Clamping and moving mechanism for angle iron processing

A technology of moving mechanism and angle steel, which is applied in the direction of metal processing machine parts, metal processing equipment, clamping, etc., can solve the problems of low efficiency, heavy manual labor, poor effect, etc., and achieve good effect, convenient movement, and convenient manual or The effect of mechanical punching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

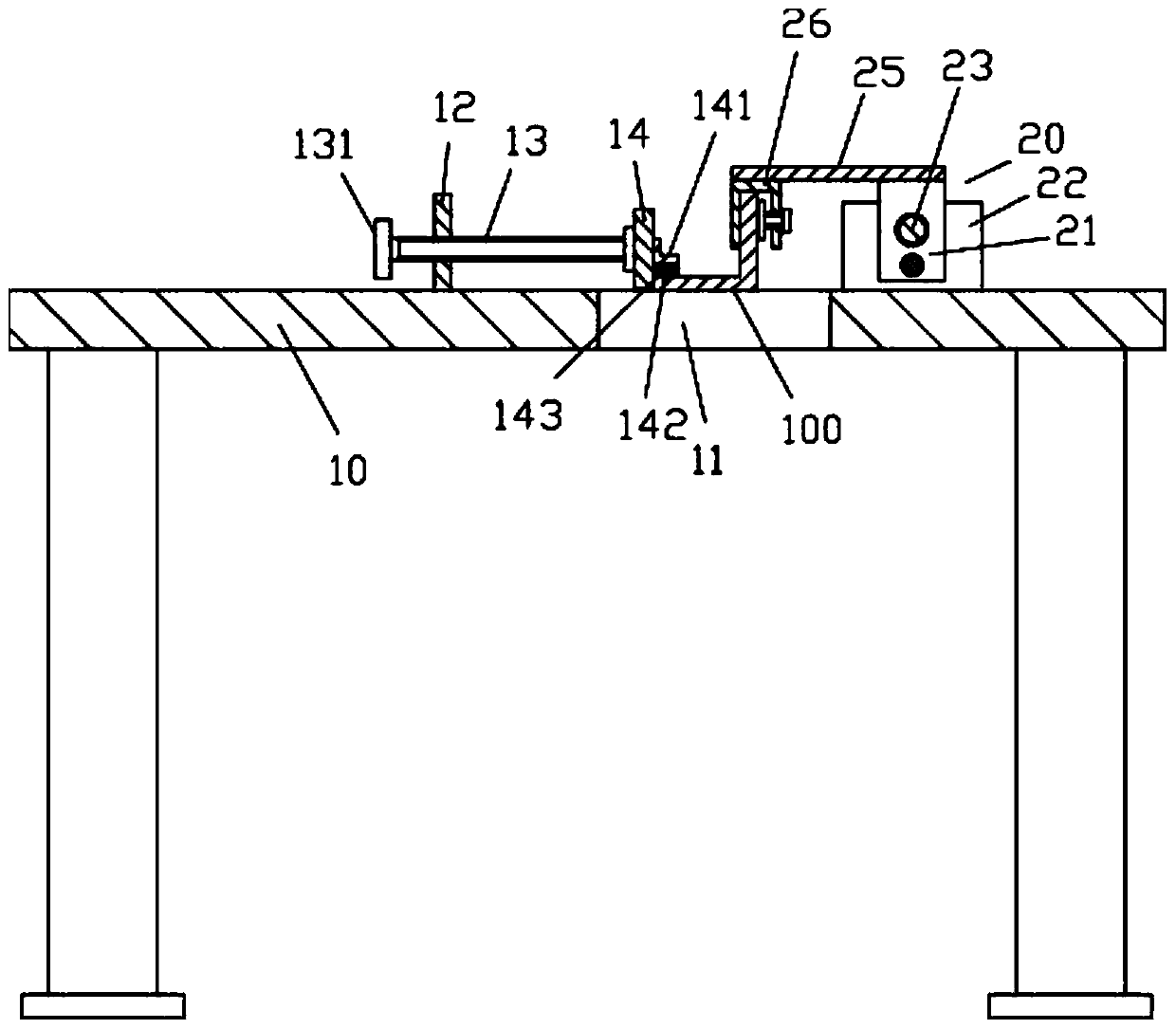

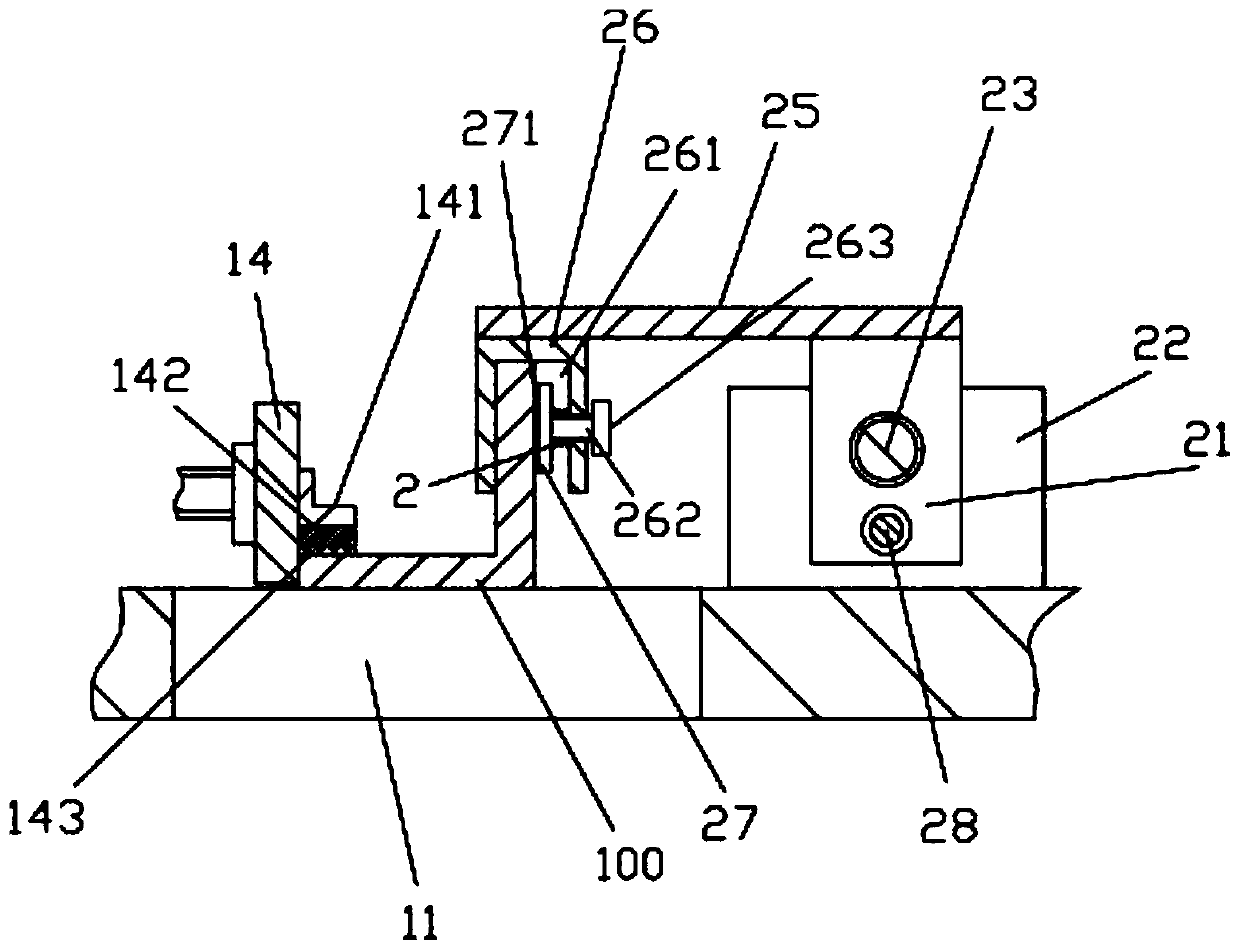

