A Parallel Multi-objective Machining Parameter Optimization Method Responding to Dynamic Disturbance

A processing parameter and multi-objective technology, applied in the direction of program control, instrument, computer control, etc., can solve problems such as low real-time requirements of algorithms, inapplicability of processing parameter optimization, ignoring dynamic disturbance events, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

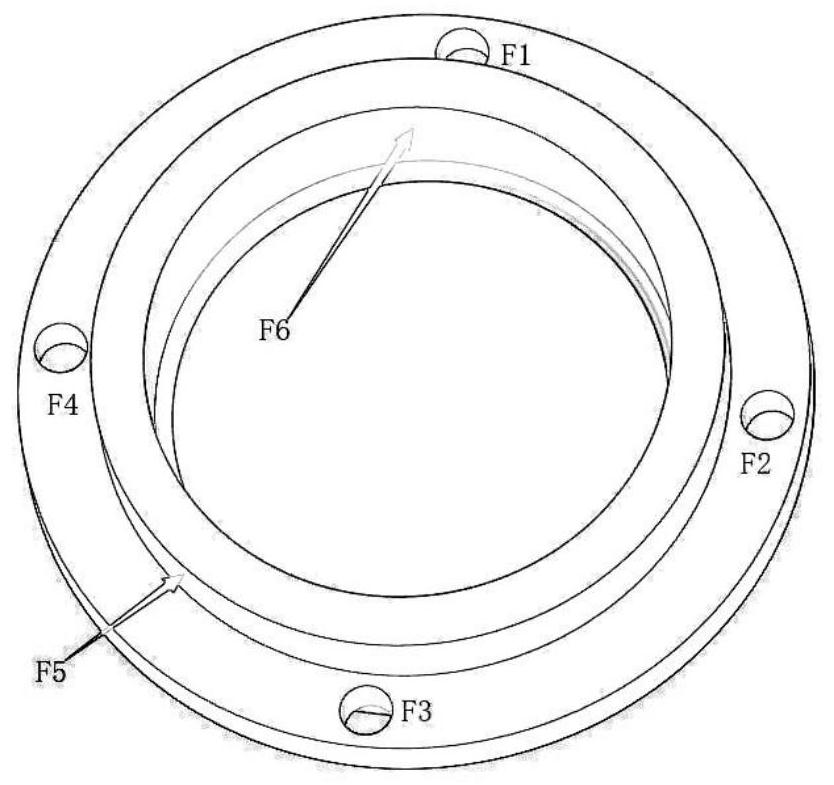

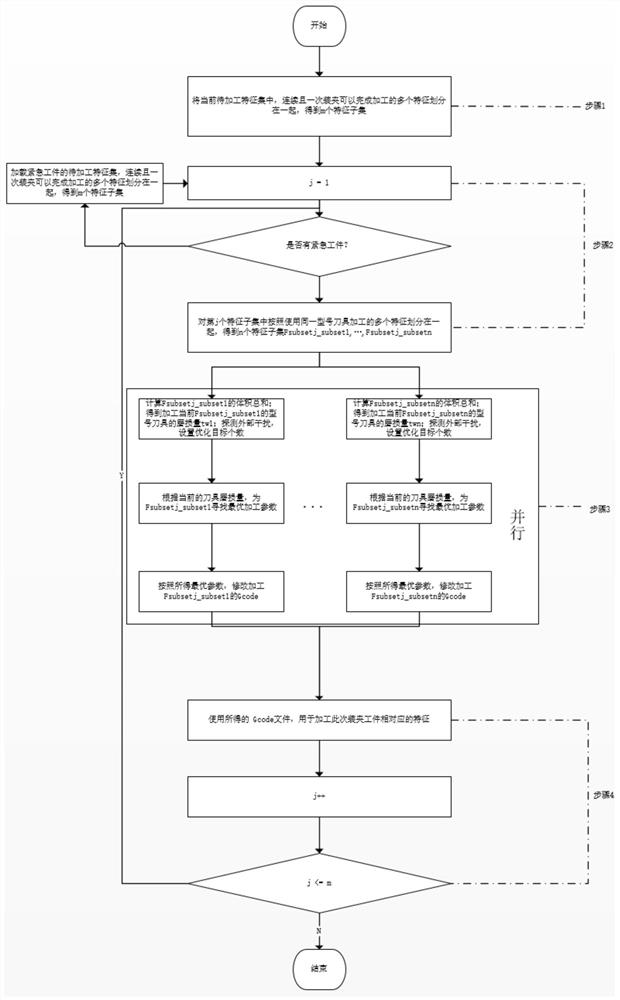

[0072] Step 2, without urgent workpiece disturbance, load F subset1 , the tool model used to process {F1, F2, F3, F4} is HRC45LYD (8*24*3T*60L), so divide {F1, F2, F3, F4} into the same feature subset to get F subset1_subset1 , the tool model used to process {F6,F5} is HRC45LYD (10*30*3T*75L), so divide {F6,F5} into the same feature subset to get F subset1_subset2 , using parallelization, respectively F subset1_subset1 and F subset1_subset2 Find the optimal cutting process parameters;

