Multi-plane complex load loading test system and test method for spatial structure

A space structure, loading test technology, applied in the direction of using stable torsion to test material strength, using stable bending force to test material strength, using stable tension/pressure to test material strength and other directions, can solve the safety evaluation of space structure damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

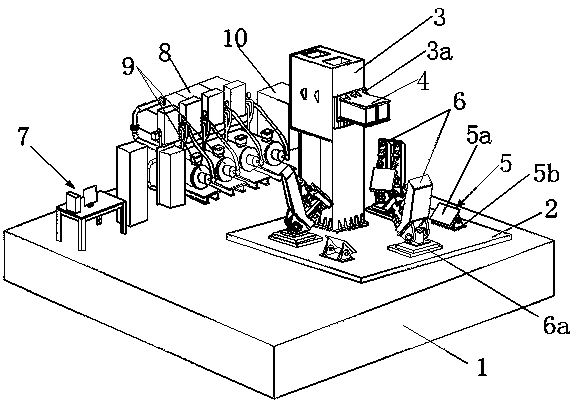

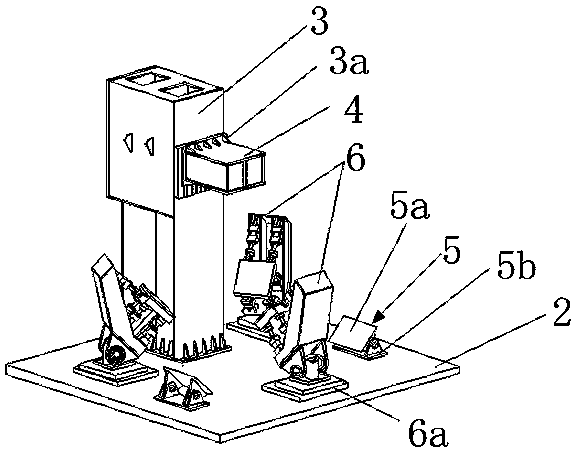

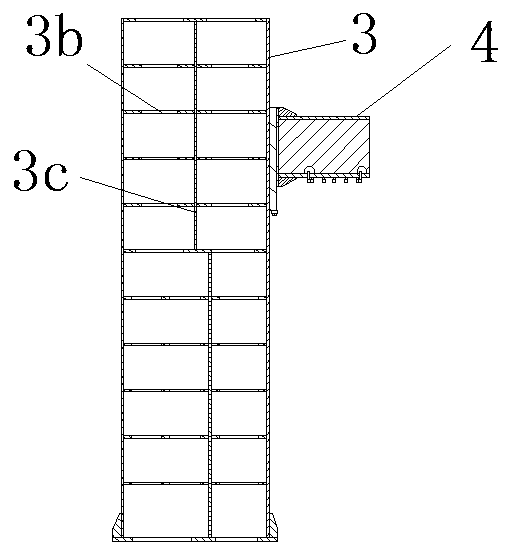

[0044] figure 1 , 2 , 3 shows a layout diagram of a space structure multi-plane complex load loading test system. In the figure, this space structure multi-plane complex load loading test system includes the test system base 2 arranged on the foundation 1, the loading system operating platform 7, the hydraulic oil source 8, the pressurized oil pump 9, the cooling water tank 10 and the electric control system . The test system base 2 is provided with an adjustable reaction force column 3 and a plurality of independent loading units 6 , and one side of the adjustable reaction force column 3 is provided with a cantilever flange fixed end 4 . The position of the cantilever flange fixed end 4 on the adjustable reaction column 3 is adjusted according to the height of the test piece 11 . The base 2 of the test system is an all-roun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com