3D silica gel membrane with fabric layer and preparation method and application thereof

A fabric layer, silicone film technology, applied in textiles and papermaking, vehicle parts, transportation and packaging, etc., can solve the problems of flat silicone film or hard mold that cannot meet product requirements, increased manufacturing costs, and limited service life. The effect of uniform surface force, long service life and large applied pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of a 3D silica gel membrane with a fabric layer, comprising the following steps:

[0026] The molding step is to make a basic model according to the shape of the required 3D silicone membrane;

[0027] In the step of brushing the release agent, apply the release agent evenly on the basic model, and let it stand to dry;

[0028] One step of applying silicone, apply liquid silicone and let it dry;

[0029] The second step of applying silica gel is to apply liquid silica gel, place the cut fabric on the liquid silica gel, press the fabric quickly with the soft bristles of the brush, so that the liquid silica gel can soak into the fabric, and let it stand to dry;

[0030] Apply silicone step three times, apply liquid silicone, let it dry;

[0031] In the demoulding step, remove the prepared 3D silicone membrane with fabric layer.

[0032] Further, the following steps are also included:

[0033] Repeat the steps, repeating the second silicone applica...

Embodiment 1

[0040] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

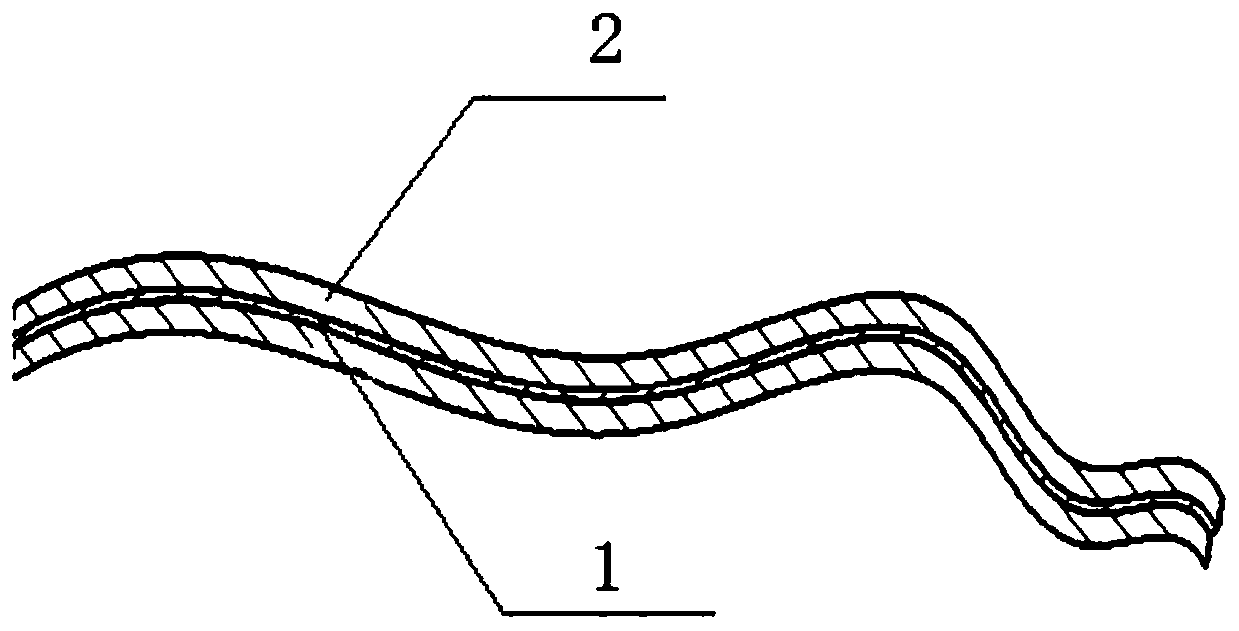

[0041] make a like figure 1 A 3-layer 3D silicone membrane with a fabric layer is shown, where the middle layer is a fabric layer (1) and the two outer layers are silicone layers (2).

[0042] The first step is the molding step. The basic model is made according to the shape of the required 3D silicone film. The basic model is made of machinable resin material, which is processed by CNC and has a smooth surface.

[0043] The second step is the step of brushing the release agent. Brush the release agent on the basic model, and use a scrub brush to apply the release agent evenly on the basic model. After the release agent is applied, let it dry for 2 hours, subject to the fact that the surface does not stick to hands, at this time, the first model is obtained.

[0044] The thi...