[0073] Step 3, in a single parallelized process, load F subset1_subset1 (F subset1_subset2 ) to obtain feature subsets, and calculate F subset1_subset1 (F subset1_subset2 ) sum of characteristic volumes, F subset1_subset1 (F subset1_subset2 ) volume is V1 (V2) to detect the current external interference event, set the number of initial optimization targets to be 3 (3), and read and process the current feature subset F subset1_subset1 (F subset1_subset2 ) The wear amount tw1(tw2) of th...

Embodiment 2

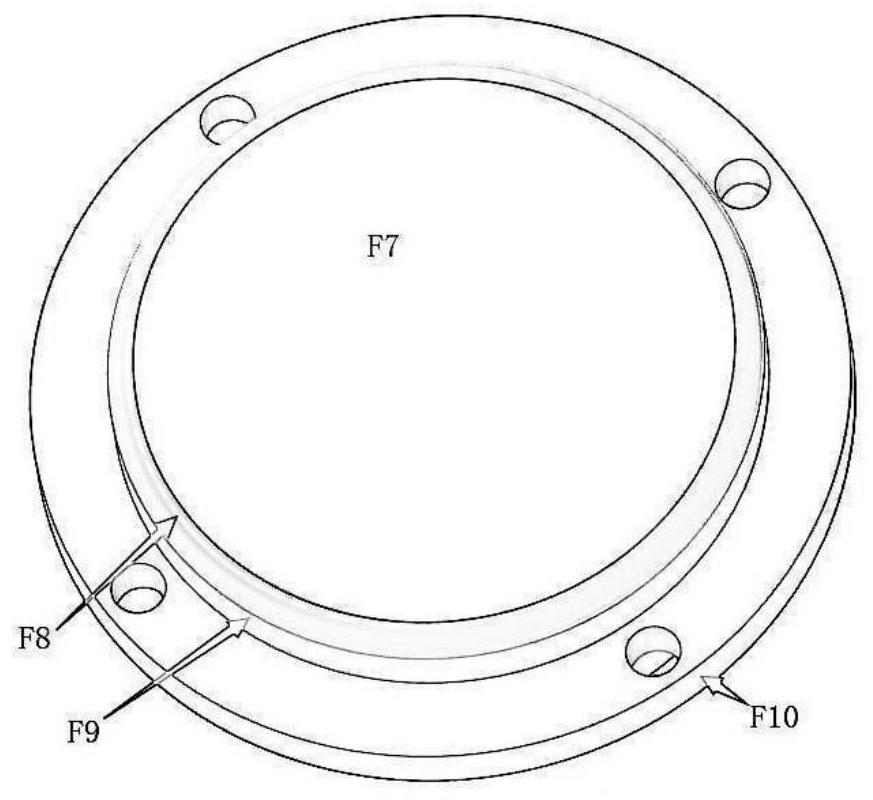

[0083] Step 2, without urgent workpiece disturbance, load F subset2 , the tool model used to process {F7, F9, F10} is HRC45LYD (8*24*3T*60L), so divide {F7, F9, F10} into the same feature subset to get F subset2_subset1 , the tool model used to process {F8} is JE25DJD (3*50L*90°), so {F8} is the feature subset F subset2_subset2 , using parallelization, respectively F subset2_subset1 and F subset2_subset2 Find the optimal cutting process parameters;

[0084] Step 3, in a single parallelized process, load F subset2_subset1 (F subset2_subset2 ) to obtain feature subsets, and calculate F subset2_subset1 (F subset2_subset2 ) sum of characteristic volumes, F subset2_subset1 (F subset2_subset2 ) volume is V3 (V4) to detect the current external interference event, set the number of initial optimization targets to be 3 (3), and read and process the current feature subset F subset2_subset1 (F subset2_subset2 ) The wear amount tw3 (tw4) of the type tool used is based on the est...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com