Steel coil longitudinal shearing flow quality control system and method based on cloud service

A technology of control system and cloud service, which is applied in the direction of rolling mill control device, tension/pressure control, metal rolling, etc. It can solve the problems of poor control accuracy of steel coil thickness, affecting the yield of finished products, and coil collapse, so as to improve the thickness of strip steel Thinning, improved control accuracy, and reduced cardioid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

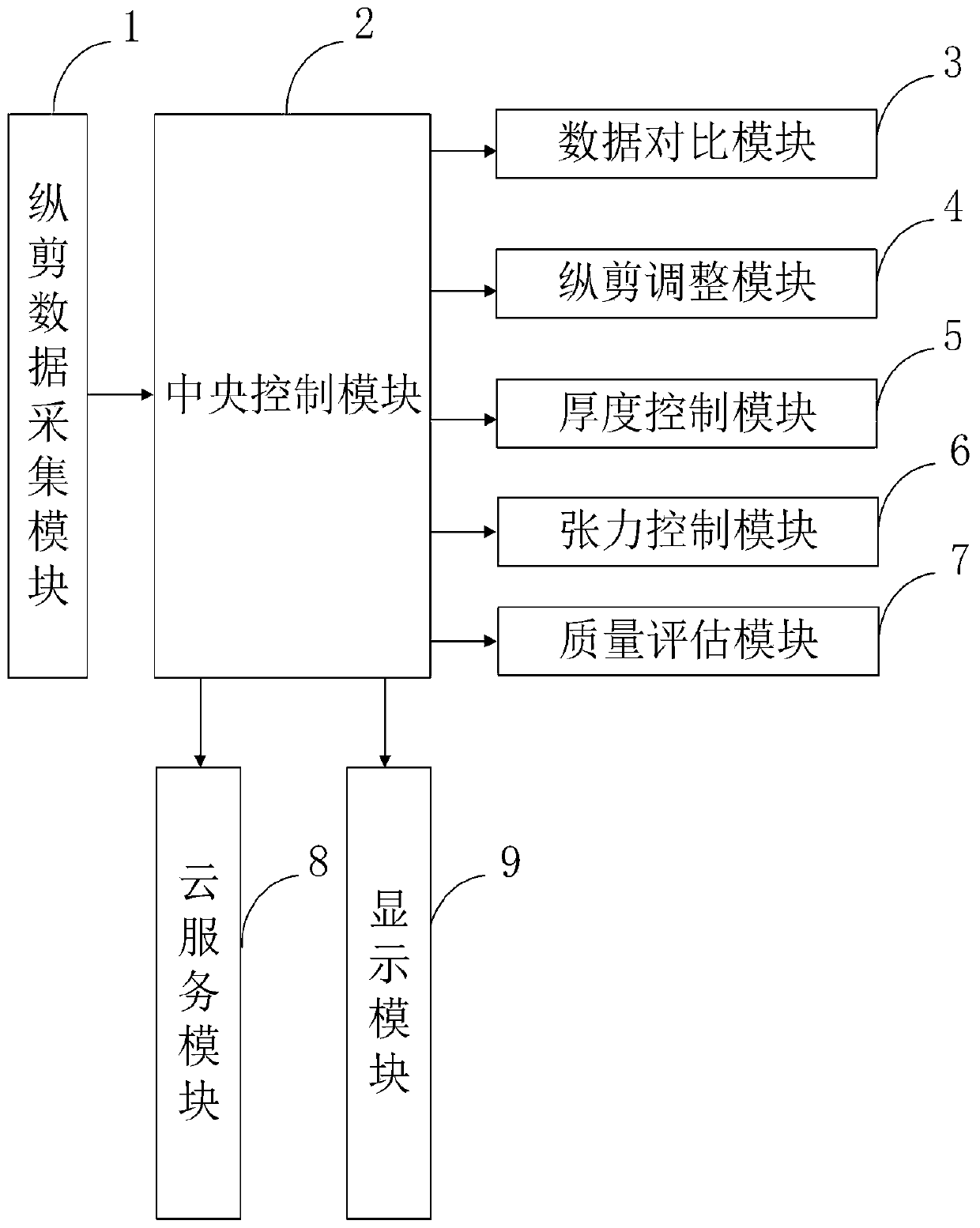

[0060] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0061] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

