Method and device for controlling dual-motor variable-pitch system

A technology of pitch control system and control method, which is applied in the control of wind turbines, engine control, multiple motor speed adjustments, etc., and can solve problems such as difficulties in maintenance and replacement, large parts with high mass, and limited volume of hubs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

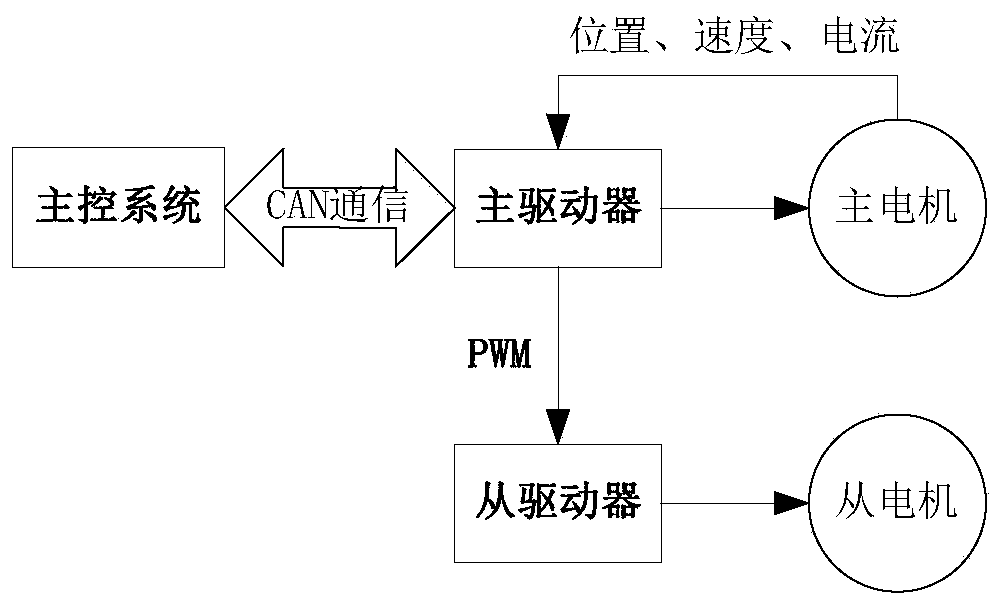

[0024] This embodiment provides a control method for a dual-motor pitch system. In order to realize this method, the following methods are used: figure 1 The two-motor pitch system shown. The system includes a master driver and a slave driver, which respectively control the master motor M1 and the slave motor M2, and the data exchange between the master motor and the master control system is carried out through the CAN bus. Both the master driver and the slave driver here include a processor and a motor controller, which can not only process signals, but also control the motor.

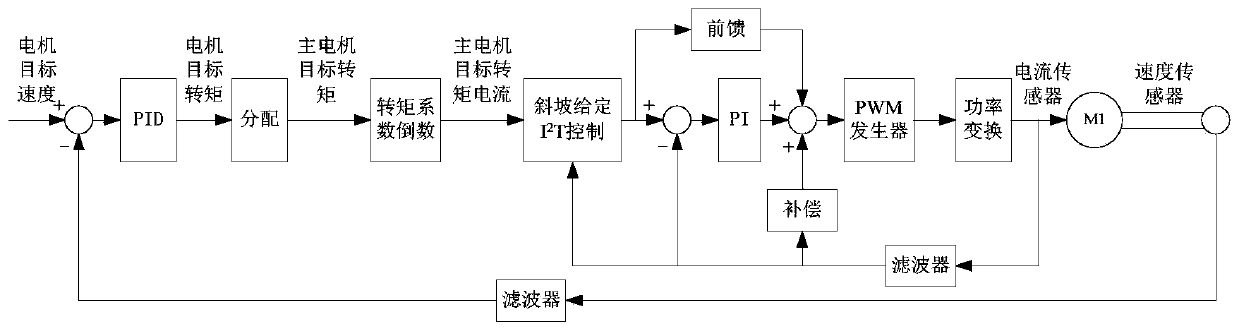

[0025] The main driver receives the target position of the blade (that is, the angle of the blade) issued by the main control system, and compares the current position of the currently recorded blade with the received target position of the blade to obtain the target speed of the motor. The speed includes not only the speed of the motor, but also the direction in which the motor needs to rotate. Afte...

Embodiment 2

[0039] This embodiment provides a control method of a dual-motor pitch system, in order to realize this method adopts such as figure 1 system shown. However, the difference between the system of this embodiment and Embodiment 1 is that the functions realized by the master driver and the slave driver are different.

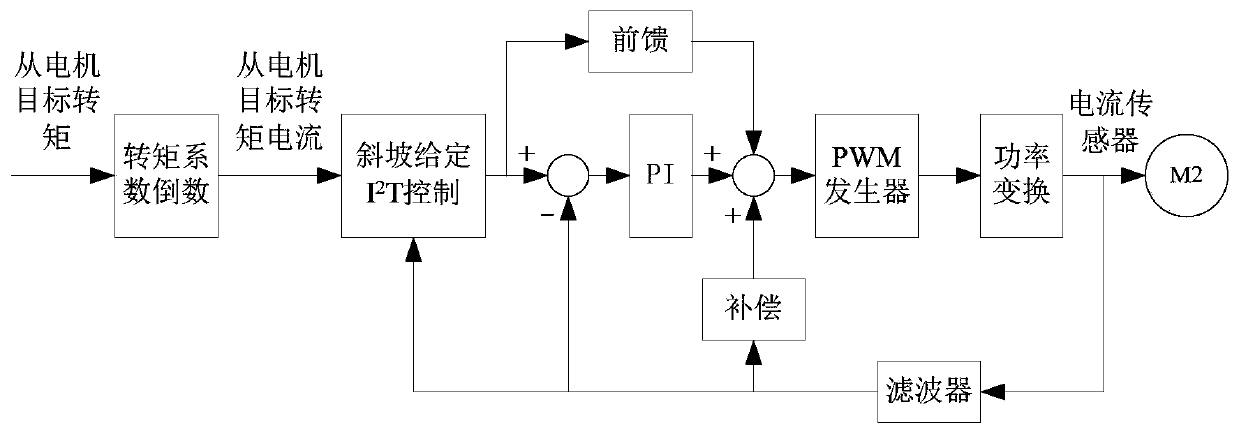

[0040] The master driver in this embodiment includes a processor and a motor controller, and the slave driver includes a motor controller, and the PWM signal sent by the master driver to the slave driver is no longer a square wave frequency signal about the target torque of the slave motor , but to control the control signal from the switching tube of the motor controller in the driver.

[0041] The main driver receives the target position of the blade issued by the main control system, and compares the current position of the recorded blade with the received target position of the blade to obtain the target speed of the motor. The target speed of the motor includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com