Feed composition and preparation and application thereof

A feed composition and raw material technology, applied in the field of improving intestinal health of piglets and feed composition, can solve problems such as poor diarrhea effect of piglets, achieve the goal of improving intestinal microenvironment, improving intestinal environment, and reducing intestinal pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

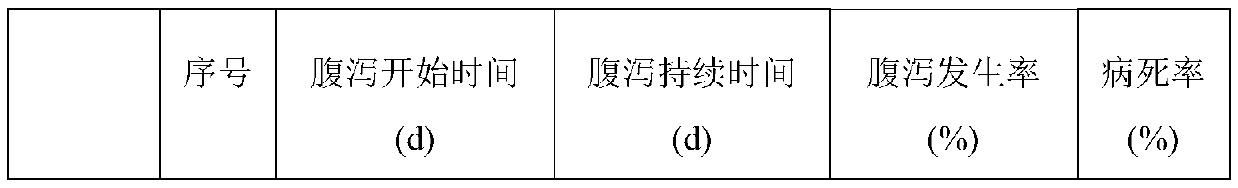

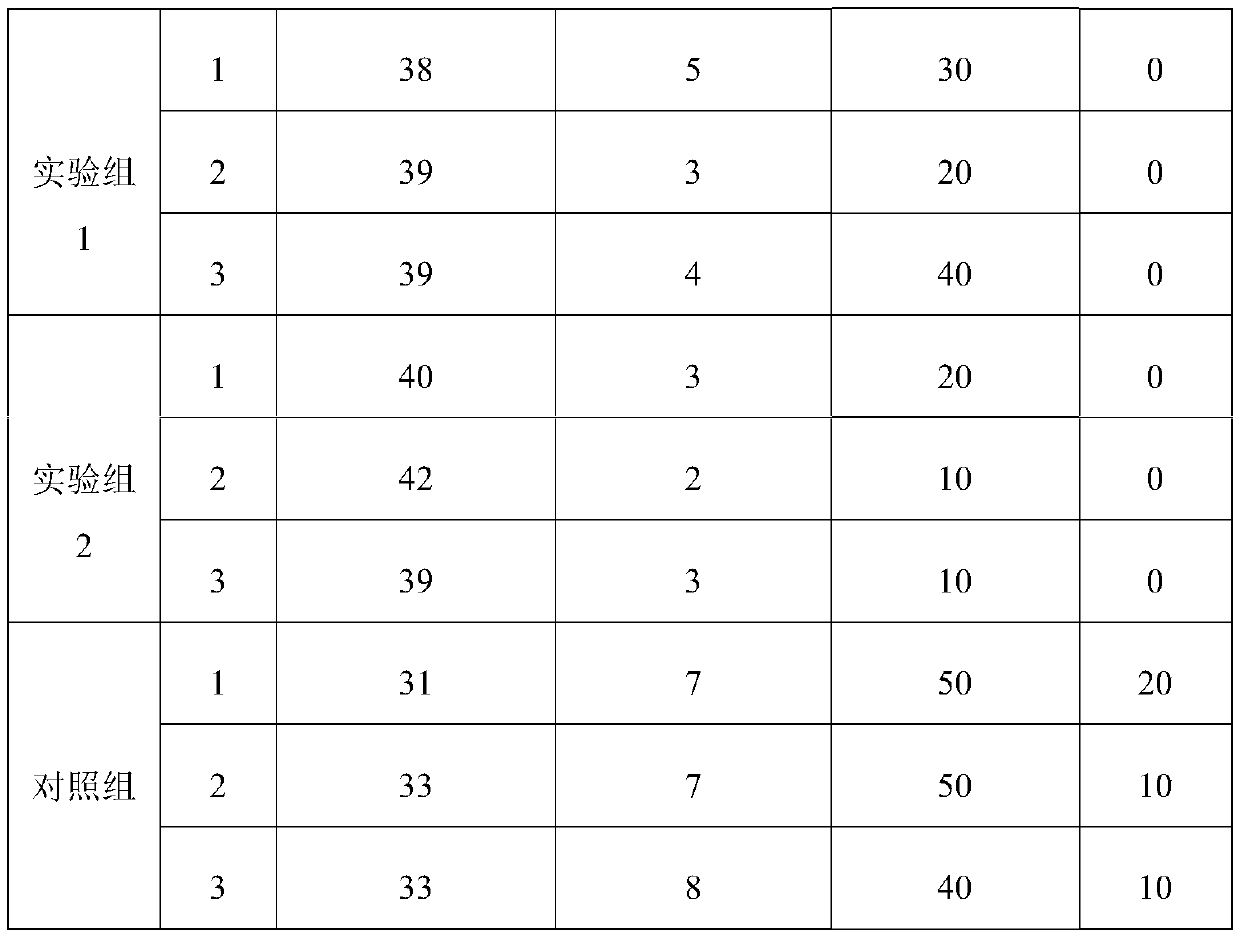

Examples

Embodiment 1

[0030] The present embodiment provides a kind of concrete implementation of piglet feed, specifically as follows:

[0031] Preparation of high-immune egg yolk powder: Take healthy 150-180-day-old Roman brown-shell hens, inject 0.5-2ml of porcine ETEC triple vaccine / feather at multiple points in the breast and legs, and boost the immunization once 20 days later, and produce 40 days after the first immunization Eggs can become the high-free eggs used in this embodiment. Soak the high-free eggs in 1% geeramine solution for 60 minutes, take them out, dry them, open them, separate the egg yolks, and make egg yolk slurry, and use spray drying to dry the fresh egg yolks. The pulp is quickly dehydrated and dried into high-quality egg yolk powder, which is sealed and stored for later use.

[0032] Preparation of amylase enteric-coated granules: Take 0.08kg of solid α-amylase for feed, 0.02kg of solid glucoamylase, 0.1kg of hydroxypropyl cellulose, 0.05kg of mannitol, 0.1kg of montmoril...

Embodiment 2

[0036] The present embodiment provides a kind of concrete implementation of piglet feed, specifically as follows:

[0037] Preparation of high-free egg yolk powder: according to the preparation method of high-free egg yolk powder described in Example 1, high-free egg yolk powder was prepared.