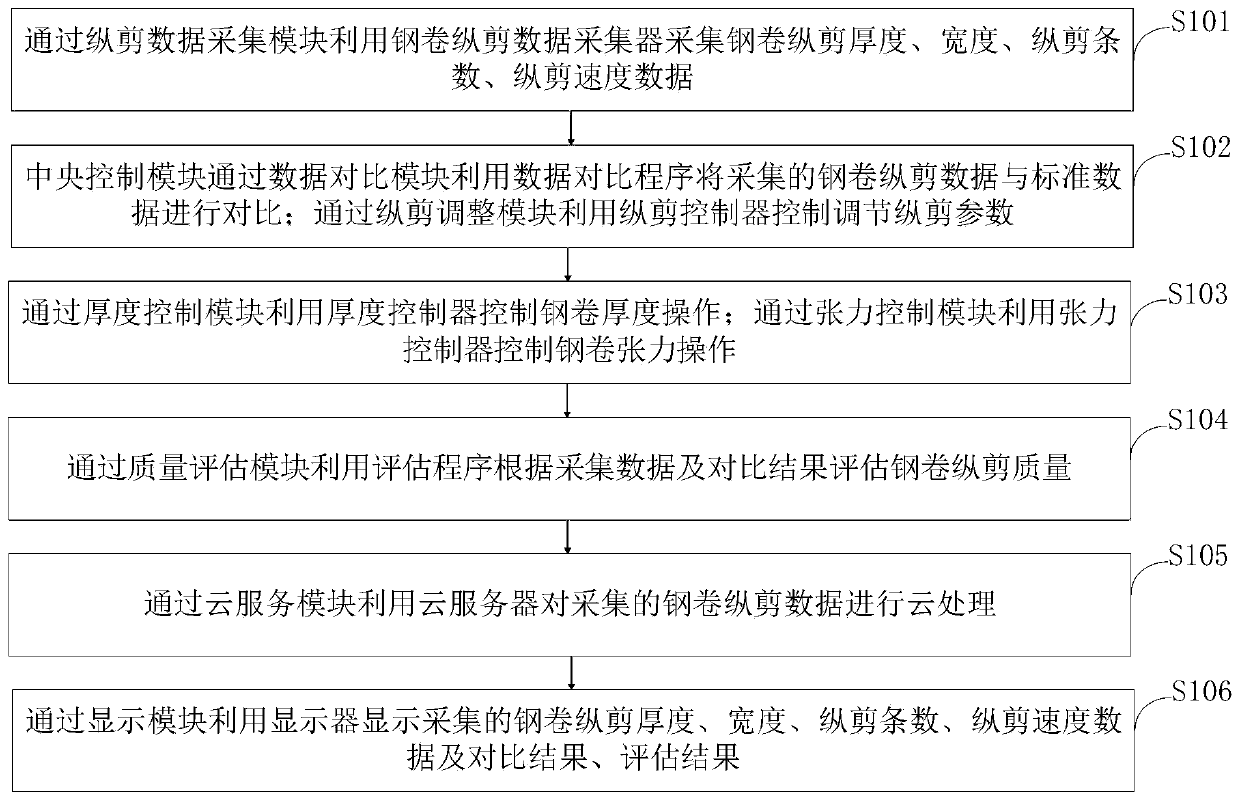

[0062] Such as figure 1 As shown, the cloud service-based steel coil slitting process quality control method provided by the present invention includes the following steps:

[0063] Step S101, using the coil slitting data collector to collect coil slitting thickness, width, slitting number, and slitting speed data through the slitting data acquisition module;

[0064] In step S102, the central control module compares the collected coil slitting data with the standard data through the data comparison module using the data comparison program; through the slitting adjustment module, the slitting controller is used to control and adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com