Sewage pipeline laying process

A technology for sewage pipes and pipelines, which is applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc. It can solve the problems of track influence accuracy and high requirements for guide rail design, and achieve simple construction and good sealing performance of pipeline joints Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

[0032] Tool introduction:

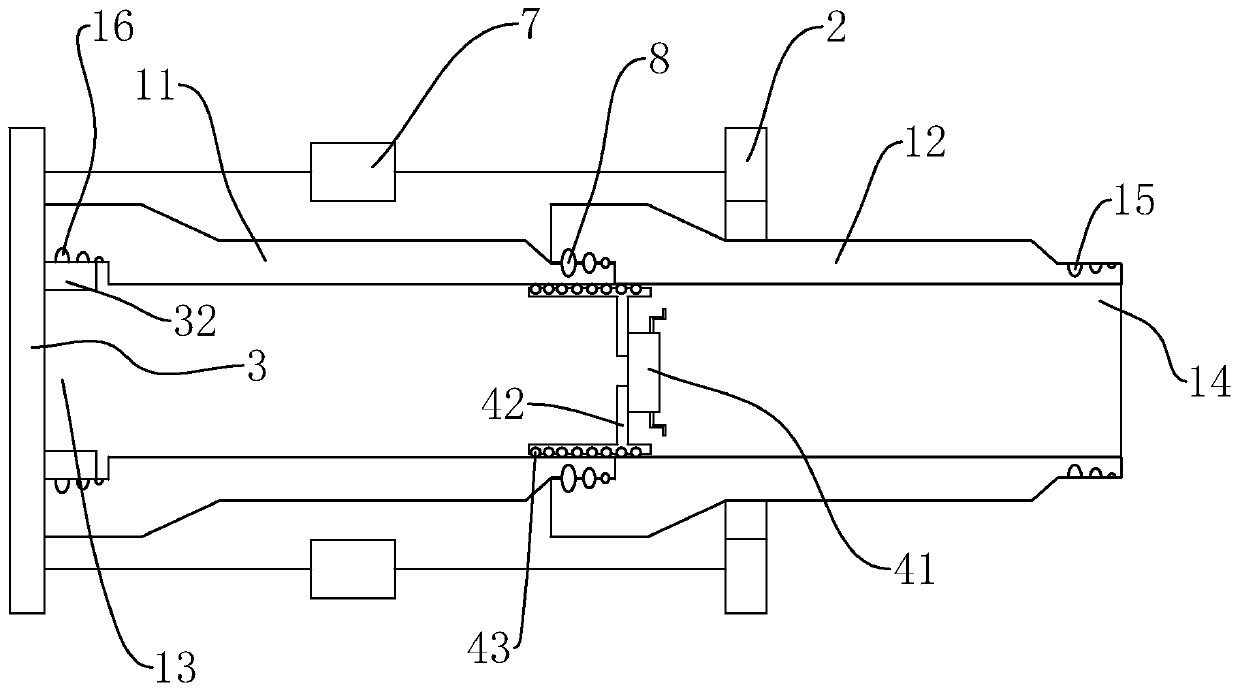

[0033] Such as figure 1 , the pipeline has a socket 13 and a socket 14, and the external diameter of the socket 14 of the pipeline is smaller than the internal diameter of the socket 13.

