A kind of integrated automobile window lifter guide rail production material and its preparation method and application

A technology of automotive glass and lifter, which is applied in the direction of textiles and papermaking, papermaking, non-woven fabrics, etc., to achieve the effect of increasing the contact area, reducing the contact distance, and improving the effect of impregnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

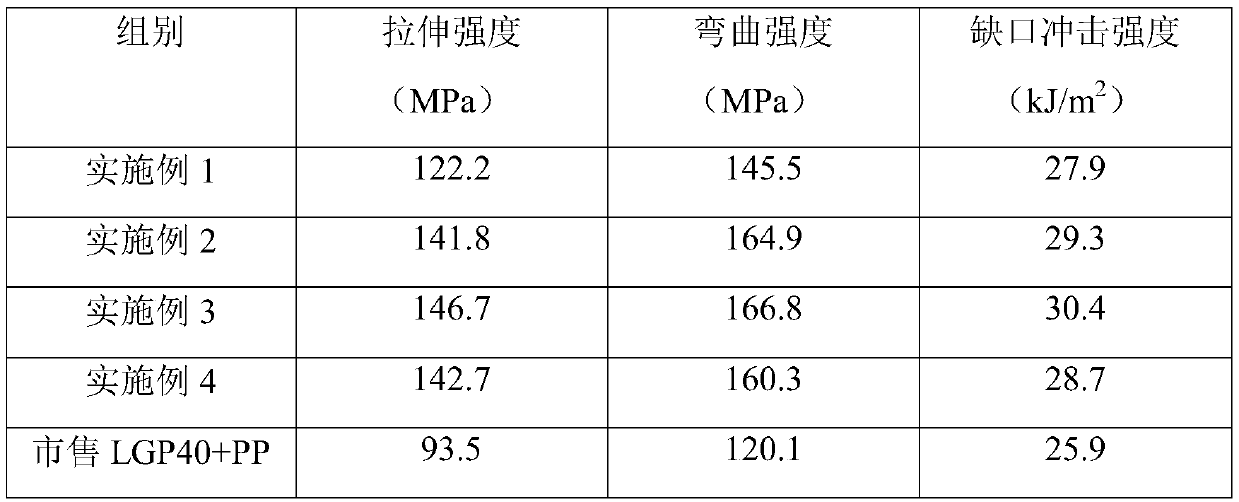

Examples

Embodiment 1

[0026] Embodiment 1: prepare long glass fiber reinforced polypropylene (LGF-PP) material as follows:

[0027] 1. Preparation of raw materials

[0028] Long glass fiber (LGF40) specific gravity 1.22g / cm 3 , monofilament diameter 10μm, pure polypropylene fiber specific gravity 0.92g / cm 3 , single filament diameter 11μm, the weight of the pure polypropylene filter is 180g / m 2 The pure polypropylene filter mesh is 50 mesh, and the surface of the long glass fiber has been treated with 10% silane coupling agent kh550 to improve the compatibility between the long glass fiber and the polypropylene substrate.

[0029] 2. Preparation of materials for the guide rail of the integrated automobile window lifter:

[0030] (1) The long glass fiber and pure polypropylene fiber after fiber spreading are respectively cut into 80mm fiber segments, and the long glass fiber and pure polypropylene fiber are weighed according to the long glass fiber content of 60wt%, and placed on the comb after m...

Embodiment 2

[0036] Embodiment 2: prepare long glass fiber reinforced polypropylene (LGF-PP) material as follows:

[0037] 1. Preparation of raw materials

[0038] Long glass fiber specific gravity (LGF20) 1.18g / cm 3 , monofilament diameter 11μm, pure polypropylene fiber specific gravity 0.90g / cm 3 , single filament diameter 11μm, the weight of the pure polypropylene filter is 227g / m 2 The pure polypropylene filter mesh is 100 mesh, and the surface of the long glass fiber has been treated with 10% silane coupling agent kh550 to improve the compatibility between the long glass fiber and the polypropylene substrate.

[0039] 2. Preparation of materials for the guide rail of the integrated automobile window lifter:

[0040] (1) The long glass fiber and pure polypropylene fiber after fiber spreading are respectively cut into 120mm fiber segments, and the long glass fiber and pure polypropylene fiber are weighed according to the long glass fiber content of 80wt%, and placed on the comb needl...

Embodiment 3

[0046] Embodiment 3: prepare long glass fiber reinforced polypropylene (LGF-PP) material as follows:

[0047] 1. Preparation of raw materials

[0048] Long glass fiber (LGF40) specific gravity 1.22g / cm 3 , monofilament diameter 8μm, pure polypropylene fiber specific gravity 0.92g / cm 3 , single filament diameter 11μm, the weight of the pure polypropylene filter is 200g / m 2 The pure polypropylene filter mesh is 70 mesh, and the surface of the long glass fiber has been treated with 10% silane coupling agent kh550 to improve the compatibility between the long glass fiber and the polypropylene substrate.

[0049] 2. Preparation of materials for the guide rail of the integrated automobile window lifter:

[0050] (1) The long glass fiber and pure polypropylene fiber after fiber spreading are respectively cut into 100mm fiber segments, and the long glass fiber and pure polypropylene fiber are weighed according to the long glass fiber content of 70wt%, and placed on the comb needle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com