Green ultralight crack-resistant polyvinyl alcohol substrate and preparation method thereof

A technology of polyvinyl alcohol and polyvinyl alcohol powder, used in excavation, infrastructure engineering, construction, etc., can solve the problems of increased slope stability, soil erosion, increased slope load, etc., to reduce permeability and shrinkage properties, preventing soil erosion, and reducing the effect of slope loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

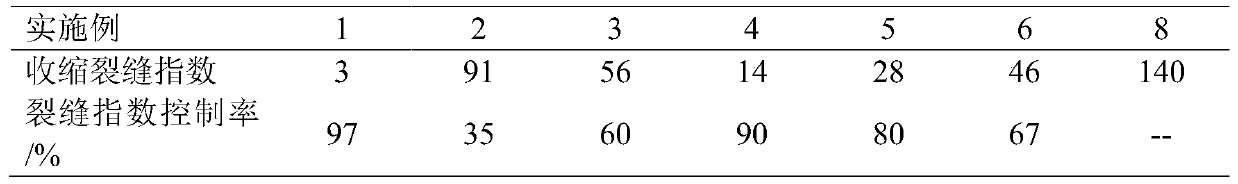

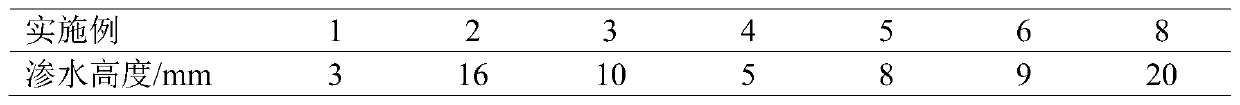

Embodiment 1

[0037] A preparation method for crack-resistant polyvinyl alcohol green ultra-light base material, comprising the following steps:

[0038] (1) Take Wuhan Xunsi River channel silt raw material soil, place it in an oven to dry, pass through a 1mm sieve, and set aside;

[0039] (2) Get 200 g of the raw soil sieved in the step (1), add 30 g of curing agent 42.5 ordinary Portland cement (the mass fraction is 15%, refers to the mass fraction of the raw soil, the same below), mix well ;

[0040] (3) add 140g water (mass fraction is 70%) in the mixture gained in step (2), then stir evenly with the speed of 110r / min in the mixer;

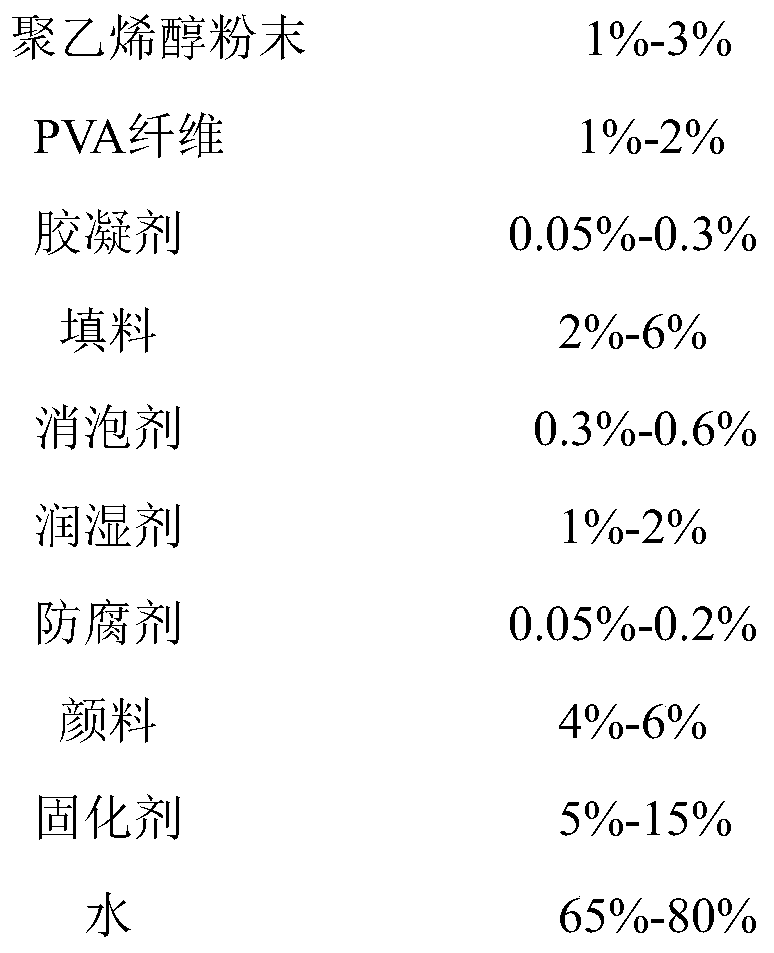

[0041](4) add polyvinyl alcohol powder, PVA fiber, gelling agent, filler, defoamer, wetting agent, preservative and pigment successively in the mixture of step (3) gained by certain dosage proportioning, then in Stir in the mixer at a constant speed of 70r / min for 15 minutes to form a crack-resistant polyvinyl alcohol green ultra-light substrate; the spec...

Embodiment 2

[0043] A preparation method of crack-resistant polyvinyl alcohol green ultra-light substrate, except that no PVA fibers are added in step (4); all the others are the same as in Example 1.

Embodiment 3

[0045] A kind of preparation method of crack-resistant PVA fiber green ultra-light base material, except not adding polyvinyl alcohol powder in step (4); All the other are all the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com