[0038] Preparation of amylase enteric-coated granules: Take 0.12kg of solid α-amylase for feed, 0.05kg of solid glucoamylase, 0.15kg of hydroxypropyl cellulose, 0.1kg of mannitol, 0.2kg of montmorillonite, 0.2kg of glycerin, and stir at 300rpm After 60 minutes, it is a semi-dry mixture. Use a type spherical shot blasting machine to make the above semi-dry mixture into spherical particles of 0.1-1mm, dry it with hot air at 40°C, and then place the spherical particles in a fluidized bed coating machine. Diformic acid hydroxypropyl methylcellulose 0.15kg, propylene glycol 0.02kg, glucose 0.2kg is dissolved in water and made mass fraction and is that 20% water dispersion joins in the liquid...

Embodiment 3

[0042] The present embodiment provides a kind of concrete implementation of piglet feed, specifically as follows:

[0043] Preparation of high-free egg yolk powder: according to the preparation method of high-free egg yolk powder described in Example 1, high-free egg yolk powder was prepared.

[0044] Preparation of amylase enteric-coated granules: Take 0.1kg of solid α-amylase for feed, 0.4kg of solid glucoamylase, 0.12kg of hydroxypropyl cellulose, 0.08kg of mannitol, 0.15kg of montmorillonite, 0.15kg of glycerin, and stir at 200rpm After 60 minutes, it was a semi-dry mixture. Use a type spherical shot blasting machine to make the above semi-dry mixture into spherical particles of 0.1-1mm, dry with hot air at 40°C, and then put the spherical particles in a fluidized bed coating machine, take acetic acid ortho Cellulose phthalate 0.12kg, propylene glycol 0.02kg, glucose 0.2kg make mass fraction and join in the fluid reservoir of coating machine as coating agent, open air comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com