Low-cost production method for co-production of hypophosphorous acid and calcium hypophosphite

A production method, the technology of calcium hypophosphite, applied in the direction of hypophosphorous acid, phosphorus oxyacid, etc., can solve the problems of low cost, achieve the effects of reducing production cost, simple process, and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

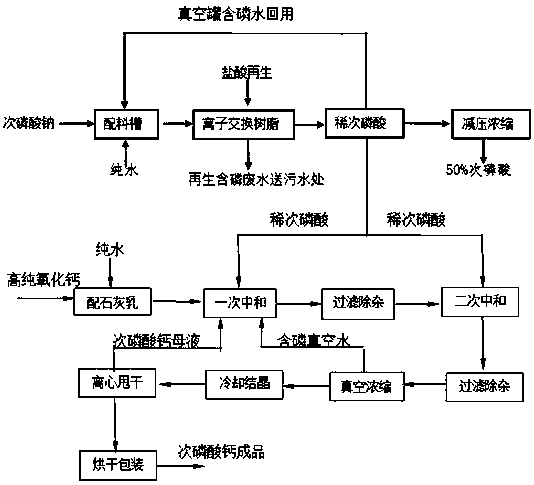

[0014] The technical solution of the present invention will be further described below according to the accompanying drawings.

[0015] Such as figure 1 Shown hypophosphorous acid co-production calcium hypophosphite low-cost production method, wherein the production method of hypophosphorous acid comprises the steps:

[0016] 1) Add sodium hypophosphite into the batching tank containing pure water, stir until the sodium hypophosphite crystals are completely dissolved to obtain a 17-18% sodium hypophosphite aqueous solution;

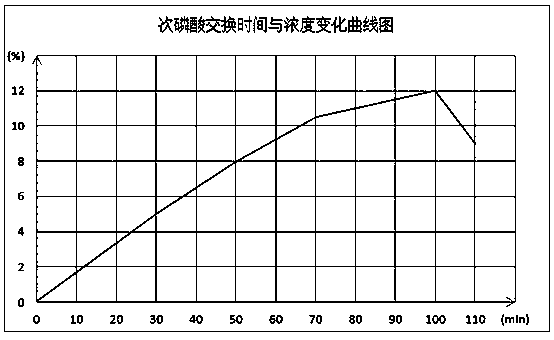

[0017] 2) Pass the sodium hypophosphite aqueous solution through 001×7 hydrogen-type strong acid ion exchange resin, and exchange sodium ions with hydrogen ions on the resin to obtain dilute hypophosphorous acid;

[0018] 3) Dilute hypophosphorous acid is pumped into the concentration kettle, and concentrated under vacuum under reduced pressure under the condition that the vacuum degree is greater than -0.5MPa, and the temperature of the material in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com