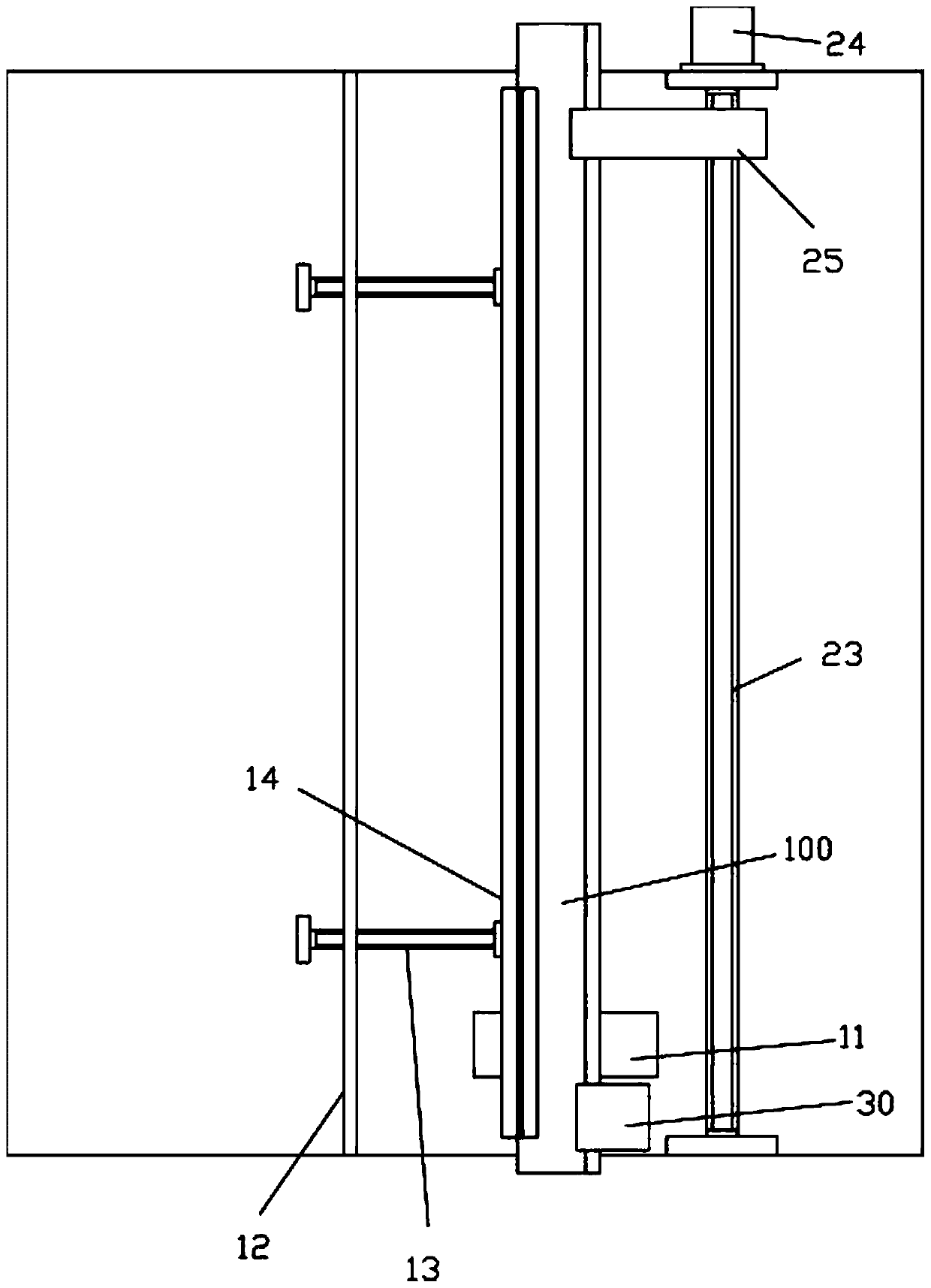

[0022] Examples, see e.g. Figure 1 to Figure 4 As shown, a clamping and moving mechanism for angle steel processing includes a frame 10, and the middle part of the front part of the top plate of the frame 10 has a through groove 11 for processing;

[0023] The left top surface of the top plate of the frame 10 is fixed with a side support plate 12, and the front and rear portions of the left side wall of the side support plate 12 are all screwed with adjusting screw rods 13, and the right ends of the two adjusting screw rods 13 pass through bearings. Hinged on the left side baffle plate 14, the left ends of the two adjusting screw rods 13 extend out of the side support plate 12 and are fixed with a rotating part 131, and the right side top surface of the top plate of the frame 10 is equipped with a clamping and moving mechanism 20;

[0024] The angle steel 100 to be processed is placed on the top surface of the top plate of the frame 10, the left side wall of the horizontal bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com