Integrated DCDC system for hydrogen fuel-cell powered vehicle

A technology of fuel cells and automobiles, which is applied in the direction of battery/battery traction, vehicle components, hydrogen transportation technology, etc. It can solve the problems of unsatisfactory users, increased failure rate, and high cost, so as to reduce the failure rate, reduce ECU parts, The effect of high contribution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

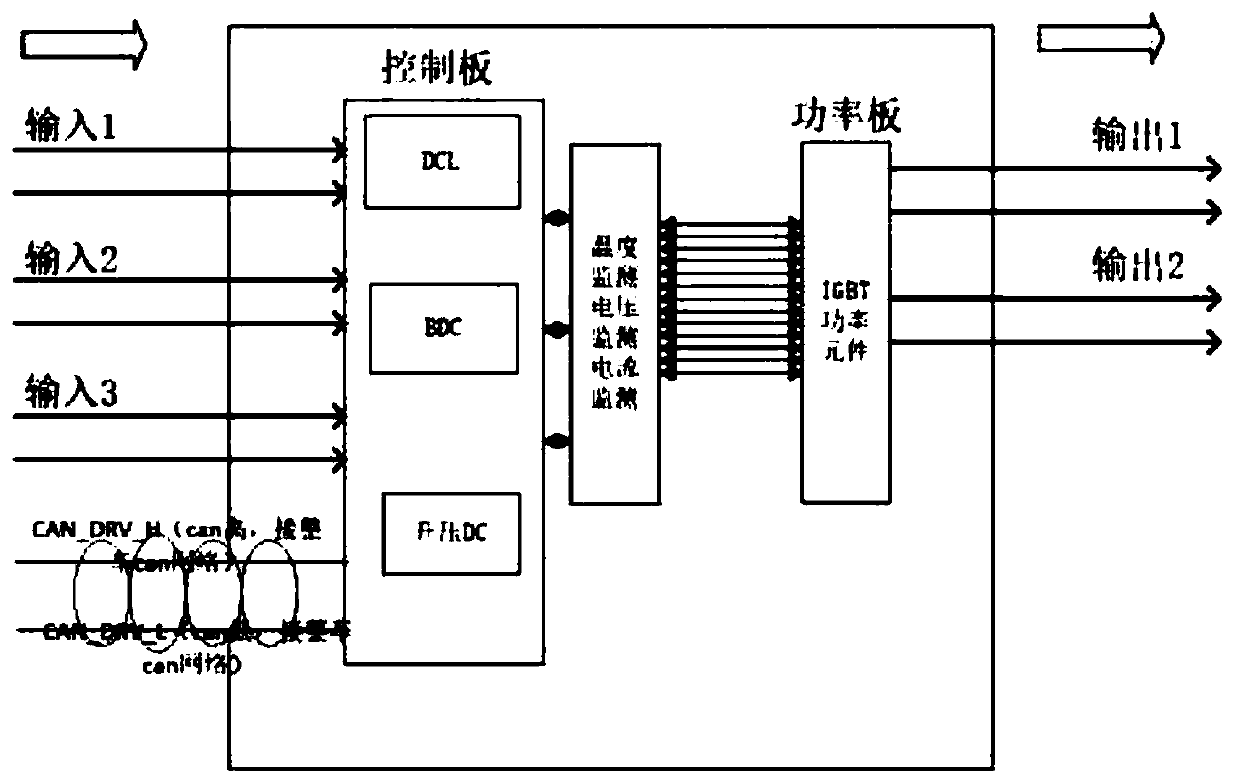

[0033] Embodiment one: refer to Figure 1-2 , an integrated DCDC system for hydrogen fuel cell vehicles, including a control board and a power board, the control board is provided with a relay and a fuse, and the control board is provided with an input interface, and there are three input interfaces, namely input 1, Input 2 and input 3, IGBT components are set on the power board, and output interfaces are set on the power board, and there are two output interfaces in total, namely output 1 and output 2, the control board and the power board directly use pins Connection, input 1 is the high-voltage output of the hydrogen fuel cell system, input 2 is the high-voltage output of auxiliary energy 1, input 3 is the high-voltage output of auxiliary energy 2, output 1 is the 12V battery, and output 2 is the high-voltage power distribution unit PDU.

Embodiment 2

[0034] Embodiment two: refer to figure 2 , The IGBT component is a composite fully-controlled voltage-driven power semiconductor device composed of BJT (bipolar transistor) and MOS (insulated gate field effect transistor), which has both high input impedance of MOSFET and low conduction voltage drop of GTR. The saturation voltage of GTR is reduced, the current carrying density is large, but the driving current is large; the driving power of MOSFET is small, the switching speed is fast, but the conduction voltage drop is large, and the current carrying density is small. IGBT combines the advantages of the above two devices, and the driving power Small and low saturation pressure. It is very suitable for the conversion system with a DC voltage of 600V and above, such as AC motors, frequency converters, switching power supplies, lighting circuits, and traction drives. The IGBT module has the characteristics of energy saving, convenient installation and maintenance, and stable he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com