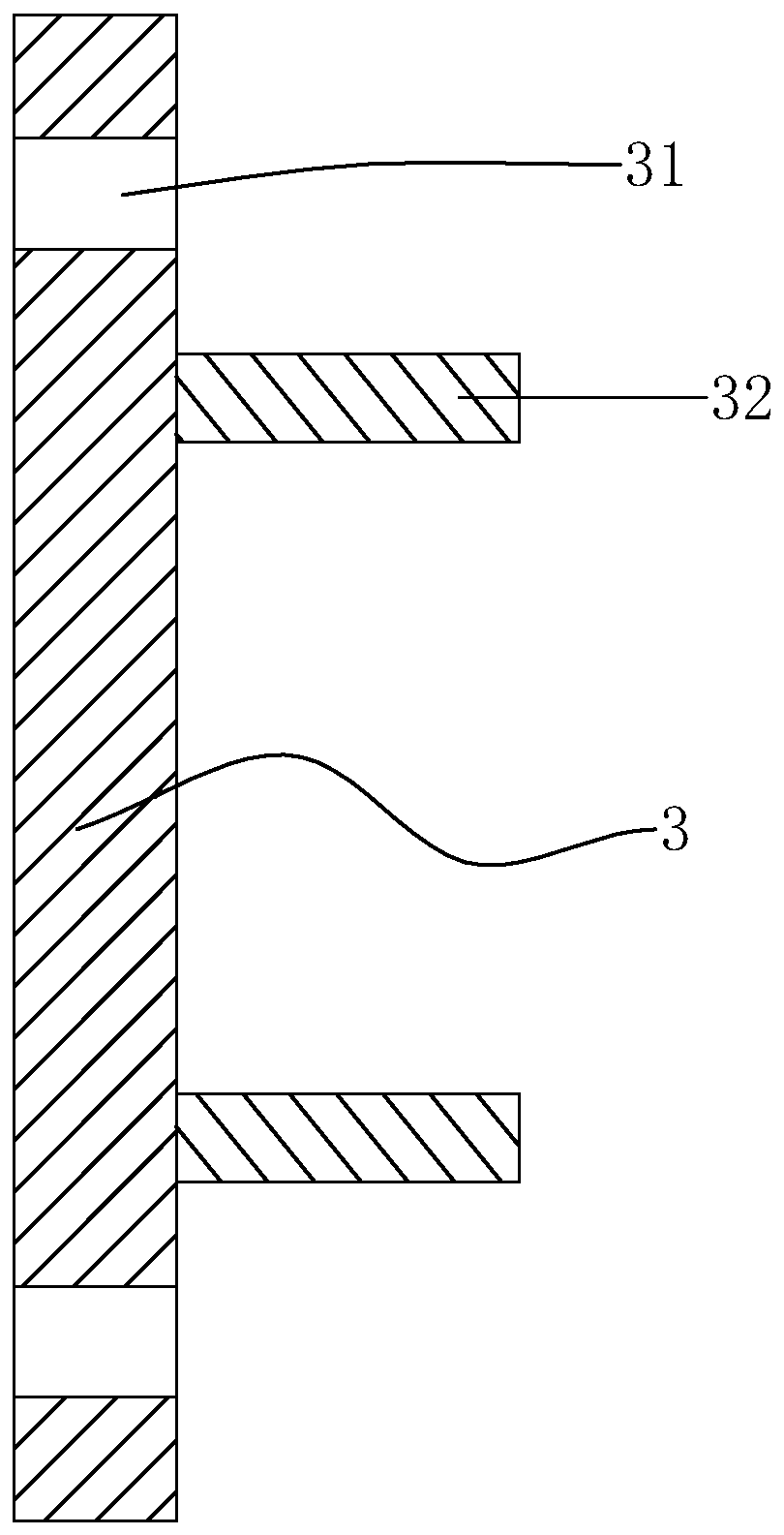

[0034] Such as Figure 4 , The clamp 2 is formed by butt jointing of two connecting rings 21 whose radian is less than π, the inner diameter of the connecting ring 21 is the same as the diameter of the middle part of the pipe, and the bolt 23 passes through the extensions 22 of the two connecting rings 21 and connects the nut 24 at the same time.

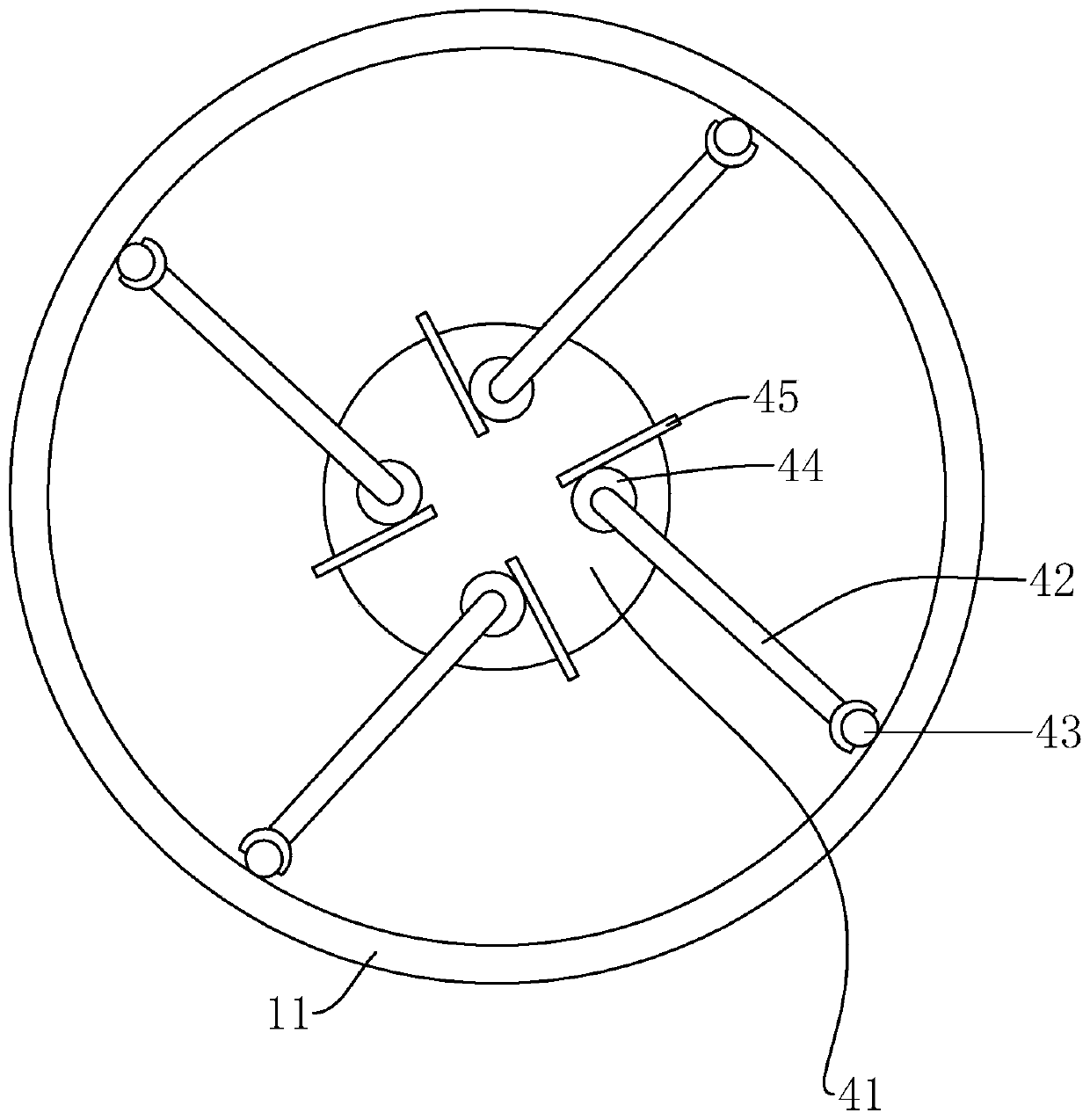

[0035] Such as image 3 , the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com