Needlework technology

A technology of craft and craft steps, applied in the field of embroidery craft, can solve the problems of scrapped embroidery, low production efficiency, irregularity, etc., and achieve the effect of good artistic effect, high production efficiency and strong decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Here is an example of a lotus petal:

[0028] see figure 1 , a kind of embroidery process, its process step is as follows:

[0029] A. First make a sample according to the size of the lotus petals to be made;

[0030] B. Enlarge the sample according to the required size;

[0031] C. Select the fabric, the fabric requirement is based on the thickness and thickness required for the lotus petal embroidery, and it is white;

[0032] d. Use carbon paper to trace the enlarged sample on the fabric, and outline the pattern lines;

[0033] E. Flatten the painted fabric with lotus petal pattern and nail it on the wooden board;

[0034] f. Find the light and dark silk threads needed for the lotus petals and cut them into lint;

[0035] G. Prepare a disposable plastic cup, cut the plastic cup in half, and leave the bottom side for later use;

[0036] H. Prepare a toothpick for stirring and hooking;

[0037] i. Prepare the glue for the paste;

[0038] j. Put the ve...

Embodiment 2

[0041] see figure 2 , When embroidering trees, first draw the sample, then cut the silk light of dark and light colors into short lines about one centimeter in length. The short lines are spread on the light-colored background to form a three-dimensional effect; the same method can be embroidered on the grass or small trees on the mountain. The picture produced in this way has the characteristics of both oil painting and meticulous painting. The variability is also very strong, so that each work can be unique, while avoiding the three-dimensional effect that cannot be achieved by embroidery and painting;

Embodiment 3

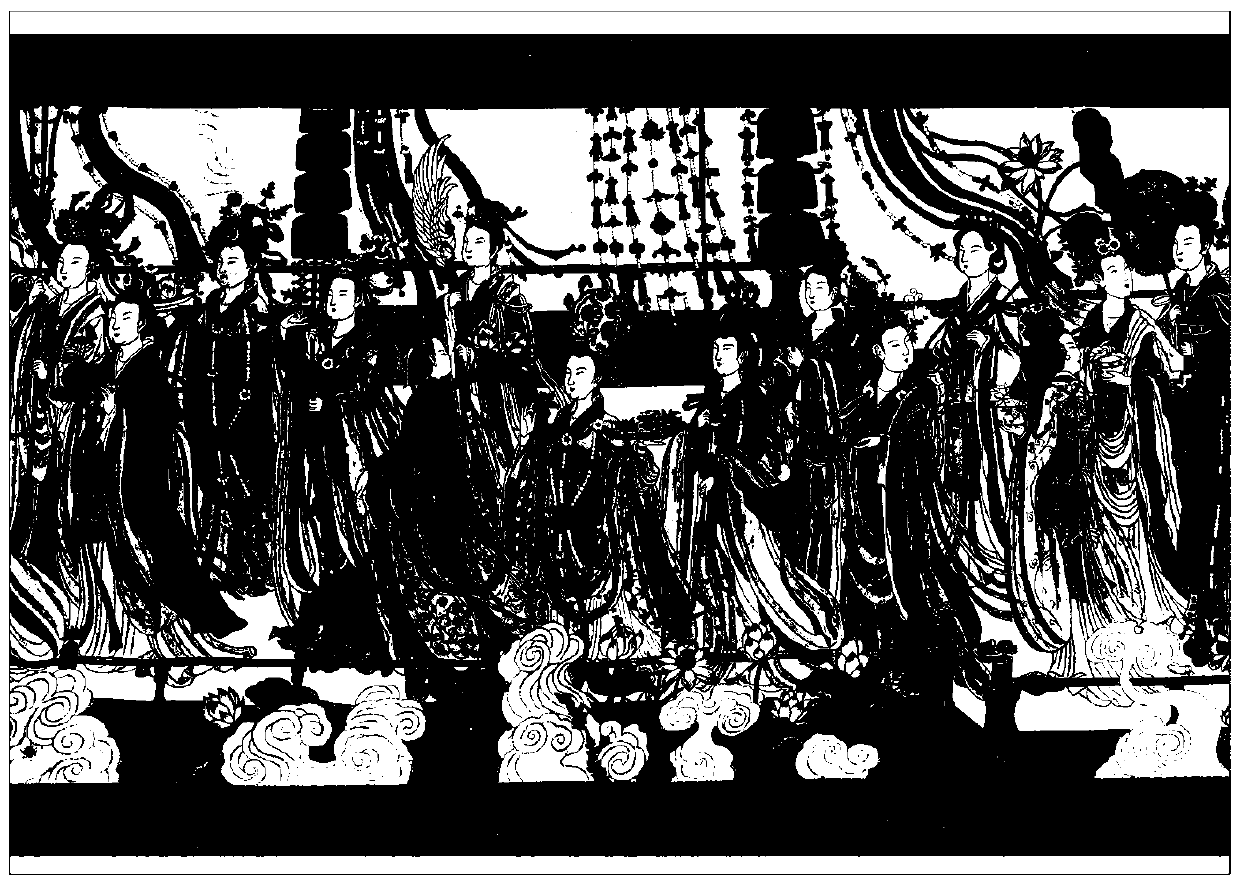

[0043] see image 3 , When embroidering the accessories on the characters, in order to achieve the effect of three-dimensional simulation, it must be high and thick when smudged, so that it can be formed. For example: for the bead chain on the character, when making beads, you must first adjust the wool into a soybean-shaped circle, repeat this two to three times, pile up high and thick, and then it will be three-dimensional and full after air-drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com