Architectural 3D printing cycle feeding control method and system

A 3D printing and control method technology, applied in manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of 3D printing quality influence and poor molding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

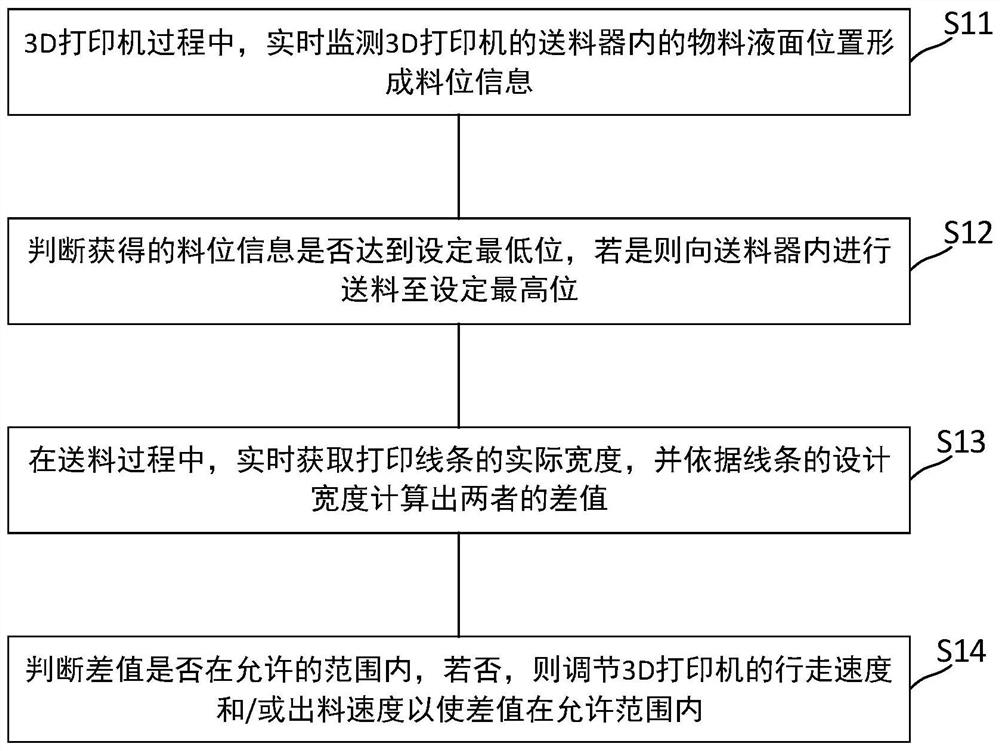

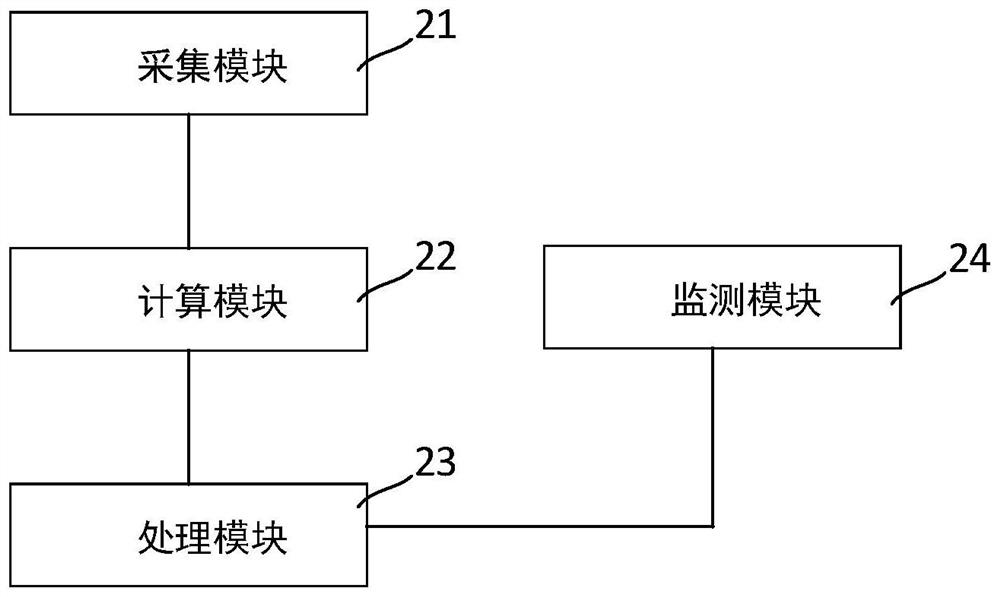

[0039] refer to figure 1 , the present invention provides a method and system for controlling the cyclic feeding of architectural 3D printing, which is used to realize the intelligent linkage control among the feeder, walking speed and discharging speed of the 3D printer, and is used to realize uniform discharging and ensure Printing quality, avoiding the problems of material breakage, uneven output and poor molding effect. During the feeding process, the difference between the actual width of the printing line and the design width is monitored in real time, and timely adjustment is made when it exceeds the allowable range, so as to reduce the impact of the feeding process on the printing quality and improve the 3D printing quality and molding effect. In the following, the method and system for controlling the circulating material supply of ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com