Static-load bracket preloading construction method of continuous beam

A construction method and preloading technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as high construction costs and affecting construction progress, and achieve the effects of light structure, convenient disassembly and assembly, and safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

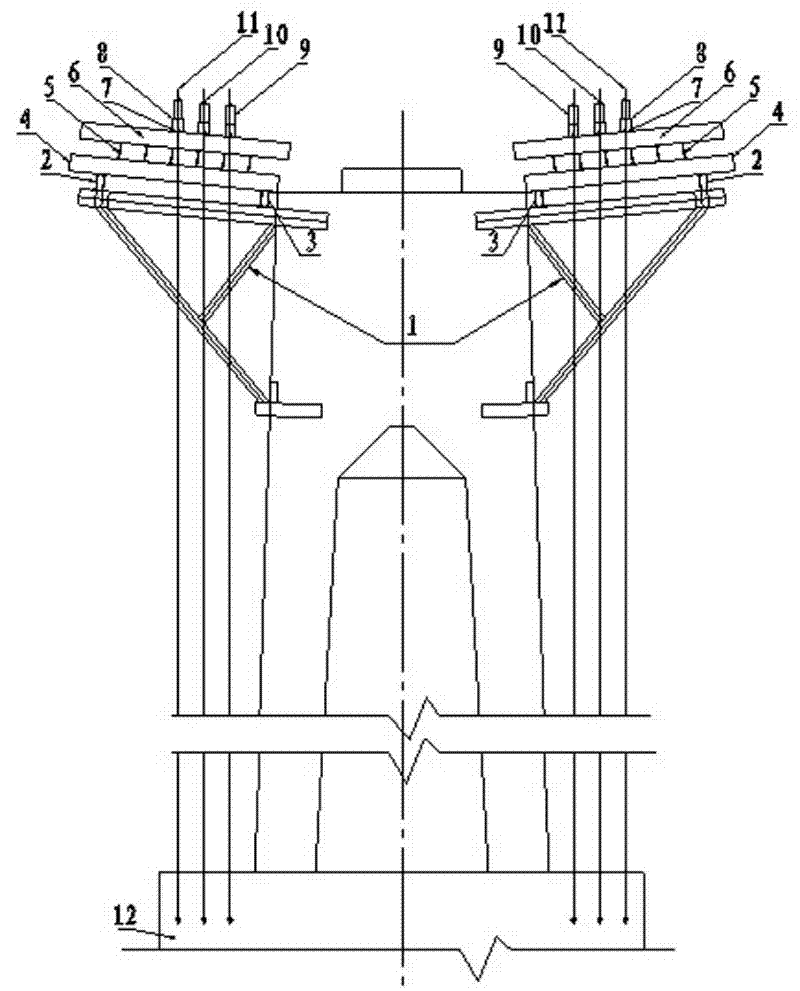

[0021] The specific embodiments of the present invention will be further described with reference to the accompanying drawings.

[0022] 1. Construction method of continuous beam static load preload bracket, the steps are as follows:

[0023] 1. Pre-embedded fine-rolled threaded steel bar

[0024] During the construction of the bearing platform 12, according to the bracket preload anchor point layout diagram in the bearing platform 12 (according to the vertical corresponding position of each part of the continuous beam in the bearing platform, the number of finishing threaded steel bars at the corresponding position of the continuous beam part The maximum tensile force of ×85% finishing threaded steel bar is ≥ 1.2 times the construction load of the continuous beam part, and the finishing threaded steel bar is pre-embedded. When pre-embedding, the anchor plate 7 and the nut are used at the lower part of the finishing threaded steel bar 11 as the Reinforce anchor points. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com