Corrosion-resistant metal lithium negative current collector and preparation method and application thereof

A current collector and metal lithium technology, which is applied in the field of metal lithium negative electrode current collectors and its preparation, can solve the problems of insulation corrosion products and electrode structure collapse, corrosion, battery failure, etc., to inhibit dendrite growth, promote uniform distribution, The effect of stabilizing the solid-liquid interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

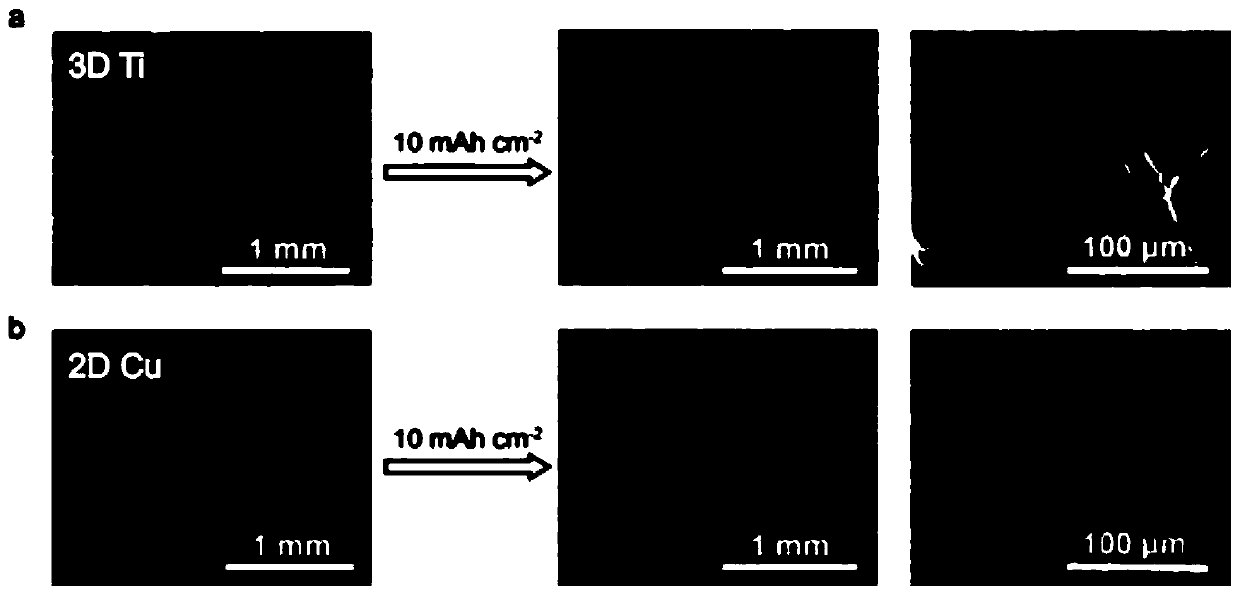

[0027] In a glove box filled with argon, a corrosion-resistant metal titanium current collector and a comparative copper foil current collector were used as negative electrodes, metal lithium was used as a reference electrode and a counter electrode, and Celgard 2325 was used as a diaphragm to assemble a coin cell. The electrolytic solution used in the present invention is composed of a certain concentration of lithium salt, an organic solvent and a small amount of electrolytic solution additives. Wherein the lithium salt is lithium bistrifluoromethylsulfonylimide (LiTFSI), the solvent is 1,3-dioxane / ethylene glycol dimethyl ether (DOL / DME), and the electrolyte additive is 1wt% lithium nitrate ( LiNO 3 ) and 0.1M lithium polysulfide (Li 2 S 8 ). Use an electrochemical workstation (CHI 760E) to perform a cyclic voltammetry scan test on the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com