Embodiment 2

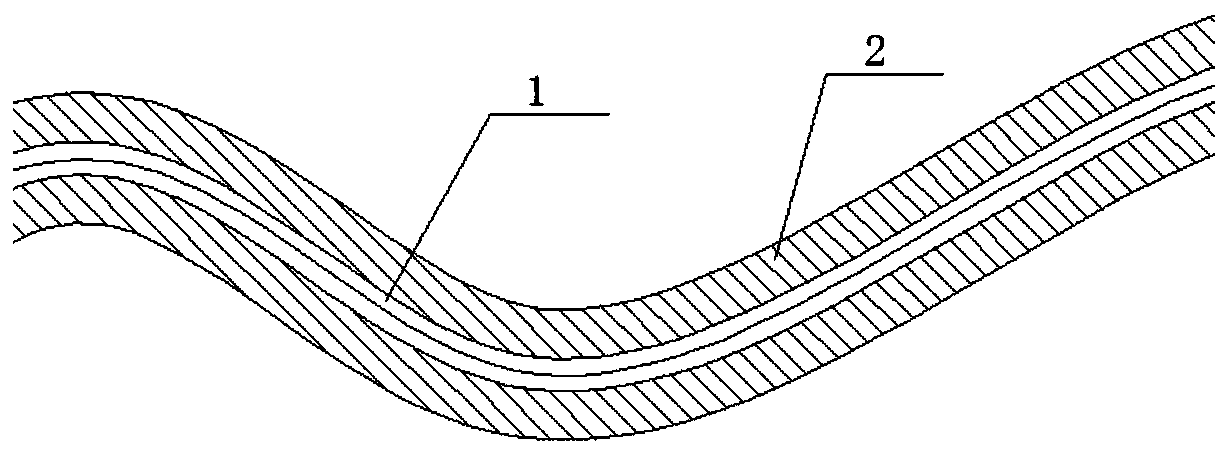

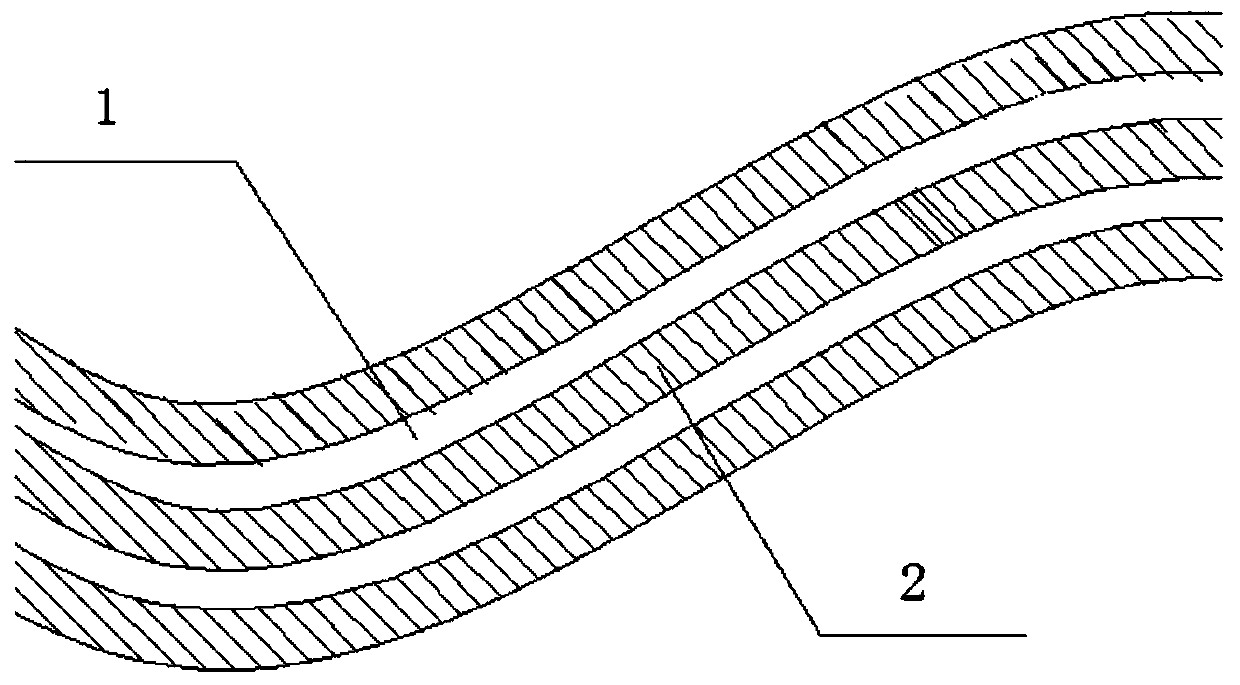

[0049] If you feel that the strength of the 3D silicone membrane with a fabric layer in Example 1 is not enough, you need to increase the number of fabric layers 1, you can repeat the fourth step on the dry model after the fourth step in Example 1 until After obtaining the number of layers of fabric layer 1 that meets the strength requirements, proceed to the fifth step, and you can get the following figure 2 The two outer layers shown are silicone layers 2 and a 3D silicone membrane with fabric layers containing multiple fabric layers 1 in the middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com