Polyimide Conductive Binder for Silicon-Based Anodes of Li-ion Batteries

A conductive binder and lithium-ion battery technology, applied in the manufacture of battery electrodes, secondary batteries, electrolyte batteries, etc., can solve problems such as inability to greatly increase energy density, low load capacity, unstable electrode structure, etc., and achieve technological The conditions are convenient and feasible, the energy density is improved, and the electrochemical performance is excellent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]The specific operation method of preparing conductive adhesive is as follows:

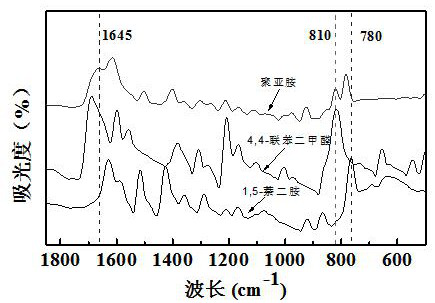

[0043] Add 0.4746g (3 mmol) of 1,5-naphthalene diamine and 0.631g (3 mmol) of 4,4-biphenyldicarbaldehyde into a three-necked flask, add 10ml of DMSO as a solvent, and stir evenly with magnetic force;

[0044] Vacuumize and then pass in argon, repeat three times, heat the oil bath and gradually raise the temperature to 90°C, and react for 12 hours to obtain a conductive adhesive solution.

[0045] The above solution was dialyzed 3 times with DMSO (the volume ratio of binder solution to DMSO was 1:100), and the excess solvent was removed by rotary evaporation, and then vacuum 75 o C and dried for 12 h to obtain the conductive adhesive product.

[0046] The concrete operation of preparing lithium-ion battery is as follows:

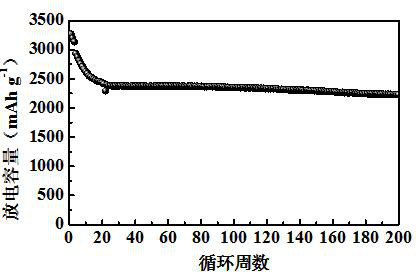

[0047] Weigh 0.05g of binder, add 8ml of NMP, and stir to disperse. Weigh 0.95 nanometer silicon, add it to the binder solution, and stir for 24 h to make the slurry even...

Embodiment 2

[0053] The specific operation method of preparing conductive adhesive is as follows:

[0054] Add 0.553g (3mmol) 4,4'-diaminobiphenyl and 1.261g (6mmol) 4,4-biphenyldicarbaldehyde into a three-necked flask, add 10ml of DMSO as a solvent, and stir evenly with magnetic force;

[0055] Vacuumize and then pass in argon, repeat three times, heat the oil bath and gradually raise the temperature to 60°C, and react for 12 hours to obtain a conductive polyimide binder solution.

[0056] Dialyze 3 times with DMSO (the volume ratio of binder solution to DMSO is 1:100), rotary evaporate to remove excess solvent, and then vacuum 75 o C and dried for 12 h to obtain the conductive polymer binder.

[0057] The concrete operation of preparing lithium-ion battery is as follows:

[0058] Weigh 0.05g of binder, add 8ml of NMP, and stir to disperse. Weigh 0.95g of nano-silicon, add it into the binder solution, and stir for 24 hours to make the slurry evenly mixed.

[0059] The obtained negativ...

Embodiment 3

[0064] The specific operation method of preparing conductive adhesive is as follows:

[0065] Add 0.276g (1.5mmol) 4,4'-diaminobiphenyl, 0.324g (1.5mmol) 3,3-dihydroxybenzidine and 0.631g (3mmol) 4,4-biphenyldicarbaldehyde into the three-necked flask, Add 10ml of DMSO as a solvent and stir evenly with magnetic force;

[0066] Vacuumize and then pass in argon, repeat three times, heat the oil bath and gradually raise the temperature to 100°C, and react for 12 hours to obtain a conductive polyimide binder solution.

[0067] Dialyze 3 times with DMSO, remove excess solvent by rotary evaporation, and then vacuum 75 o C and dried for 12 h to obtain the conductive polymer binder.

[0068] The concrete operation of preparing lithium-ion battery is as follows:

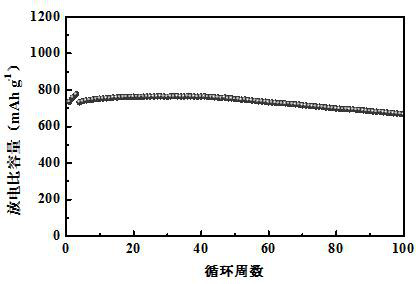

[0069] Weigh 0.05g of binder, add 8ml of NMP, and stir to disperse. Weigh 0.95 of the silicon-carbon composite negative electrode material, add it into the binder solution, and stir for 24 h to make the slurry evenly mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com