Multi-angle punching machine

A multi-angle, punching machine technology, used in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as affecting punching accuracy, complex procedures, affecting raw material positioning accuracy, etc., to improve work efficiency and simplify feeding. process, the effect of eliminating the sawing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below through specific examples.

[0043] For ease of description, in this solution, the raw material 10 is a square tube, but the square tube is not limited thereto.

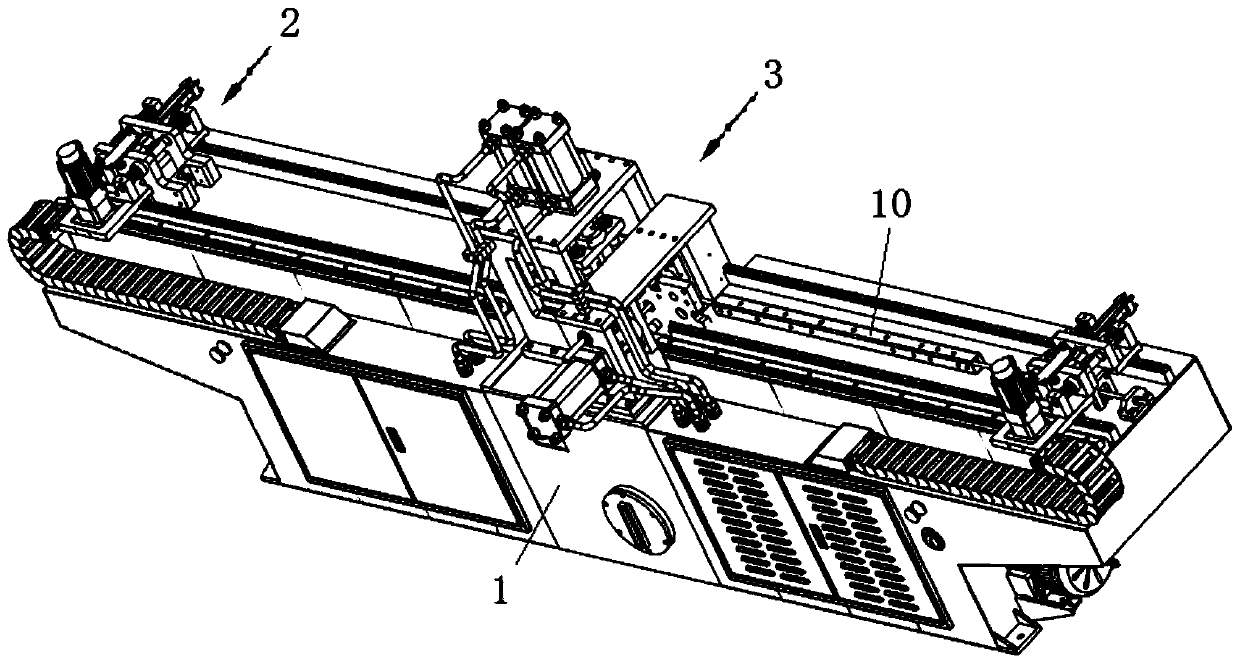

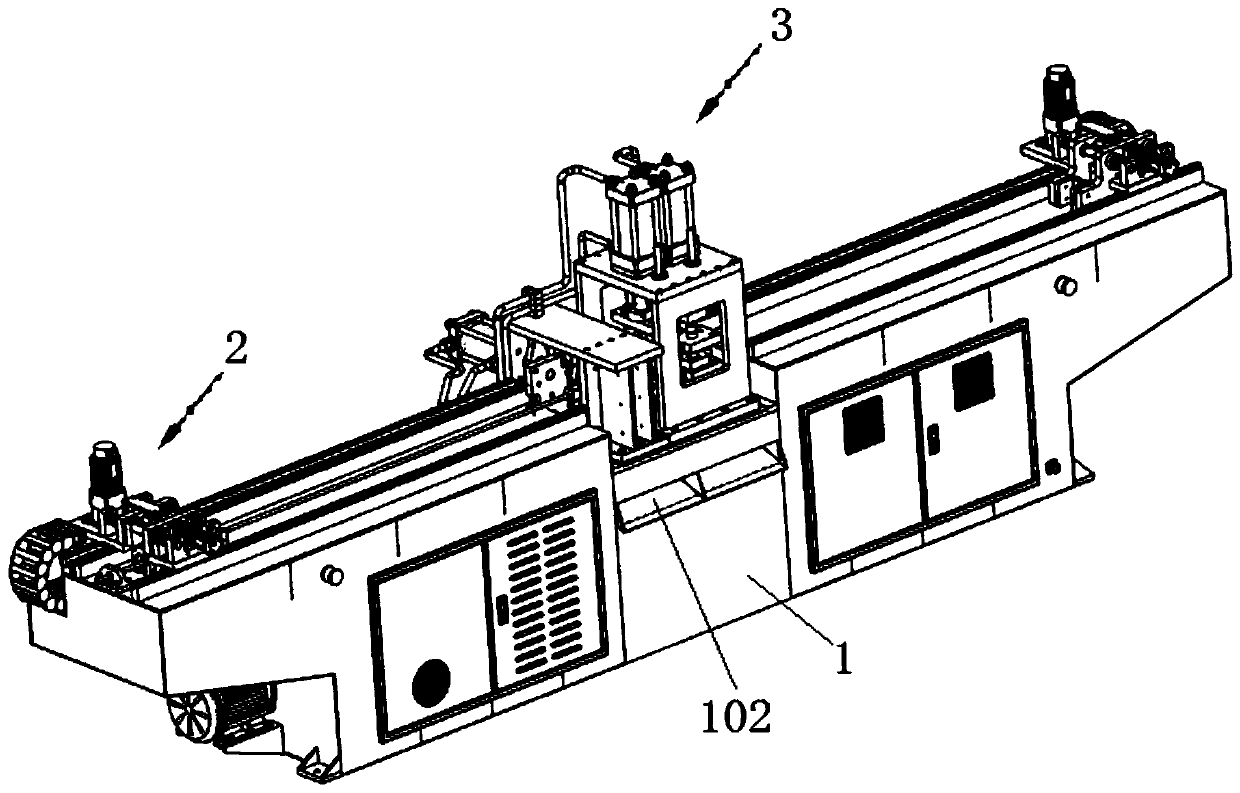

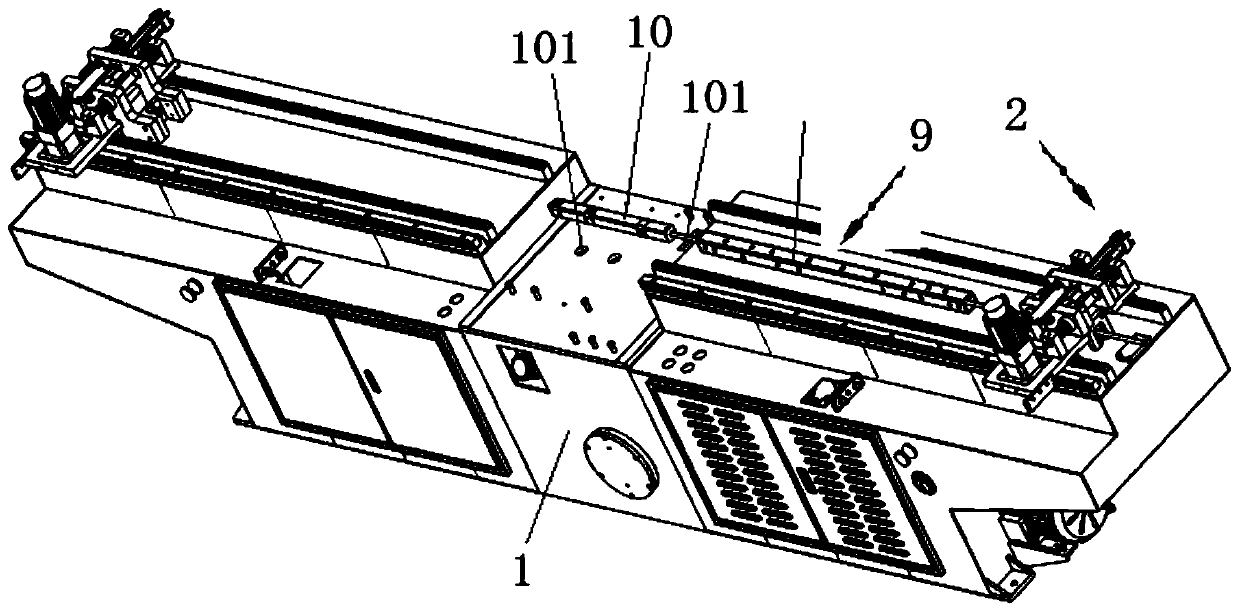

[0044] Such as Figure 1 to Figure 3 Commonly shown, a multi-angle punching machine, including a body 1, the two ends of the body 1 are slidingly installed with a raw material clamping and feeding mechanism 2, and the body 1 between the two raw material clamping and feeding mechanisms 2 is equipped with multiple Angle punching head 3, the multi-angle punching head 3 is provided with a raw material positioning and guiding mechanism 4, the raw material positioning and guiding mechanism 4 is provided with a mandrel 5, one end of the mandrel 5 is connected to the frame 1 A mandrel support mechanism 9 is provided between them, and the mandrel support mechanism 9 passes through a raw material clamping and feeding mechanism 2.

[0045] Such as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com