Method for measuring thickness of nanoscale film by utilizing photon spin Hall effect

A technology of spin Hall effect and thin film thickness, applied in the optical field, can solve the problems of low system assembly accuracy, difficult to popularize and apply on a large scale, low accuracy of turntable, etc., meet the requirements of low instrument requirements, suitable for large-scale application, high precision The effect of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

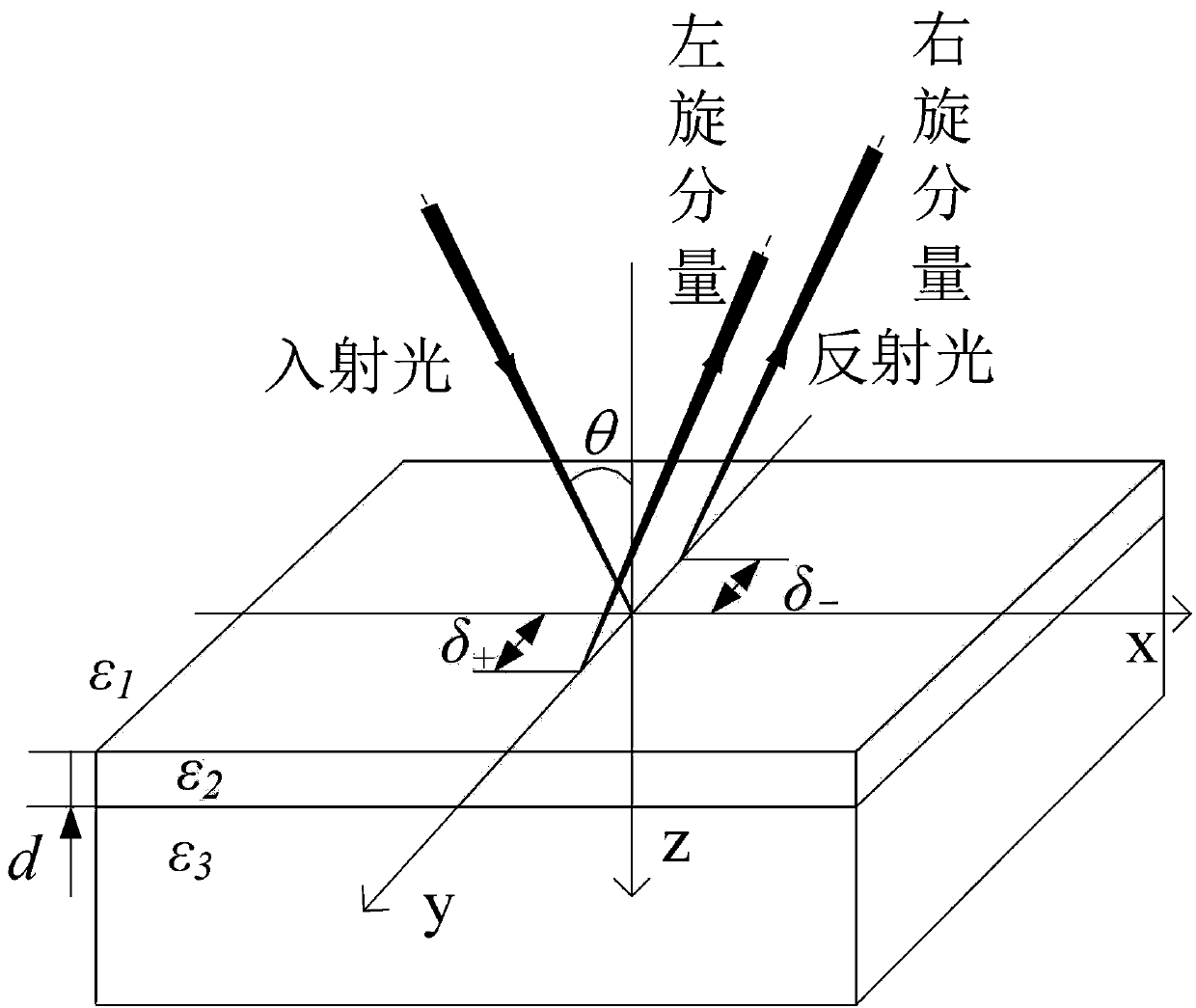

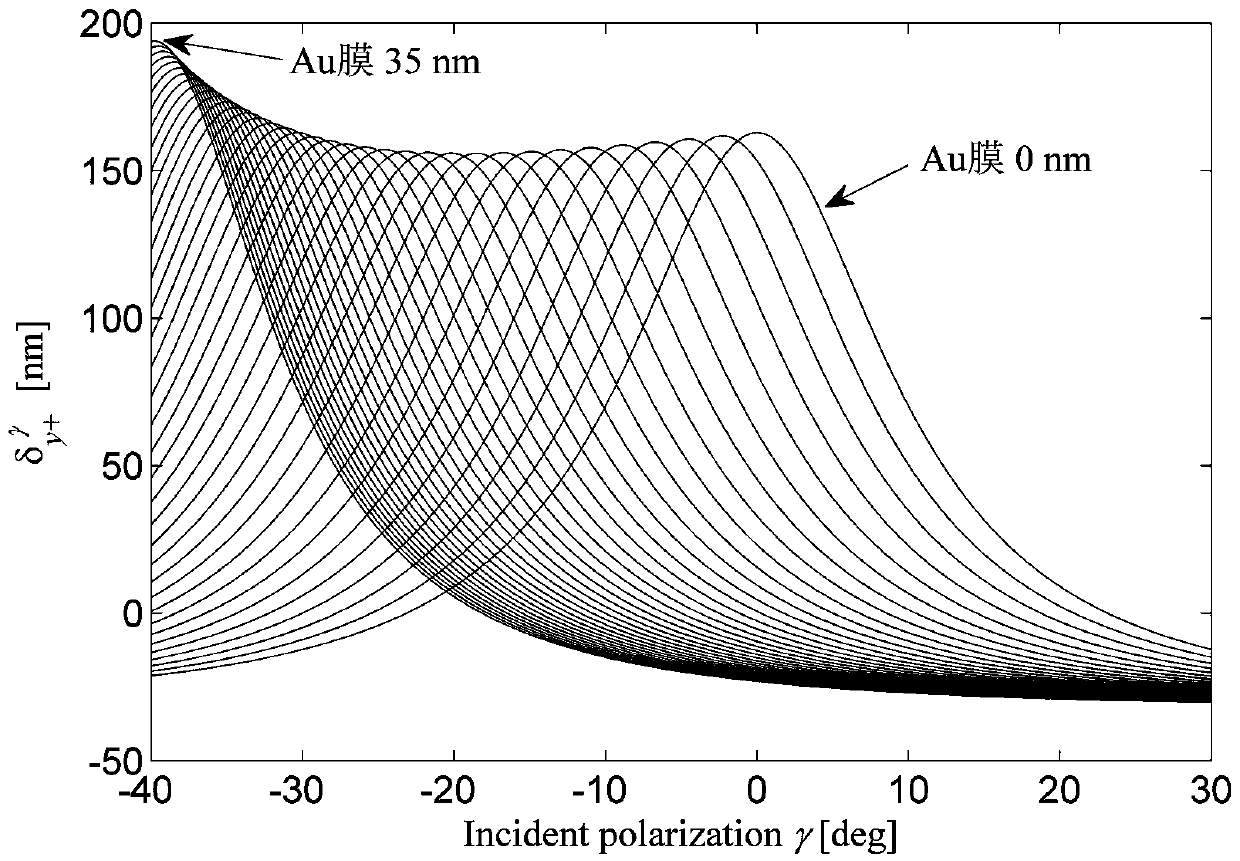

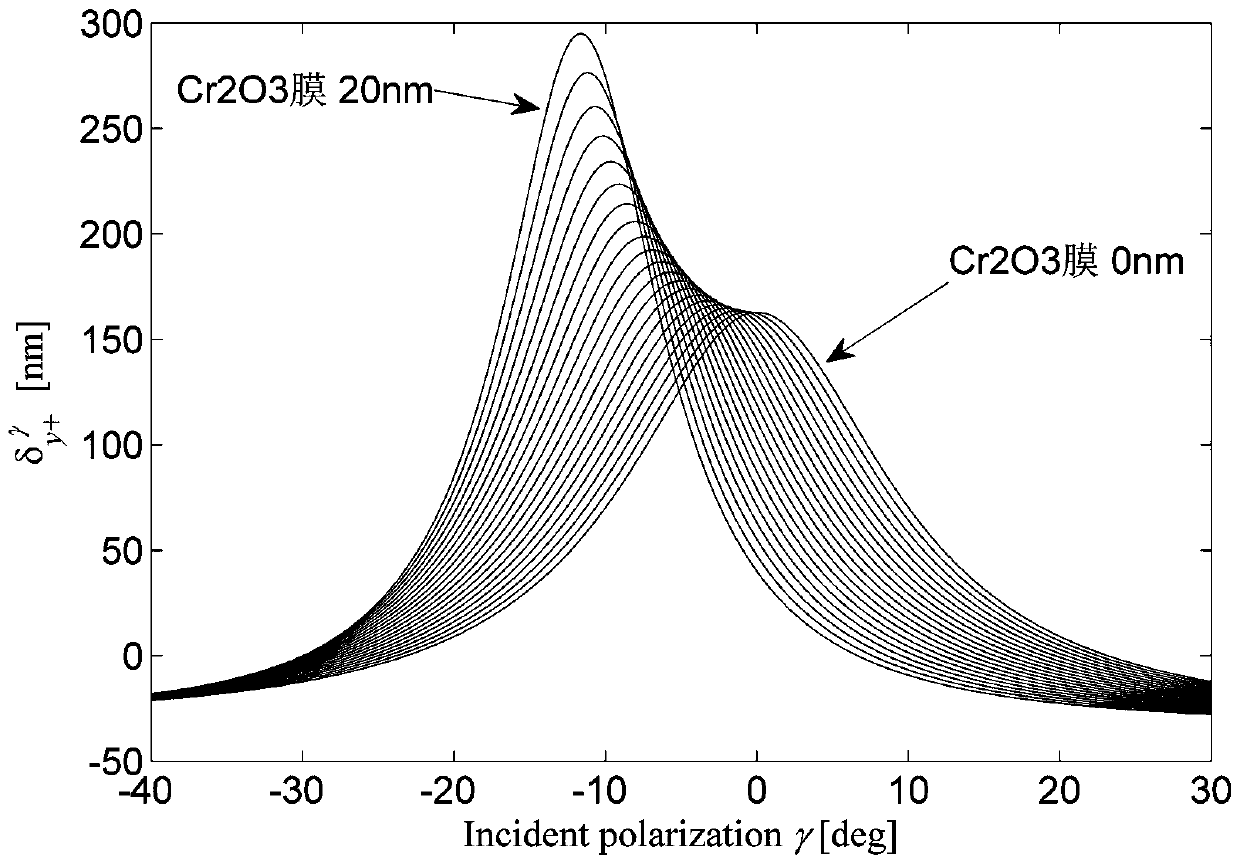

[0040] A method to measure the thickness of nanoscale films by using the photon spin Hall effect, and then to measure the metal material gold Au and the non-metal material chromium trioxide Cr 2 o 3 film thickness as an example, refer to Figure 10 The step flow chart describes in detail the specific implementation process of the present invention.

[0041] The incident light beam that adopts in the embodiment of the present invention is that wavelength is 632.8nm, beam waist w 0 Gaussian bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com