Walking type forklift

A walking type, forklift technology, applied in the direction of lifting devices, etc., can solve the problems of unfavorable handling, stacking goods, high height of electric forklift, complex lifting structure, etc., and achieve the effect of high lifting height, convenient installation, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

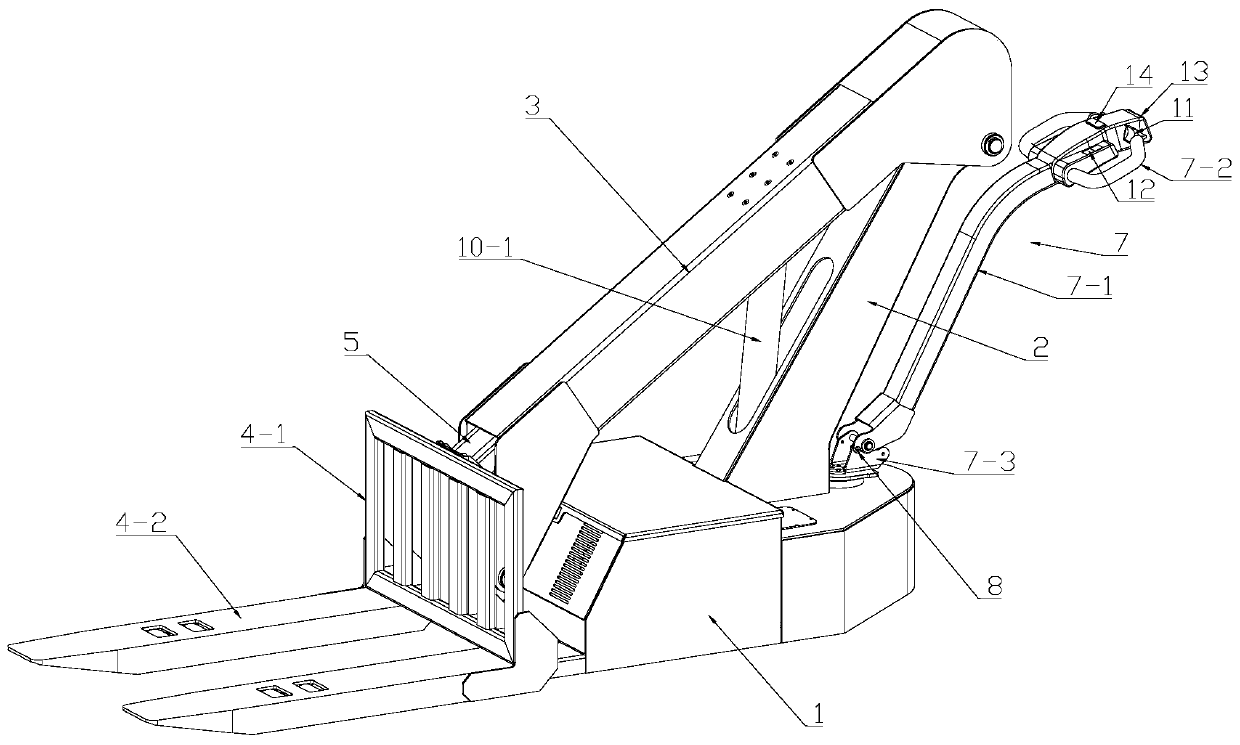

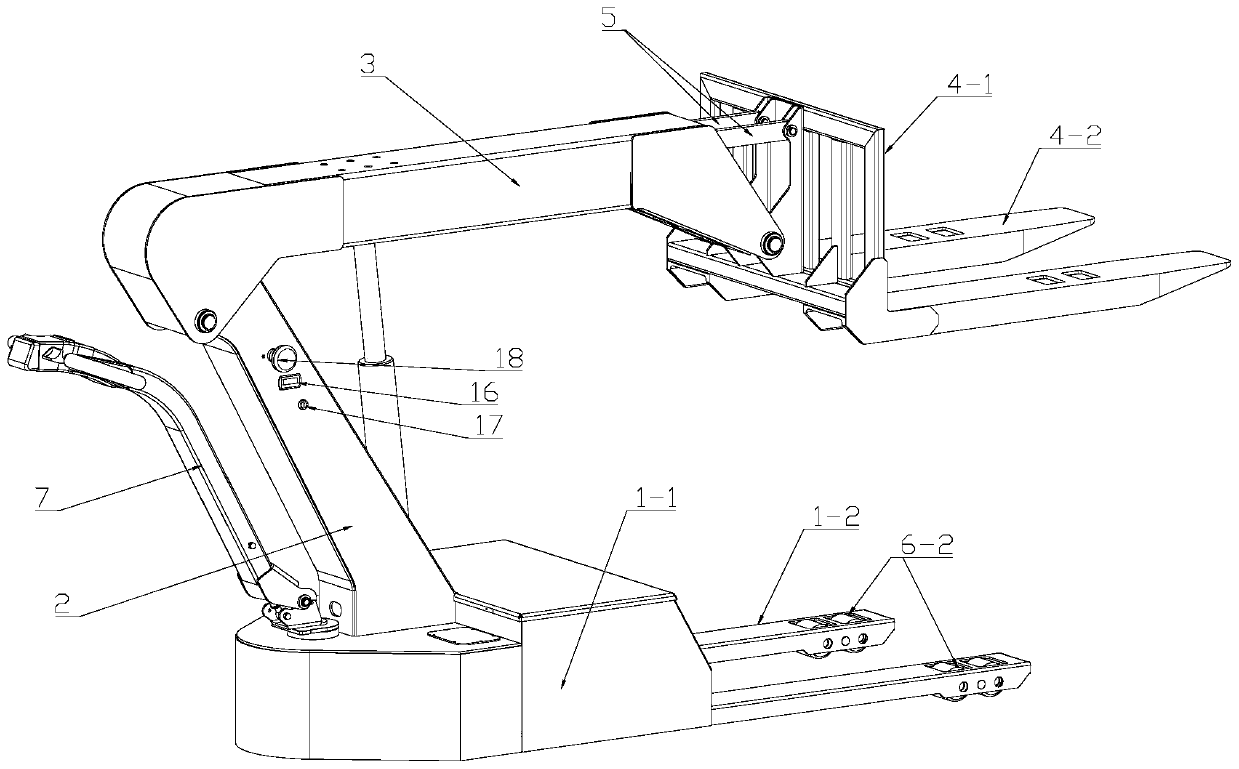

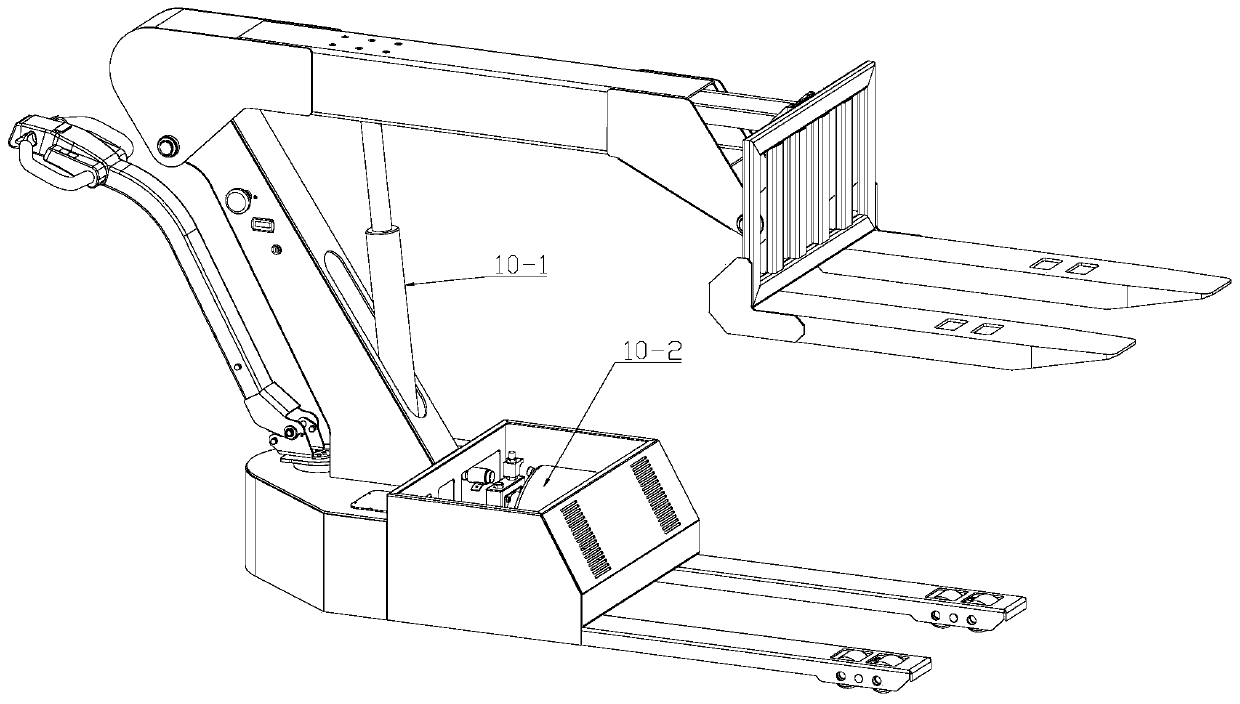

[0032] Example 1, such as Figure 1-7 As shown, a walking type forklift includes a traveling chassis device, a lifting device and an operating device. The traveling chassis device includes a traveling chassis 1 and wheels mounted on the traveling chassis 1, and the wheels drive the traveling chassis 1 to walk. The operating device controls the walking chassis 1 device to travel, and controls the hoisting device to perform lifting. The lifting device includes a support arm 2, a lifting arm 3, a fork device and a lifting drive device. The support arm 2 is tilted backward, the lower end of the support arm 2 is fixed on the walking chassis 1, and the upper end of the support arm 2 is connected to the lifting arm. The rear end of the boom 3 is hinged, the boom 3 extends toward the front of the vehicle, and the lifting drive device drives the boom 3 to rotate around the hinge point to rise or fall, and the front end of the boom 3 has a fork device. The walking chassis 1 has a door-...

Embodiment 2

[0040] Embodiment 2, compared with embodiment 1, the difference is: there is an electromagnetic brake on the rear steering wheel 6-1, and the electromagnetic brake can be deactivated when it is energized, and the rear steering wheel 6-1 is braked, and the handrail tube 7-1 and the handrail The hinge of the seat 7-3 has a position sensor for detecting the position of the handrail tube 7-1, which is used to control the energization of the electromagnetic brake when it is detected that the handrail tube 7-1 is pressed down and swings away from the initial position, and the rear steering wheel 6- 1 brake. The position sensor provided at the hinge of the armrest pipe 7-1 and the armrest seat 7-3 is a proximity switch 15. Specifically, in Figure 8 and 9 It can be seen in the figure that the proximity switch 15 is fixed on the armrest seat 7-3, and the armrest tube 7-1 has an angle iron that cooperates with the proximity switch 15, and the proximity switch 15 detects whether the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com