ti 4 o 7 Preparation method of coated ceramic microfiltration membrane electrode

A ceramic microfiltration and membrane electrode technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve the problems of high electrode cost and poor effect, and achieve The effect of long service life, simple production method and wide potential window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with embodiment:

[0032] Ti 4 o 7 The preparation method of the ceramic microfiltration membrane electrode of coating, comprises the following steps:

[0033] (1) Ti 4 o 7 Preparation of precursor sol:

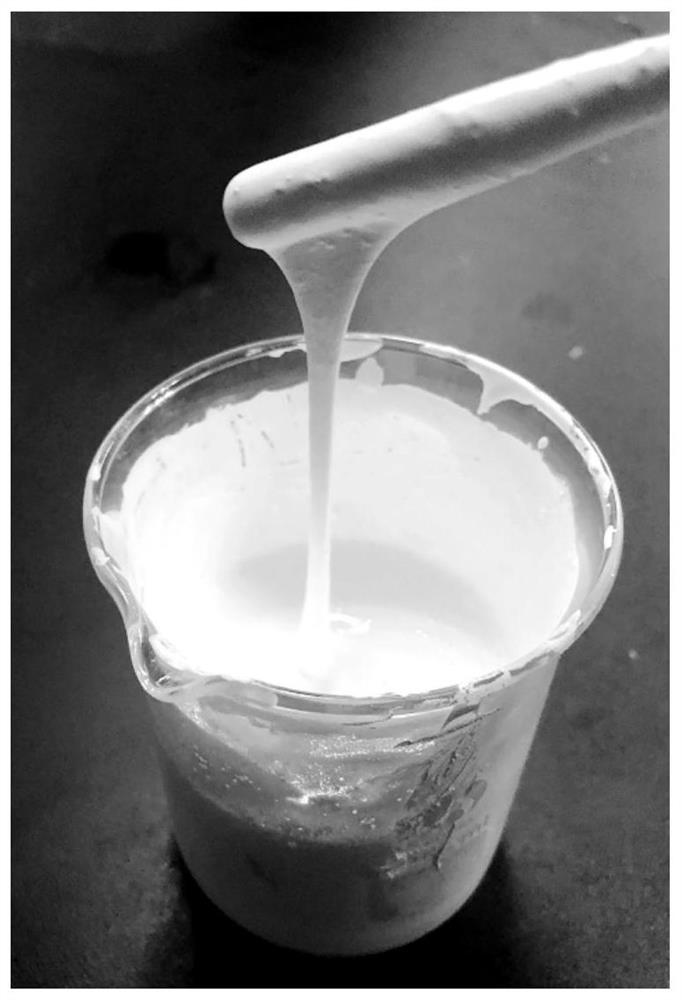

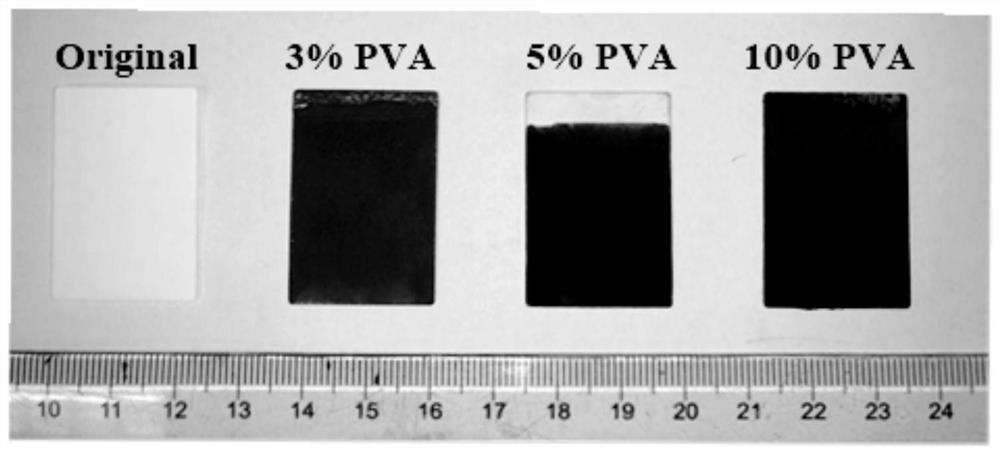

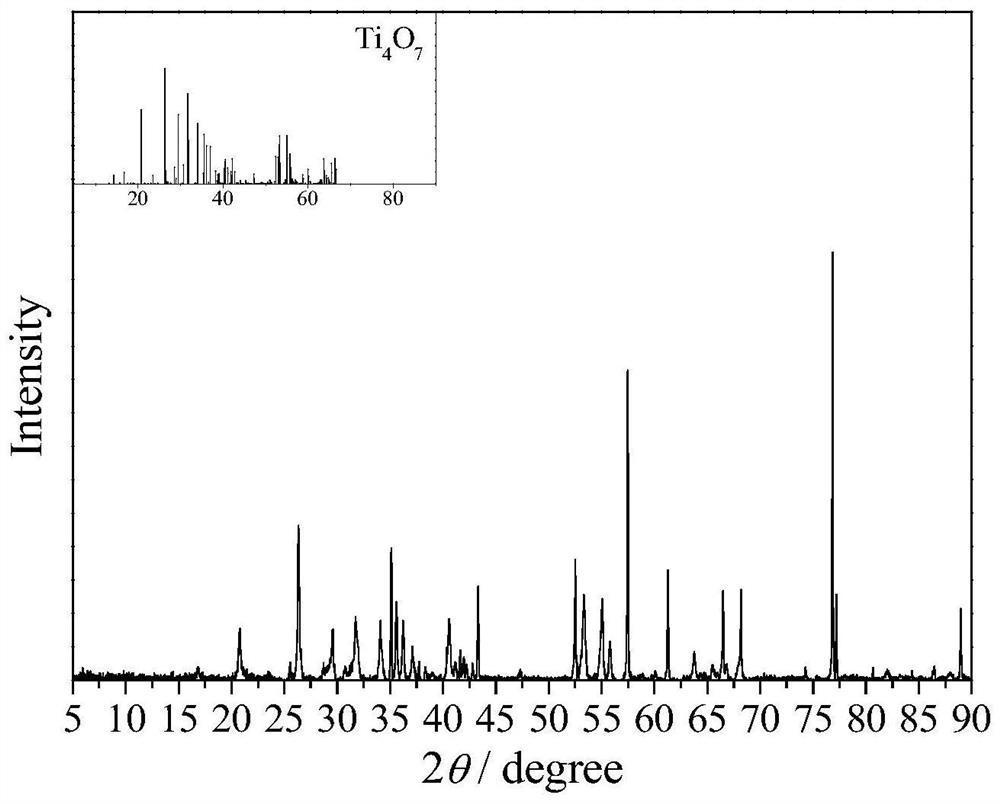

[0034] Put 10g of PVA in a beaker, pour deionized water to 100ml, and then place the beaker on a heating plate (IKA, RT-10) at 105°C to dissolve the PVA. During the dissolution process, add an appropriate amount of deionized water to supplement deionization Evaporation loss of water; add 20g TiO accordingly after cooling 2 , 2gPAA, 1.5g glycerol and 1.2gPVP and stirred, finally dilute to 100ml with deionized water; mechanically stir the sol with a stirrer (IKA, RW-20) at 900rpm to enhance TiO 2 Dispersibility in the sol, Ti can be obtained after stirring 4 o 7 Precursor sol;

[0035] (2) Ti 4 o 7 Preparation of precursor gel-coated ceramic microfiltration membranes:

[0036] Ti ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com