Sludge dewatering device and method combining screw propulsion and biomass electroosmosis

A technology of sludge dehydration and screw propulsion, which is applied in the direction of dehydration/drying/thickened sludge treatment, etc., which can solve the problems of high cost, difficulty in realization and high energy consumption of sludge treatment, so as to reduce moisture content, increase economic income, improve The effect of dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

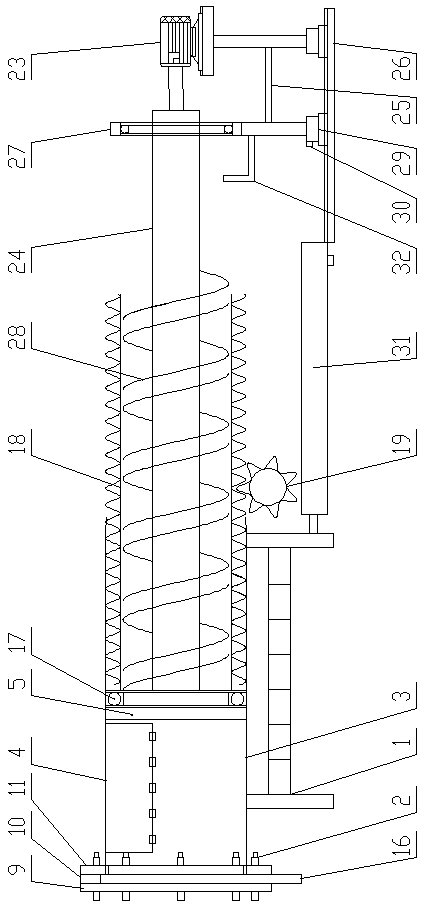

[0059] The traditional spiral propulsion electro-osmosis sludge dewatering treatment method mainly includes the following steps:

[0060] (1) Fully stir 3200 g of sludge in a mechanical stirrer and set aside.

[0061] (2) Fill the configured sludge into the sludge dehydration chamber 3 .

[0062] (3) Close the sealing cover plate 4, turn on the DC power supply, the anode electrode plate 5 does not rotate, and the hollow worm 18 continues to rotate to push the anode electrode plate 5 to squeeze the sludge to the left.

[0063] (4) Turn the driving rod 24 after the dehydration is completed, the blade 8 on the left side of the anode electrode plate 5 cuts off the sludge, and discharges all the sludge into the mud storage bucket 31 through the screw conveying blade 28, and takes a certain amount of sludge to test its moisture content and calorific value.

Embodiment 2

[0065] The traditional spiral propulsion electroosmosis combined with biomass sludge dehydration treatment method mainly includes the following steps:

[0066] (1) Fully stir 3200 g of sludge and 6% biomass in a mechanical stirrer, and set aside.

[0067] (2) Fill the configured sludge into the sludge dehydration chamber 3 .

[0068] (3) Close the sealing cover plate 4, turn on the DC power supply, the anode electrode plate 5 does not rotate, and the hollow worm 18 continues to rotate to push the anode electrode plate 5 to squeeze the sludge to the left.

[0069] (4) Turn the driving rod 24 after the dehydration is completed, the blade 8 on the left side of the anode electrode plate 5 cuts off the sludge, and discharges all the sludge into the mud storage bucket 31 through the screw conveying blade 28, and takes a certain amount of sludge to test its moisture content and calorific value.

Embodiment 3

[0071]The method of spiral propulsion electroosmosis combined with biomass sludge dehydration treatment mainly includes the following steps:

[0072] (1) Fully stir 3200 g of sludge and 6% biomass in a mechanical stirrer, and set aside.

[0073] (2) Fill the configured sludge into the sludge dehydration chamber 3 .

[0074] (3) Close the sealing cover plate 4, turn on the DC power supply, and the first motor reducer 20 drives the anode electrode plate 5 to rotate every once in a while, and the blade 8 on the left side of the anode electrode plate 5 cuts the adjacent anode electrode plate 5. Thinized sludge, the hollow screw continuously rotates and pushes the anode electrode plate 5 to squeeze the sludge to the left.

[0075] (4) Turn the driving rod 24 after the dehydration is completed, the blade 8 on the left side of the anode electrode plate 5 cuts off the sludge, and discharges all the sludge into the mud storage bucket 31 through the screw conveying blade 28, and takes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com