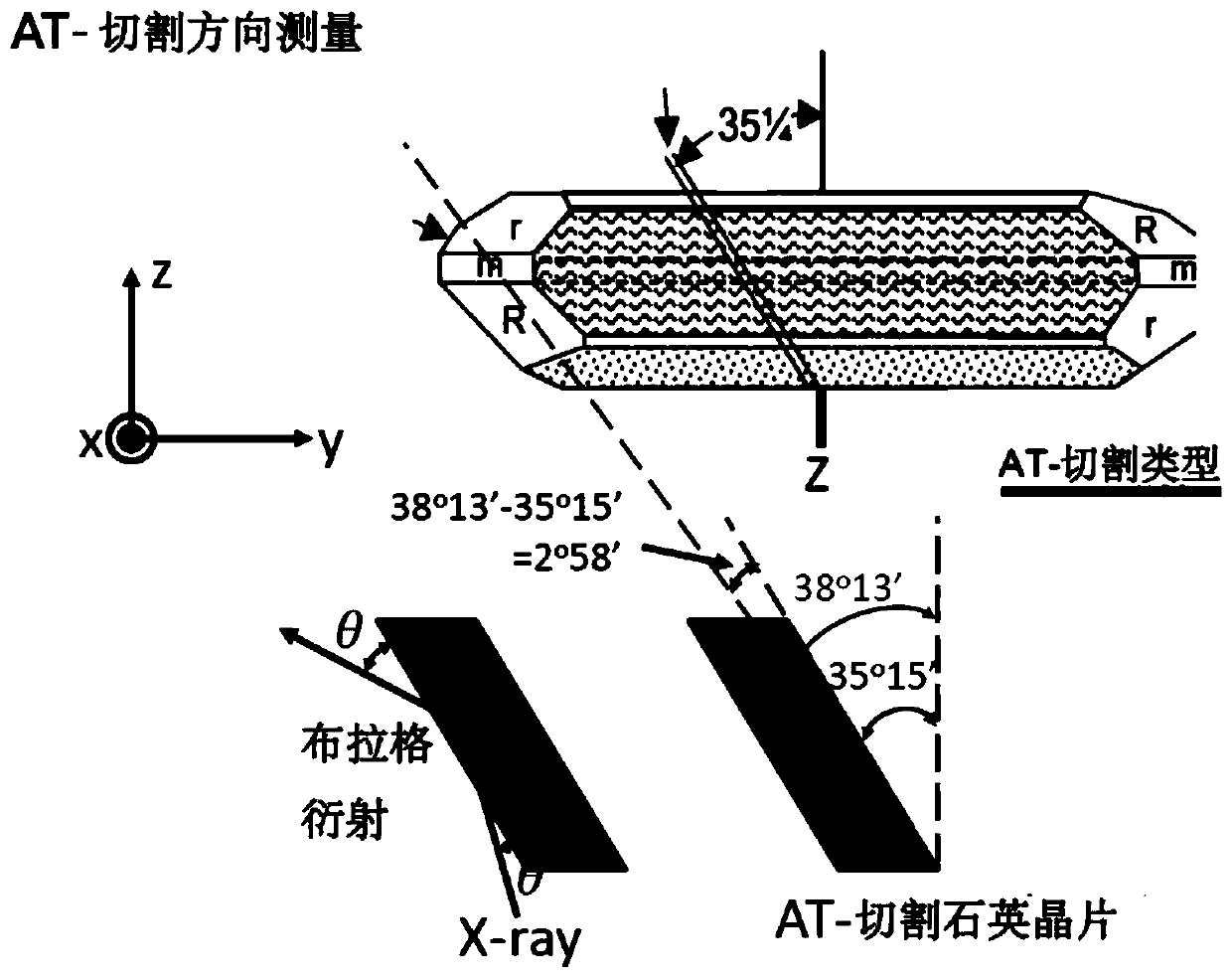

[0046] S2: Measure the angle of the ingot based on the chip axis, and determine the angle according to the measured angle;

[0047] S3: According to the fixed angle, use the AT cutting method to cut the ingot;

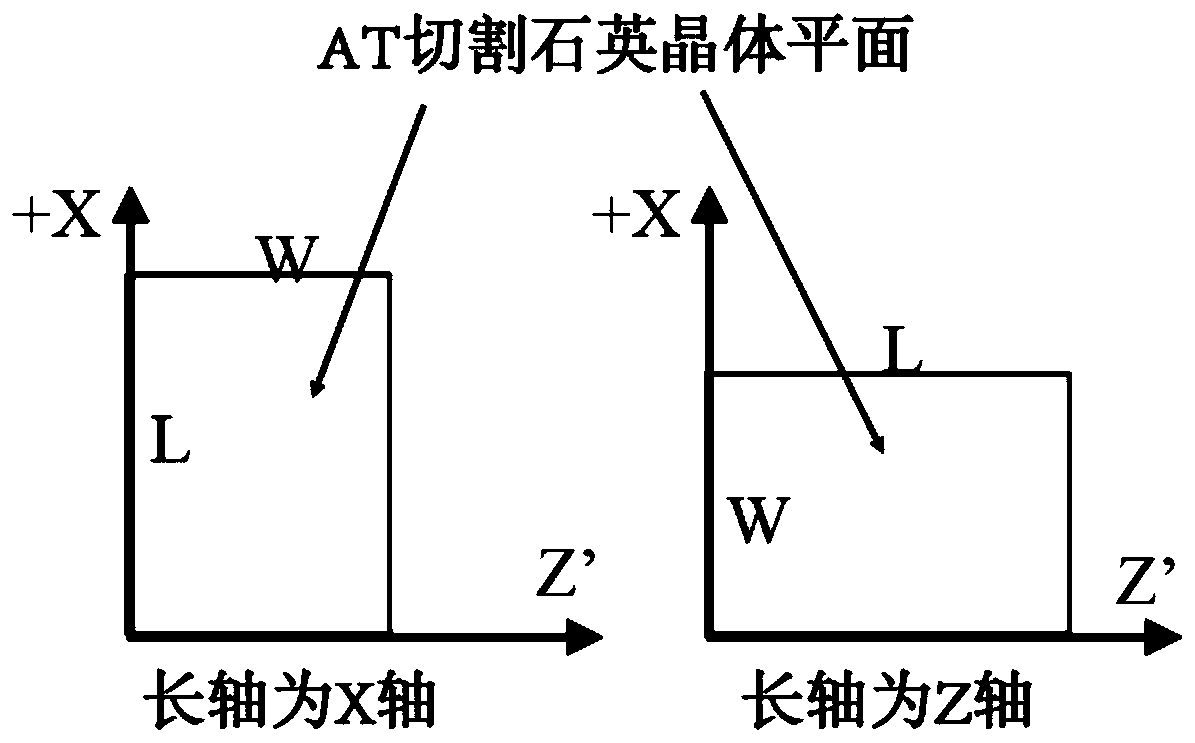

[0048] S4: The large square piece obtained by AT cutting is cut axially with the Z axis as the long side, and the cutting of the quartz crystal ingot is completed.

[0049] Such as figure 1 As shown, in the method of the present invention, the large square sheet obtained by AT cutting is cut axially with the Z axis as the long side, thereby preventing the product use environment from being affected by external condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com