Servo power module

A technology of power supply module and power input terminal, applied in electrical components, adjusting electrical variables, instruments, etc., can solve the problems of power supply stability, large size, and low output power affecting the subsequent equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

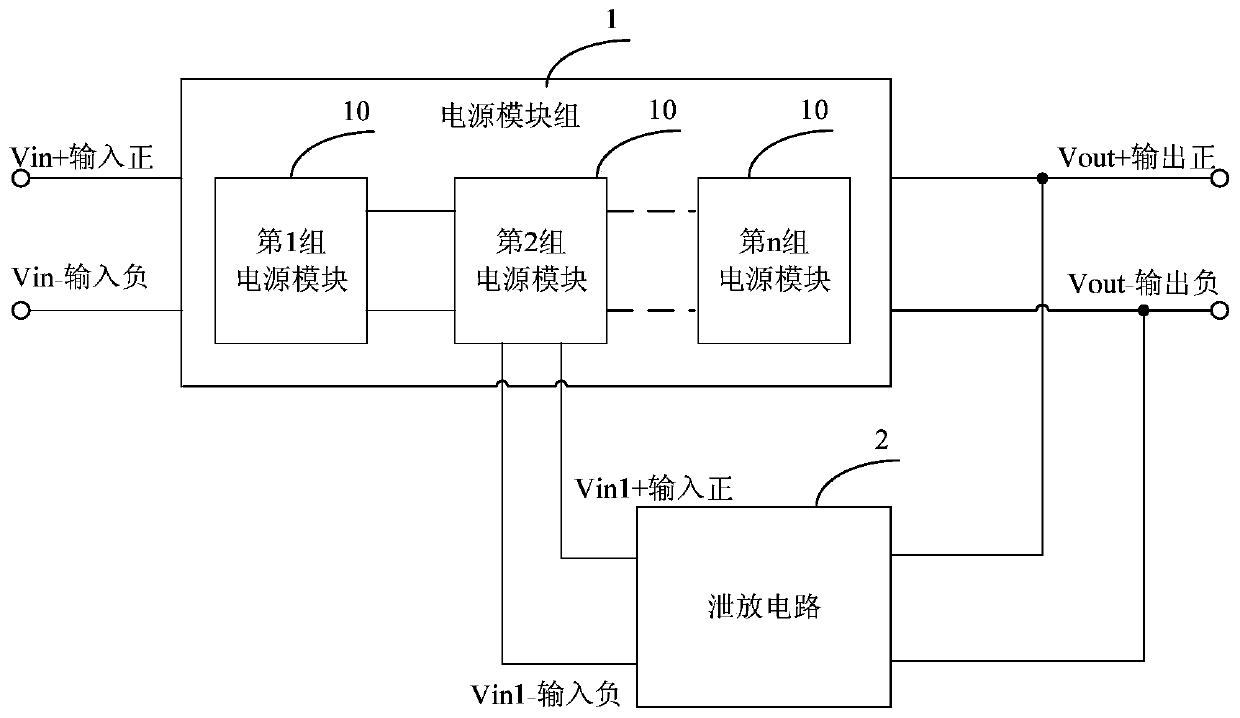

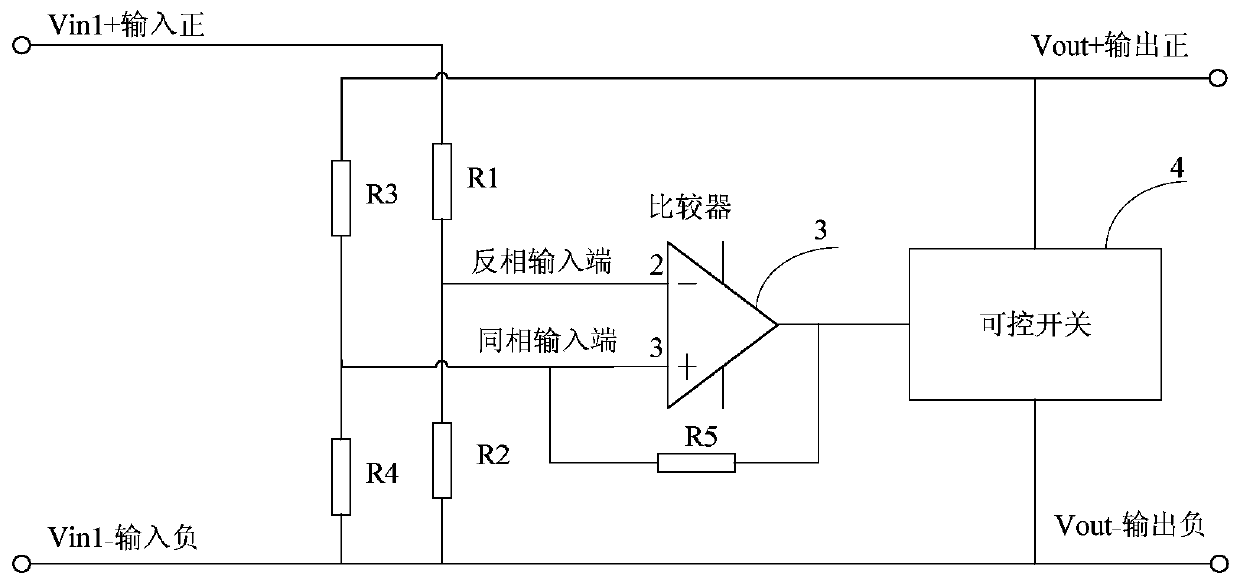

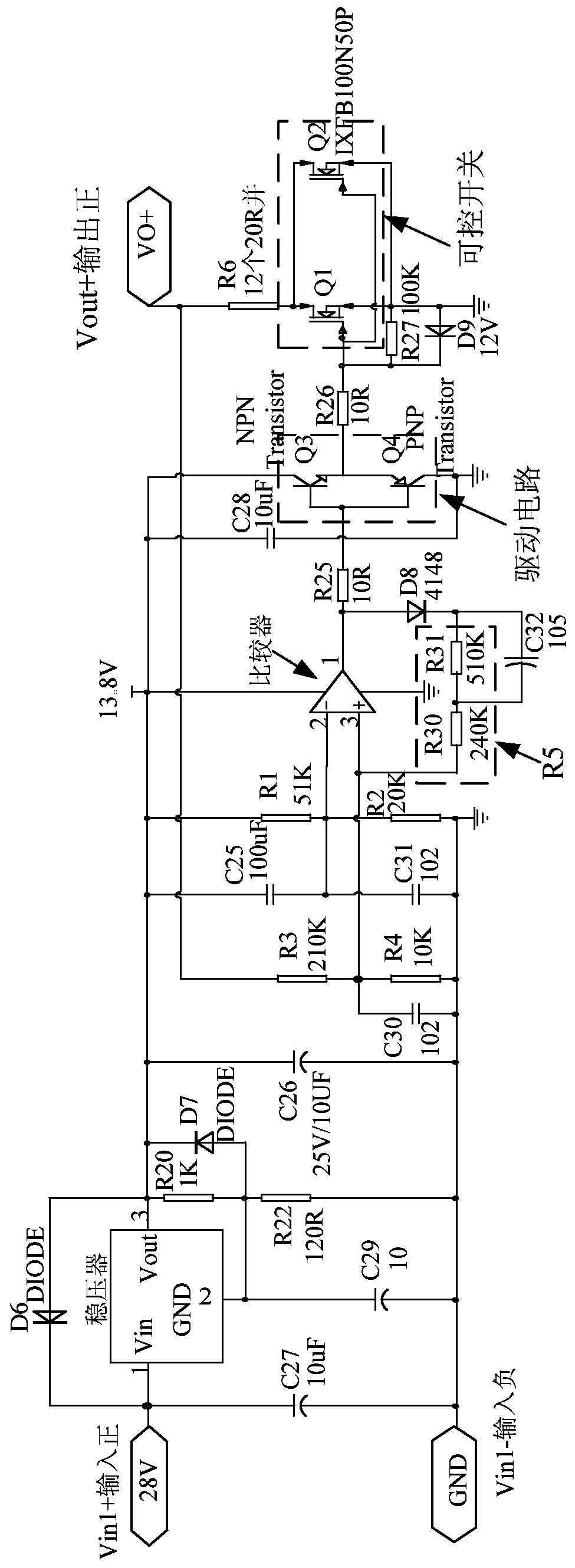

[0024] In order to solve the problems in the prior art that the servo power module has a large volume, poor instantaneous power performance, and the pumping voltage of the motor causes disturbance to the voltage at the output end of the servo power module, the present disclosure provides a servo power module, including a power module group and a discharge circuit, wherein the power module group is composed of several power modules in series, each power module can have different voltage and power output, and several power modules are combined in series, the power module group can achieve a larger voltage and power output, It can overcome the limitation of high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com